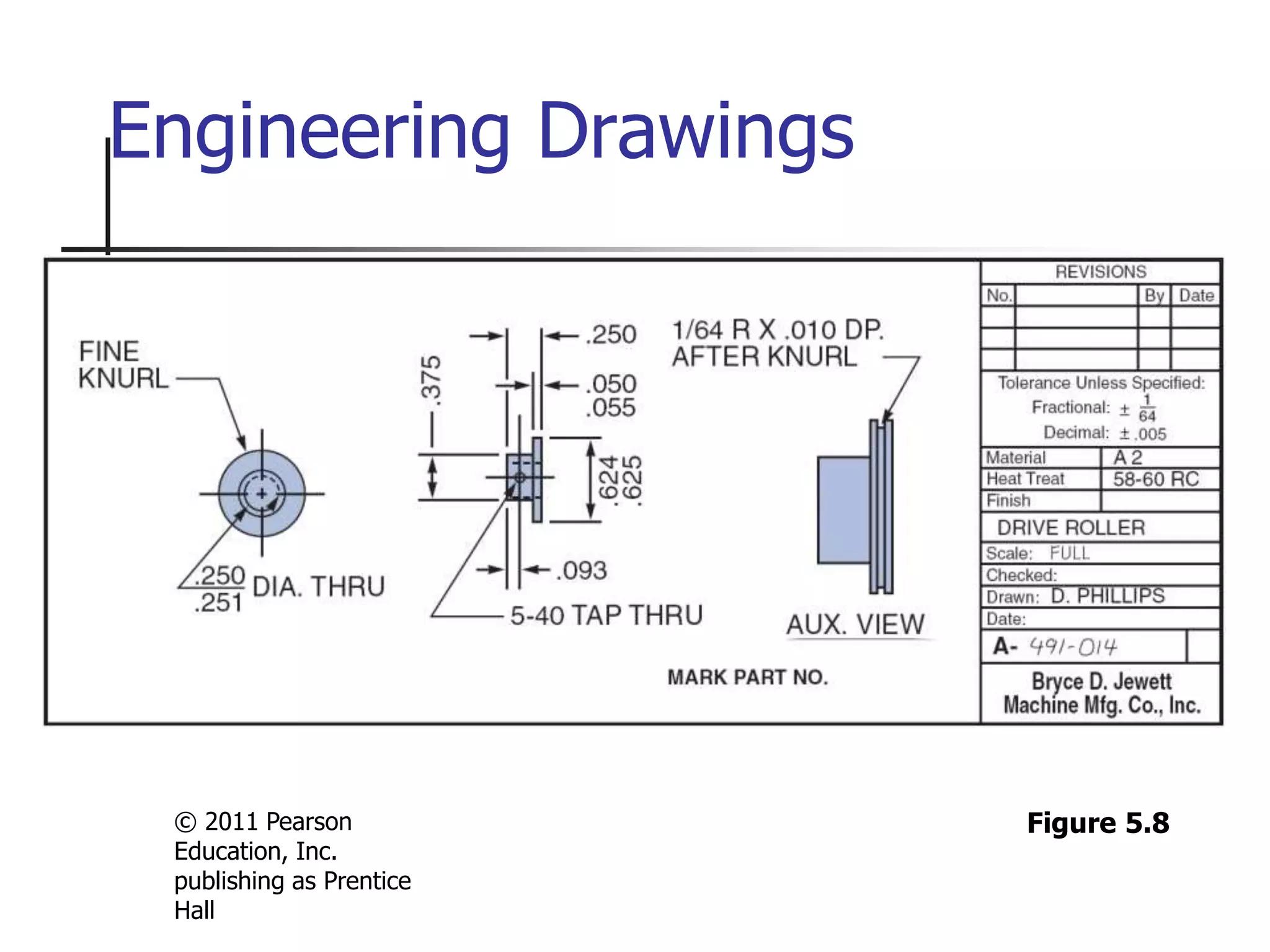

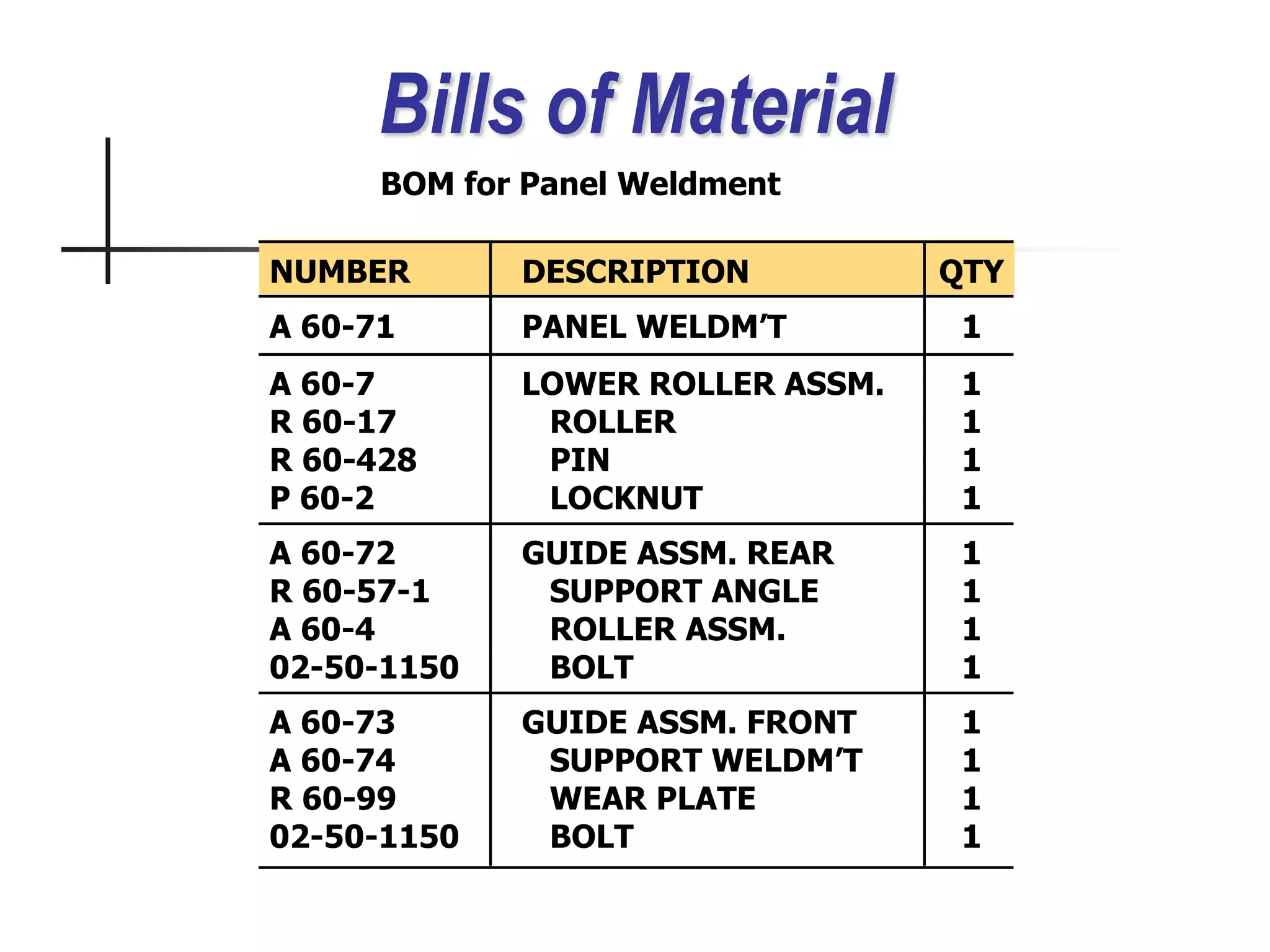

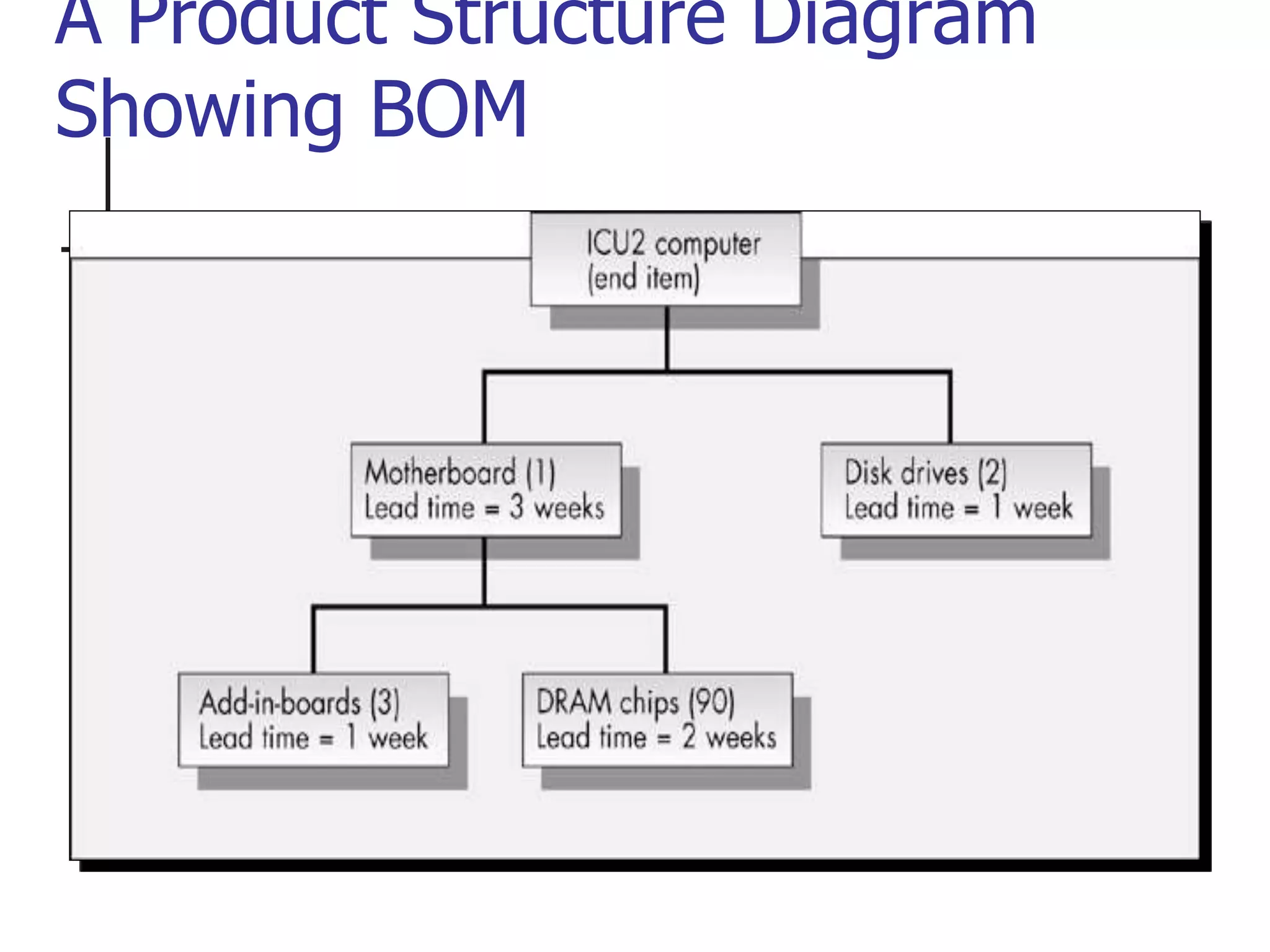

