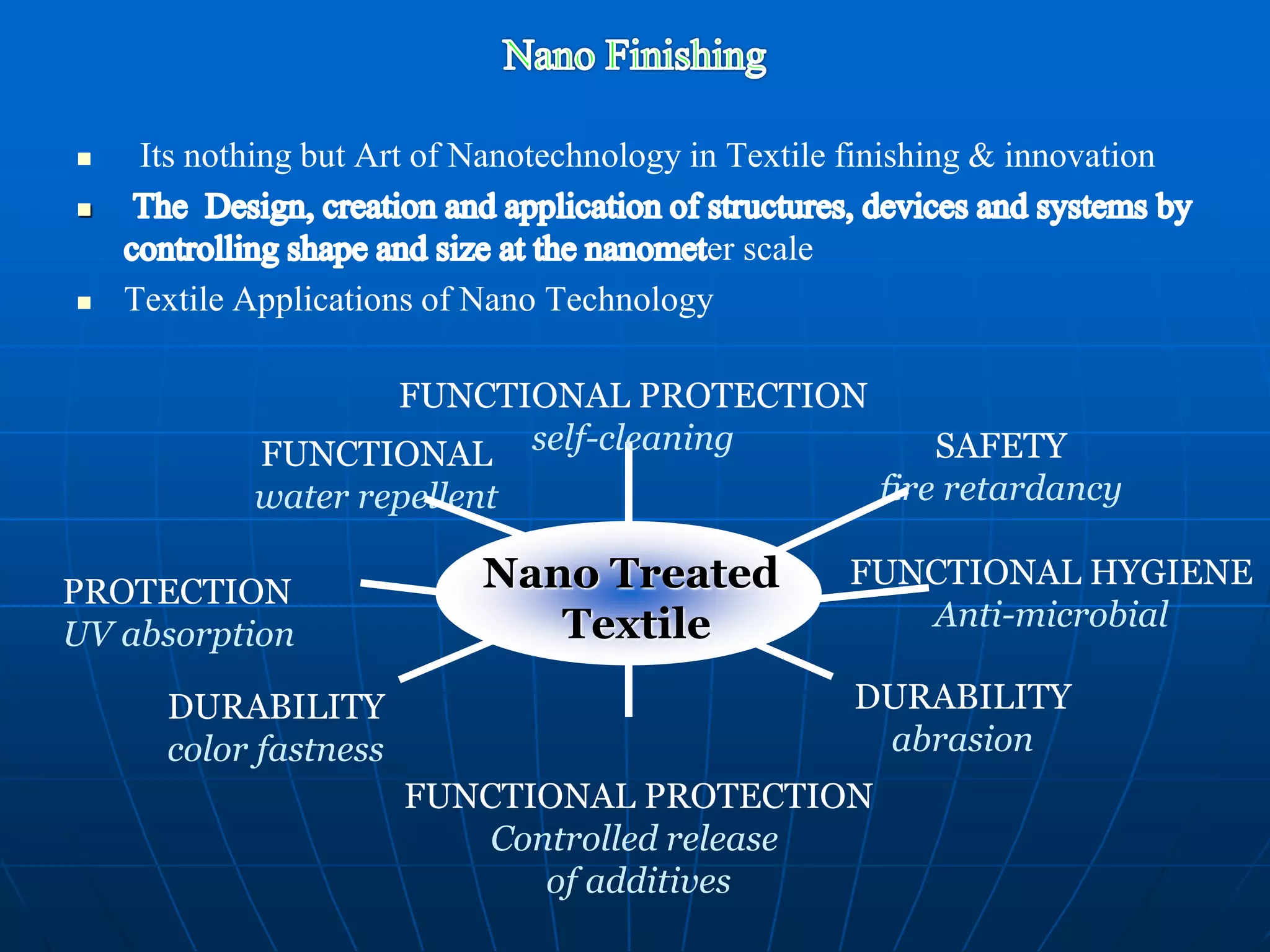

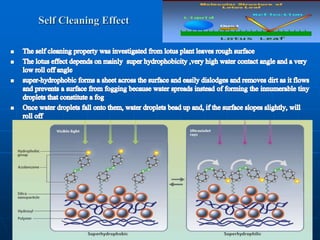

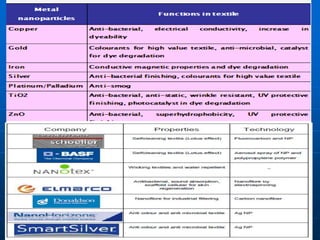

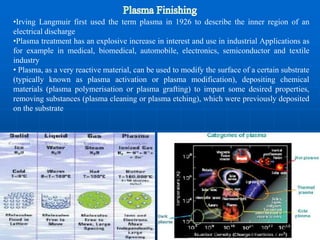

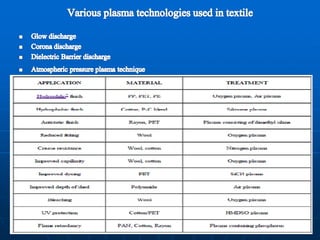

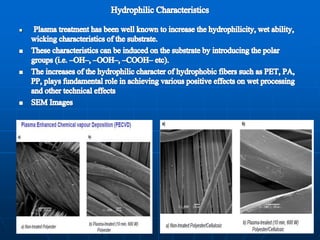

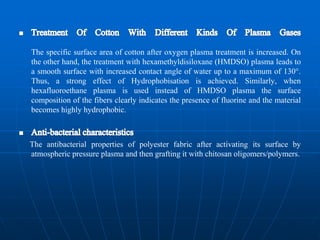

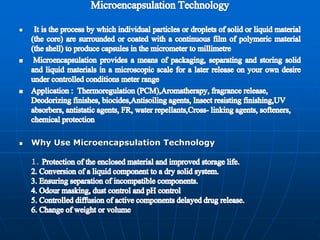

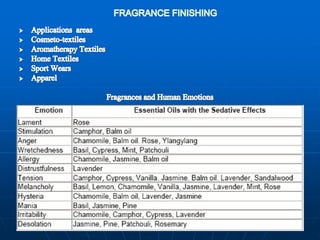

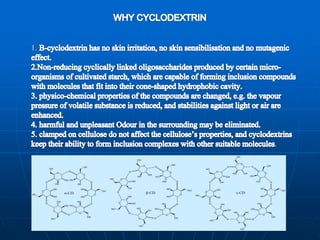

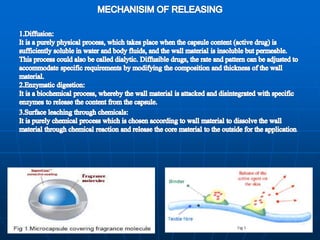

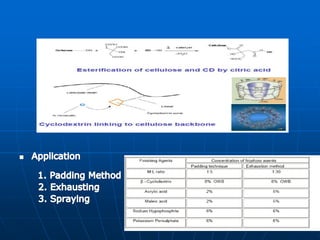

This document discusses the use of nanotechnology in textile finishing and innovation. It outlines several textile applications of nano technology including making materials water repellent, providing UV absorption and protection, improving durability and abrasion resistance, adding fire retardancy, enabling anti-microbial properties, and allowing controlled release of additives. The document also discusses using plasma treatment and microencapsulation technology to functionalize textiles by making them hydrophobic, antibacterial, or able to release fragrances over time.