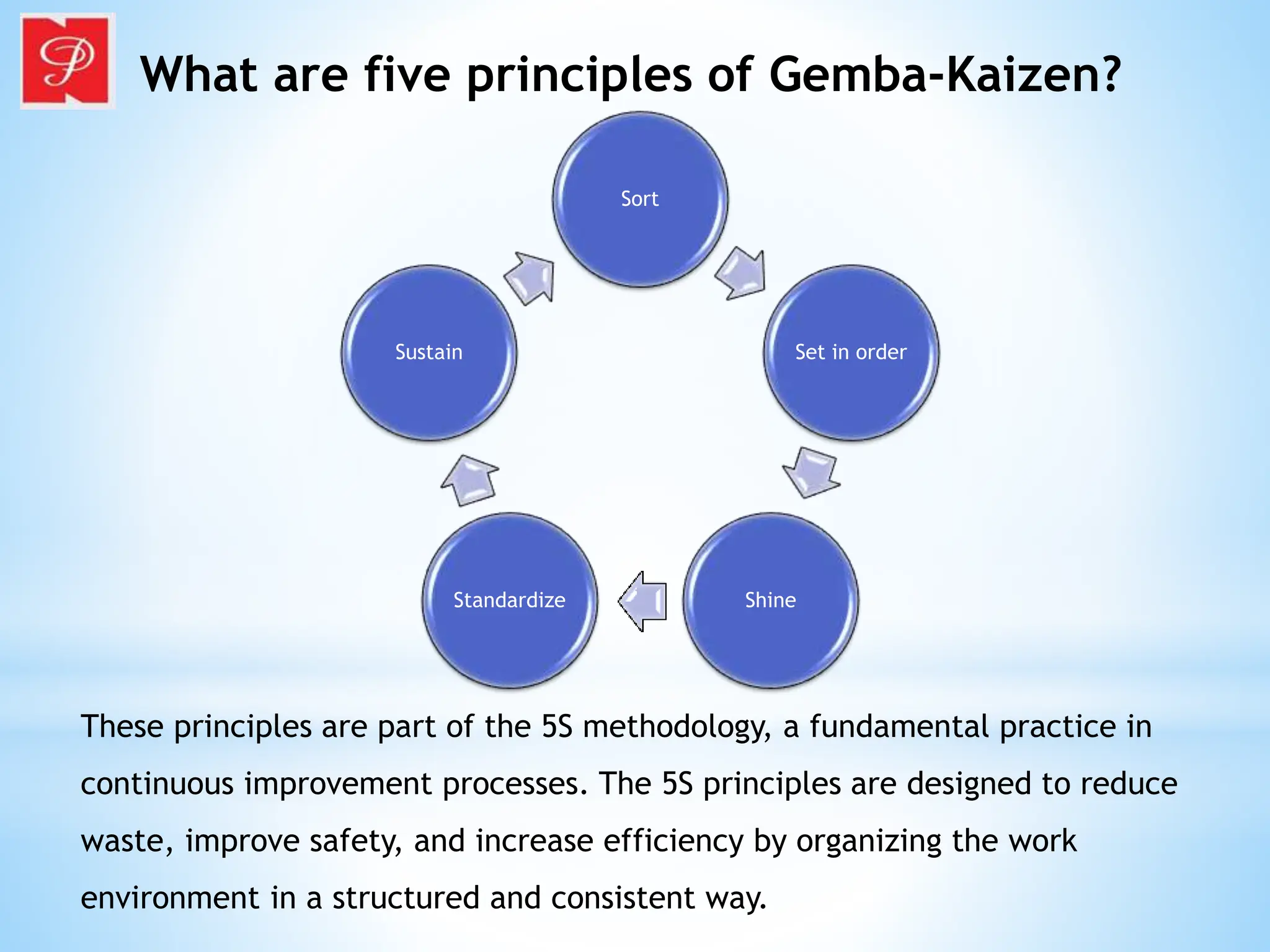

The gemba walk is a physical visit to the front line of operations to identify process improvements, rooted in lean manufacturing principles. The term 'gemba' means 'the real place' in Japanese, emphasizing the importance of observing work where it happens. Benefits of gemba walks include increased employee engagement, higher morale, better communication, and improved customer satisfaction, guided by principles such as going to see, asking why, and showing respect.