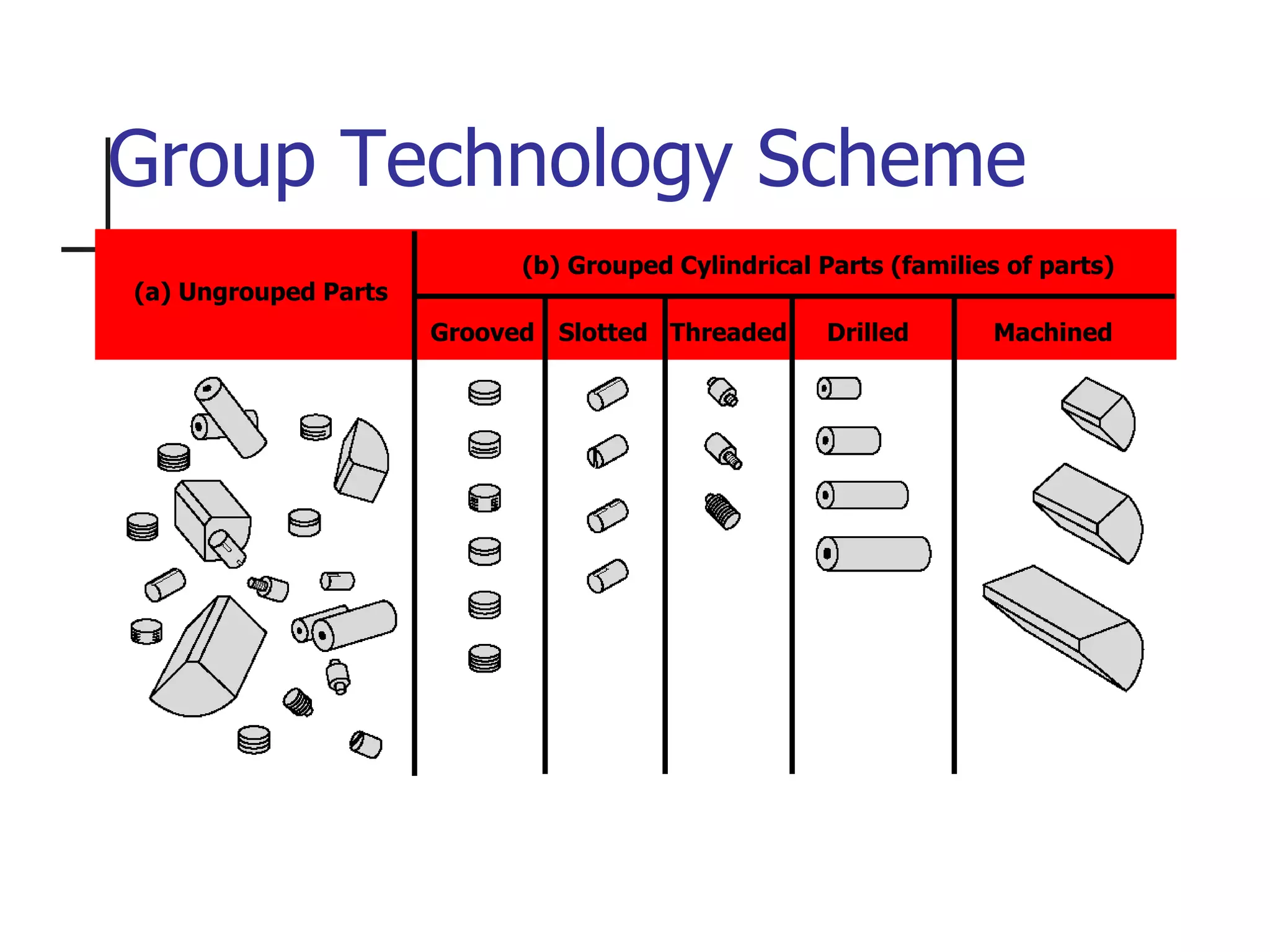

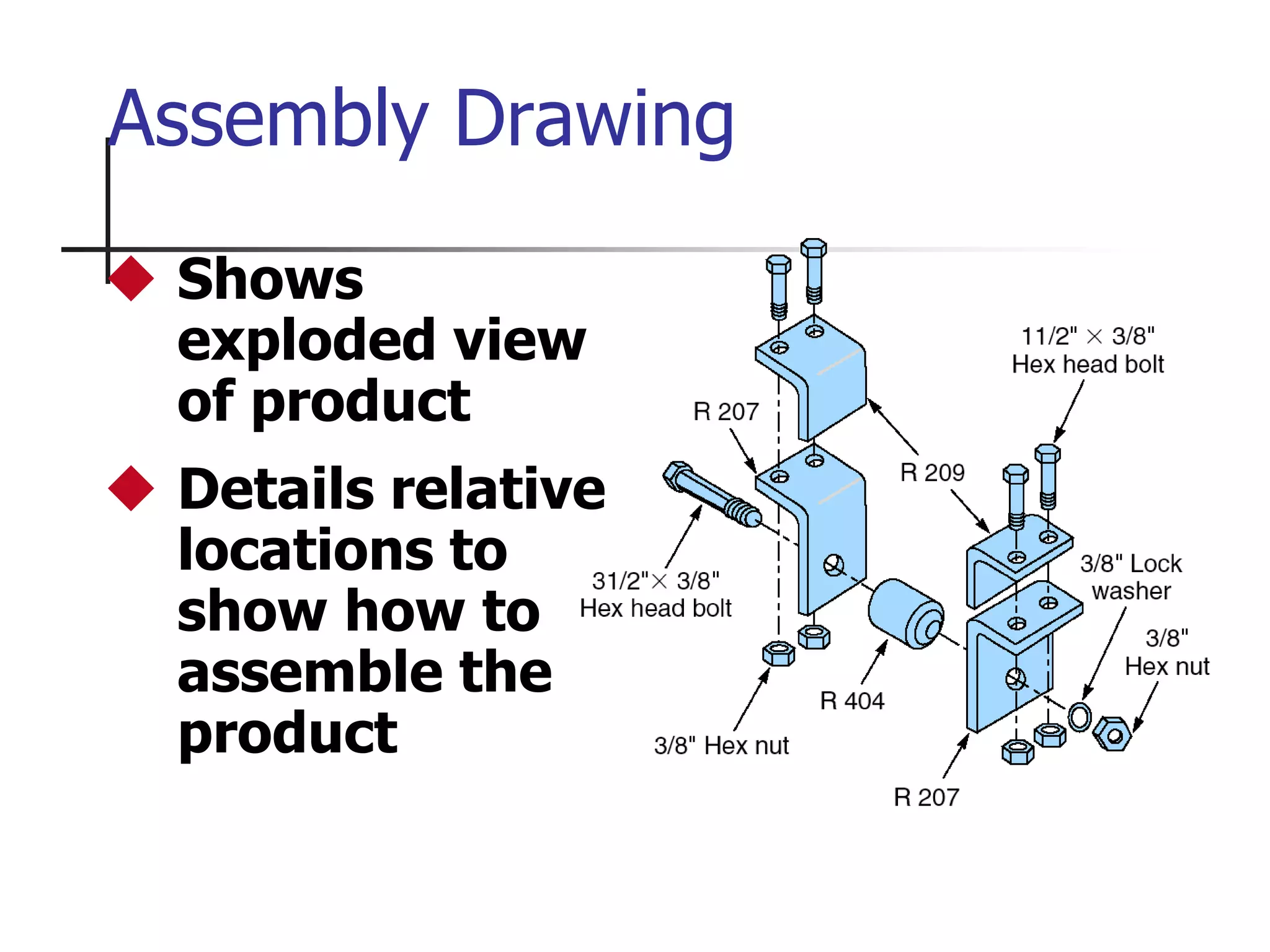

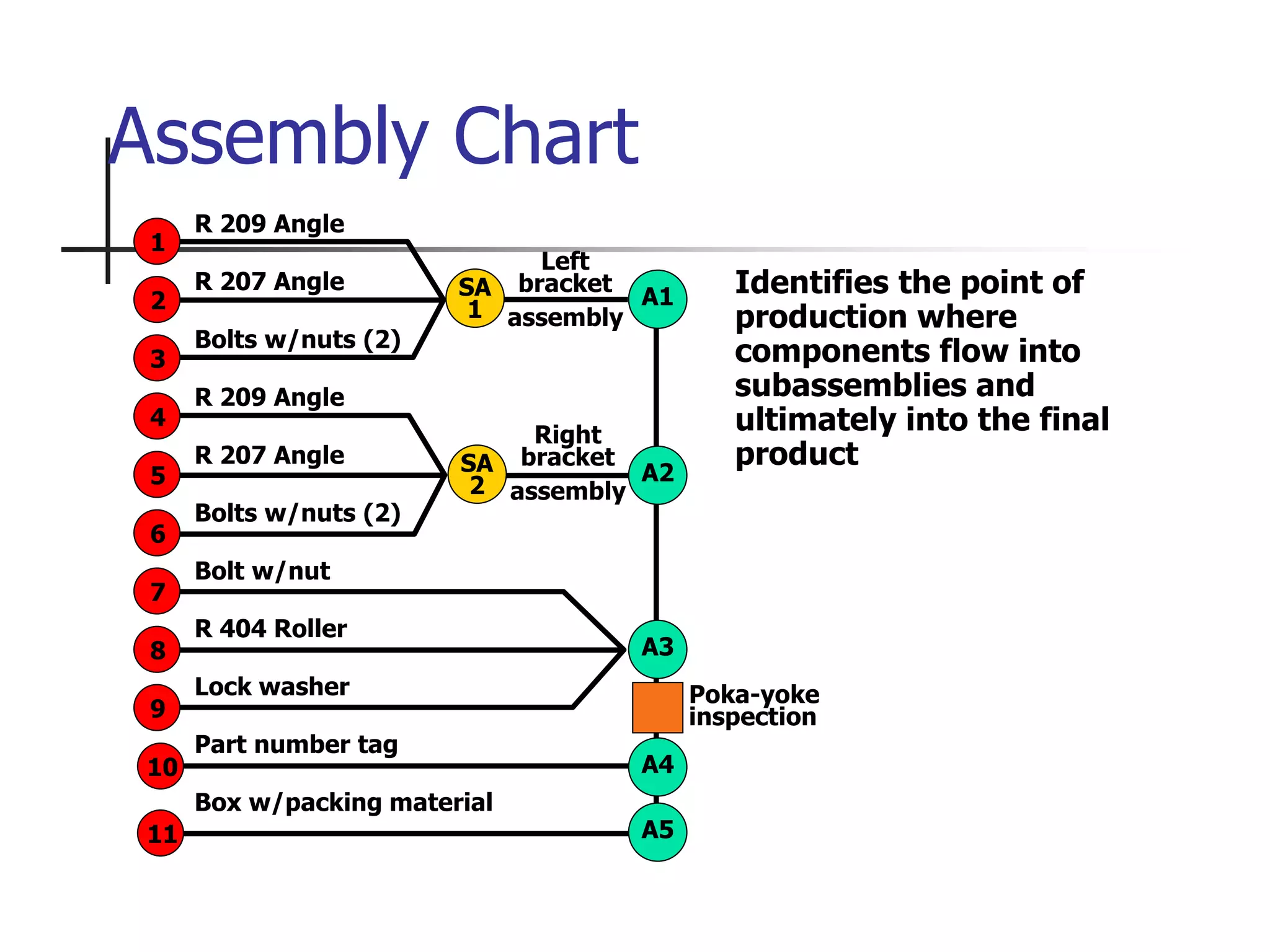

