The document discusses different metal joining processes including brazing, soldering, and welding. It provides details on:

- Brazing involves melting a higher-temperature filler metal without melting the base metals. Soldering uses a lower-temperature filler metal.

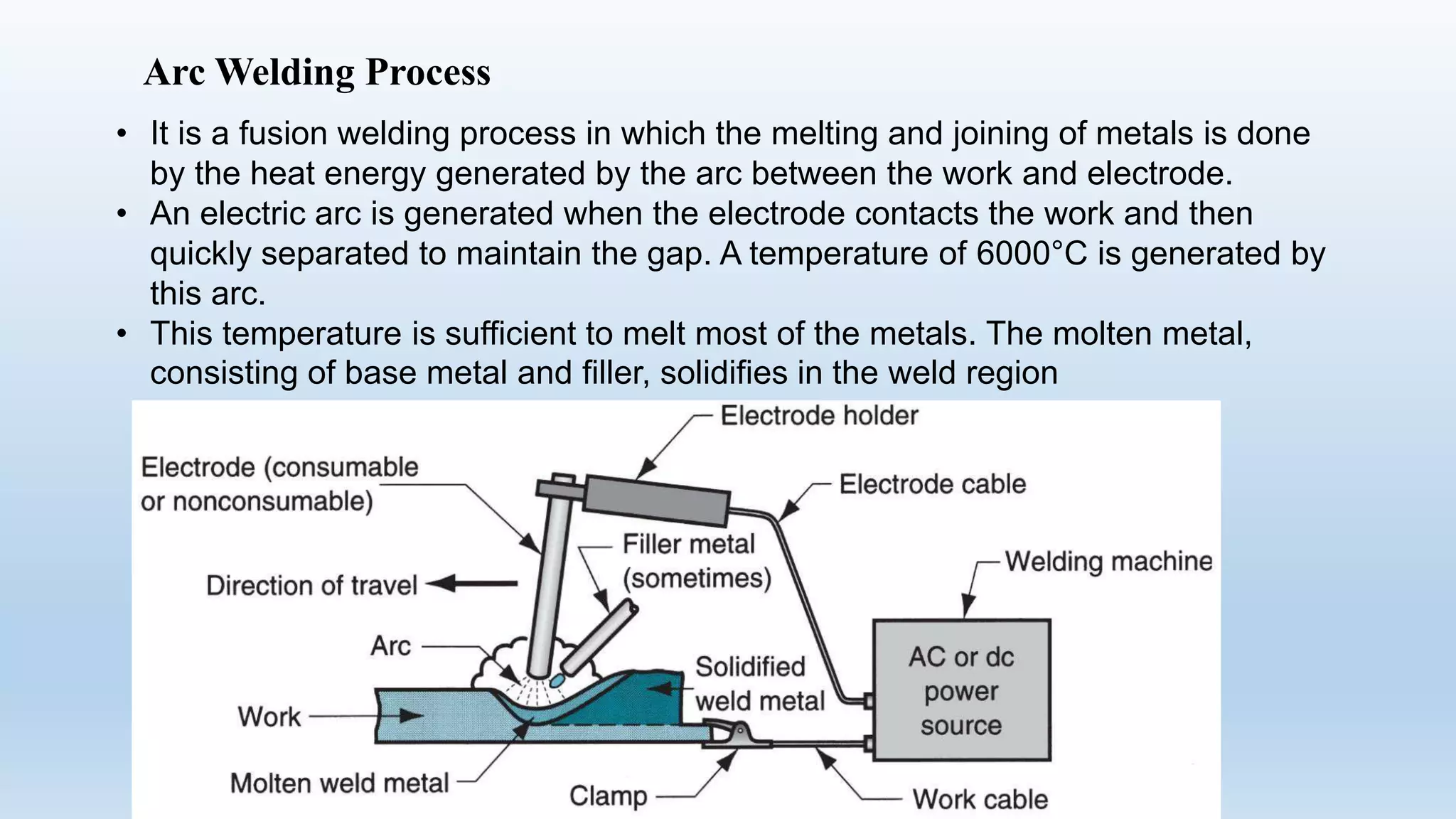

- Welding can involve melting both the filler metal and base metals. Common welding processes discussed are shielded metal arc welding, gas tungsten arc welding, and gas metal arc welding.

- Proper ventilation and safety equipment are important when welding to avoid electrical, fire, explosion, and inhalation hazards.