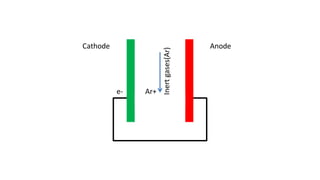

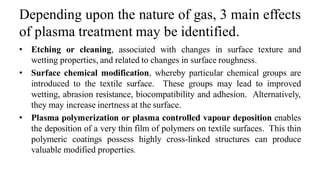

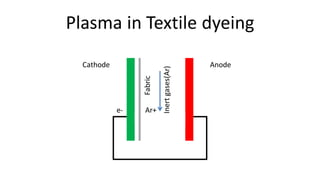

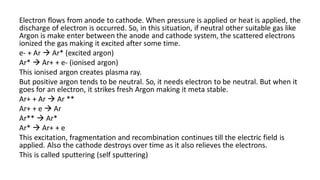

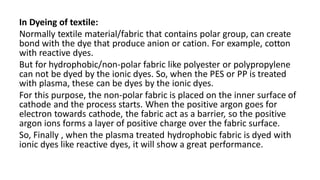

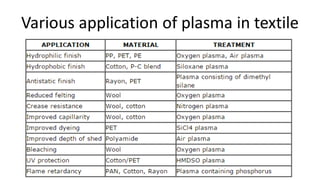

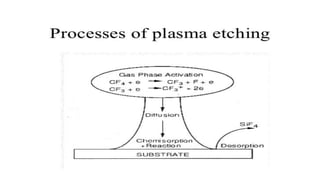

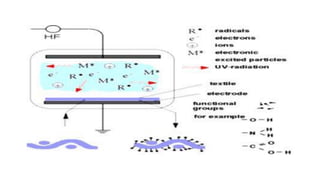

Plasma dyeing technology uses plasma to modify the surface of non-polar fabrics like polyester and polypropylene so they can be dyed with ionic dyes. Plasma is generated by applying an electric field to a low-pressure gas, which ionizes the gas particles. When non-polar fabrics are placed in a plasma chamber, the positive ions deposit on the fabric surface, giving it a positive charge and allowing it to bond with anionic dyes. Plasma treatment introduces new functional groups on fabric surfaces, altering properties like wettability and facilitating graft polymerization or thin film deposition to further modify the fabric. Different plasma generation methods like glow discharge, corona discharge, and dielectric barrier discharge are used for