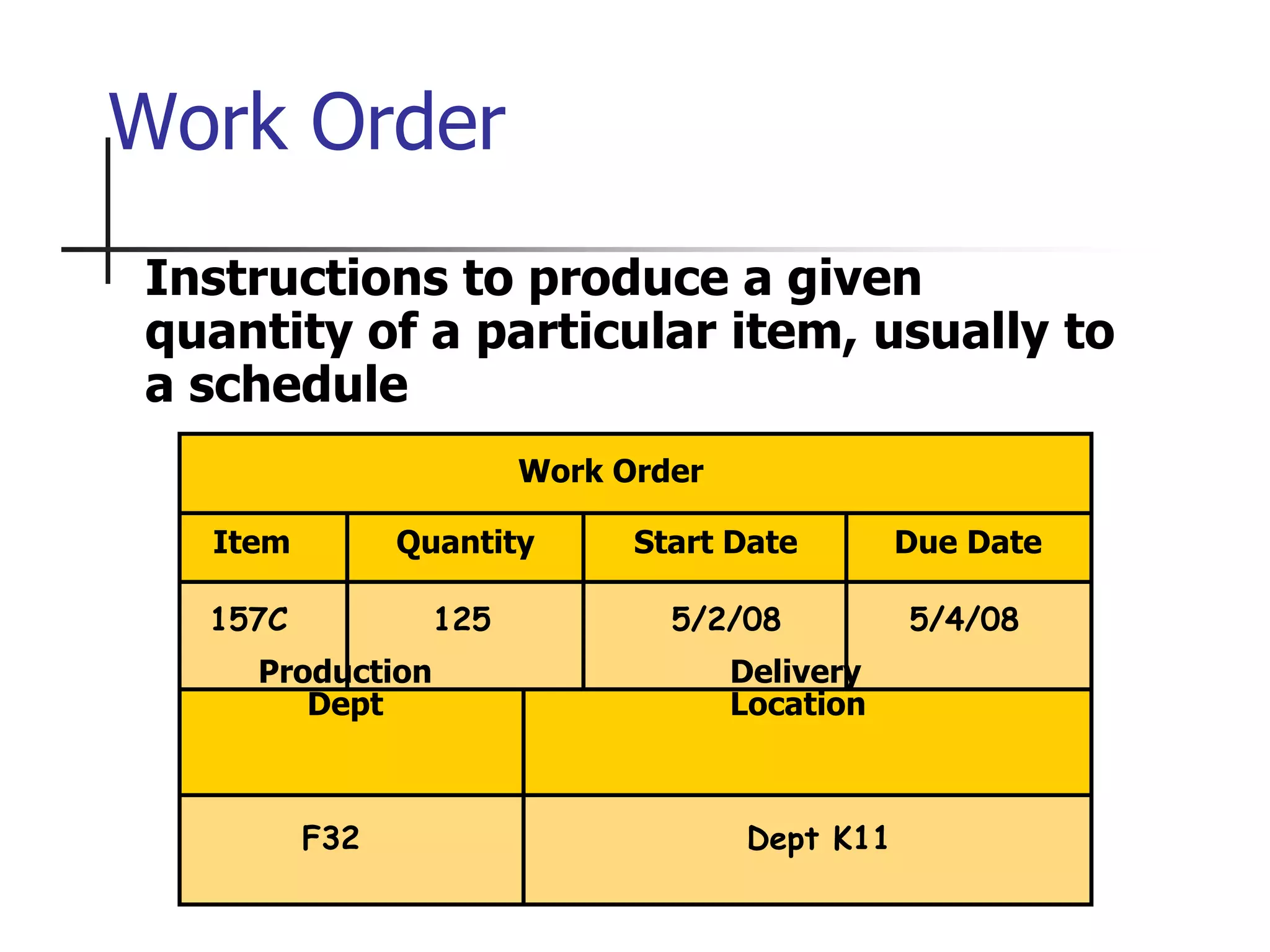

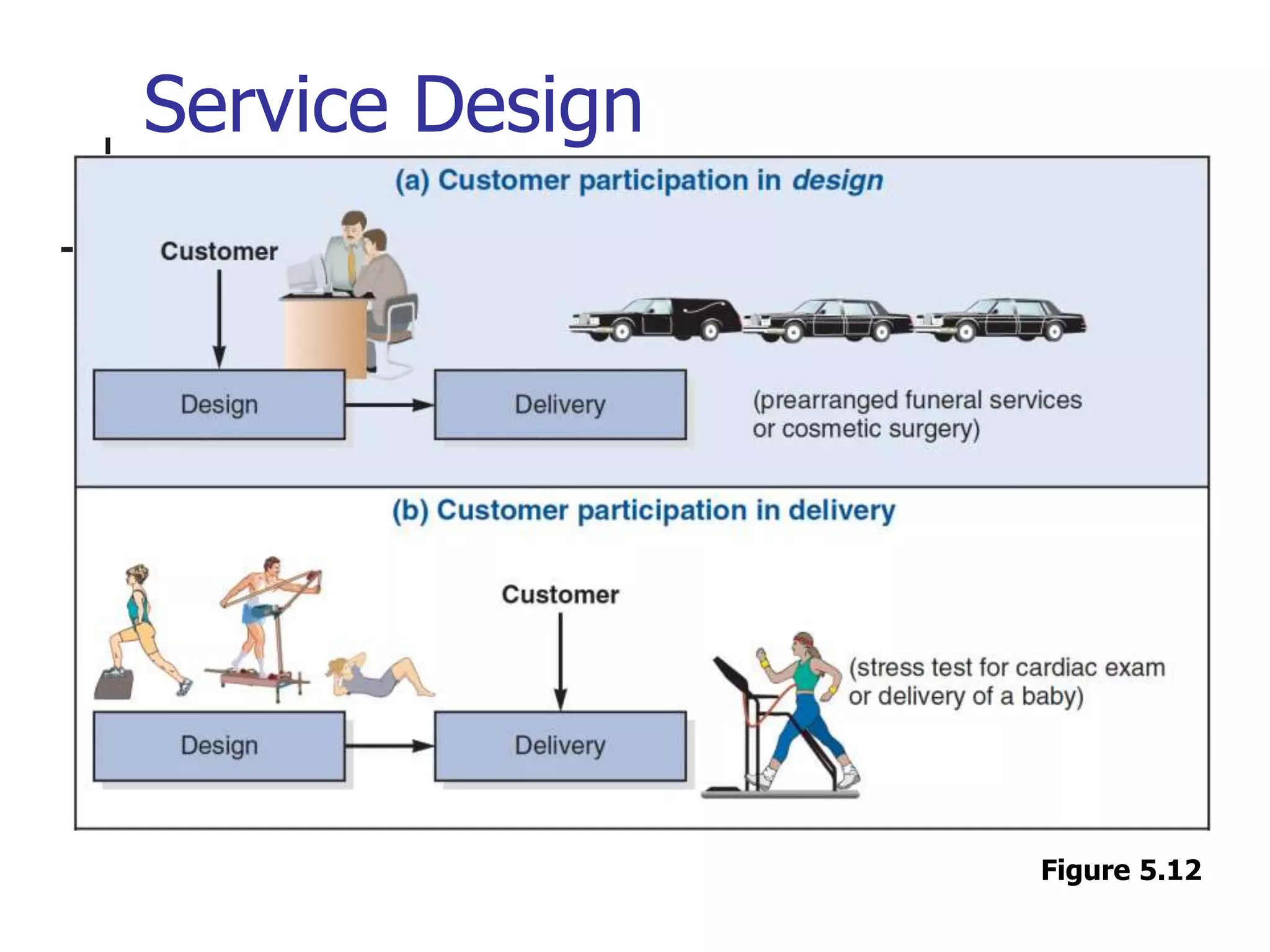

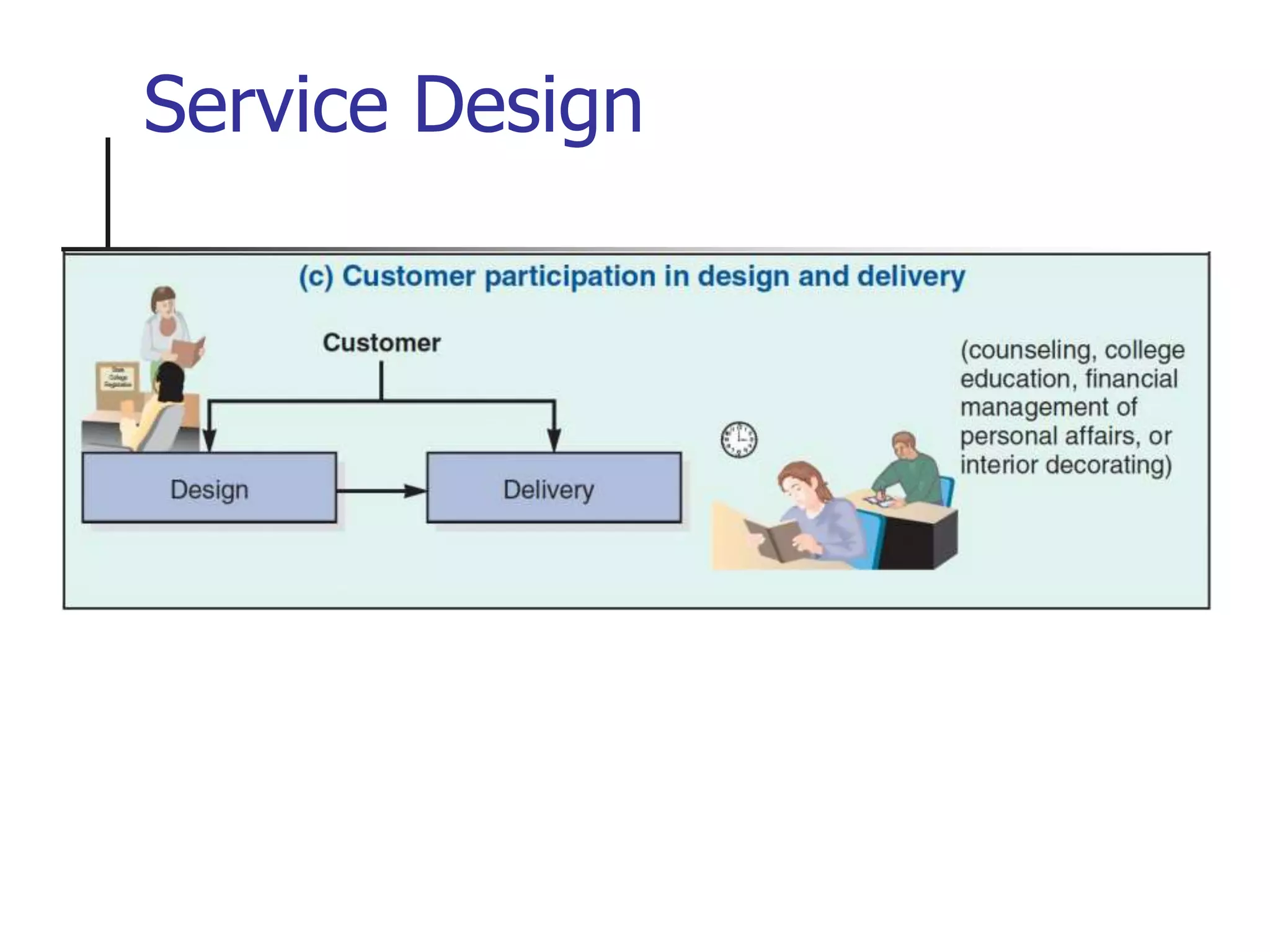

The document discusses new product development and competitive advantage through products and services. It covers key aspects of the product development process including design, quality, issues like robust and modular design, and computer-aided design and manufacturing. It also discusses defining the product for manufacturing through engineering drawings, bills of materials, group technology, and production documents. Service design is briefly covered as well. The objective is to develop a product strategy that meets market demands and provides a competitive advantage.