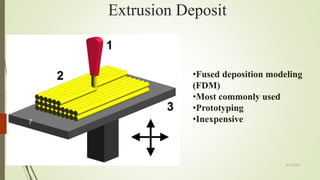

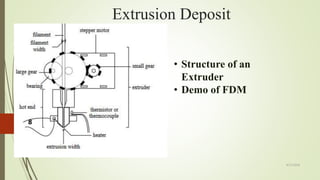

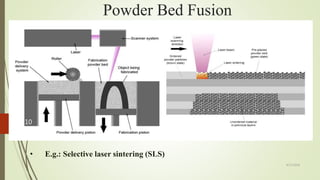

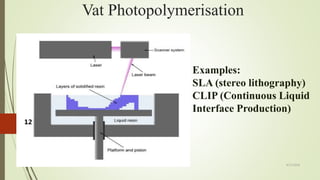

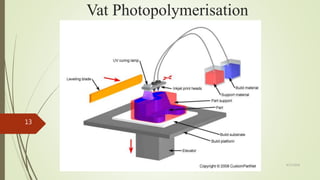

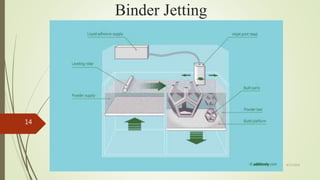

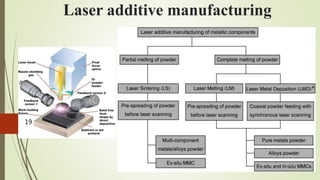

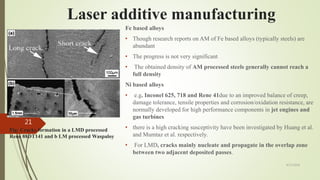

The document discusses various types of additive manufacturing (3D printing) technologies. It describes extrusion deposit techniques like fused deposition modeling (FDM), powder bed fusion methods including selective laser sintering (SLS), and vat photopolymerization techniques like stereolithography (SLA). It also covers areas like binder jetting, 3D model file formats, applications in advanced manufacturing and medicine, and challenges with additively manufacturing metal matrix composites.