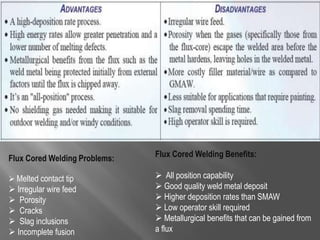

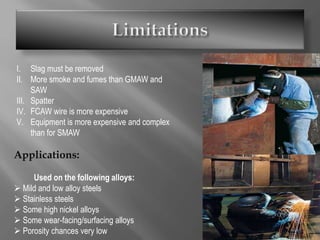

I. The document discusses flux cored arc welding (FCAW) performed by group members Muhammad Saad Baig and Shoaib Ibrahim from the University of the Punjab. It provides details on the FCAW process, equipment used, variables controlled, applications, advantages and limitations compared to other welding processes like SMAW and GMAW.

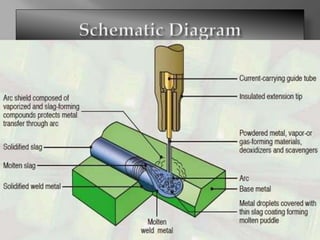

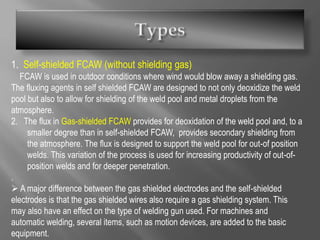

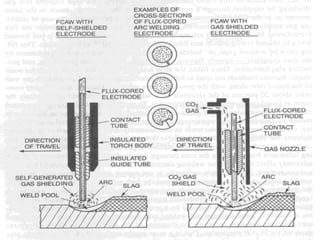

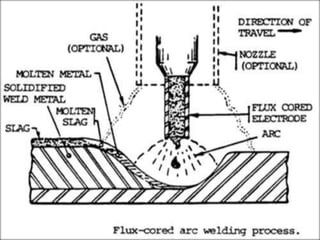

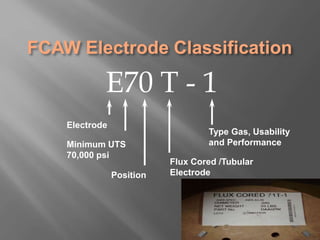

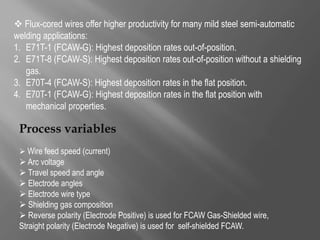

II. FCAW uses a continuously fed consumable tubular electrode containing a flux along with a shielding gas or flux to protect the weld area. It can be performed manually or automatically in all positions and allows for higher deposition rates than SMAW.

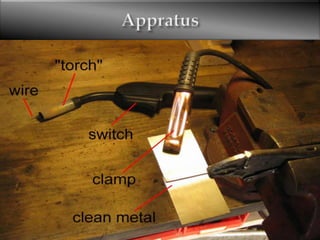

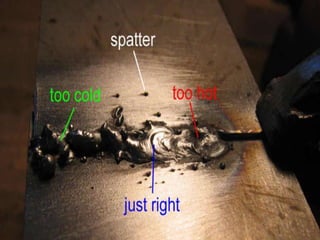

III. The document outlines electrode types used, important process variables and discusses issues like