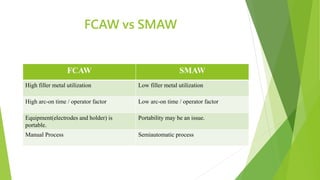

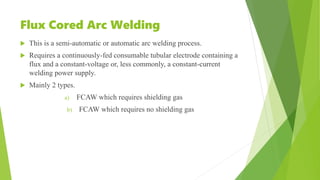

Flux Cored Arc Welding (FCAW), developed in the early 1950s as an alternative to Shielded Metal Arc Welding (SMAW), offers high filler metal utilization and arc-on time. It operates using a continuously-fed tubular electrode, either with or without an external shielding gas, making it suitable for various applications, particularly in controlled environments. However, challenges such as excessive smoke production, operator skill requirements, and equipment mobility issues can impact its usage.