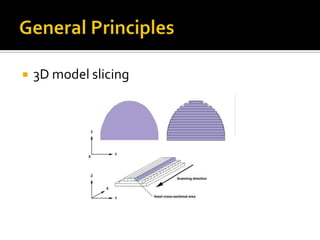

3D printing is an additive manufacturing process where a three-dimensional object is created by laying down successive layers of material under computer control. It builds an object from a digital file describing its shape in thin cross-sections. The 3D printer reads this file and deposits layers of material one by one until the object is completed. Common materials used include plastics, metals, ceramics, and edible substances. 3D printing offers advantages over traditional manufacturing as it enables the creation of complex geometries and customized parts.