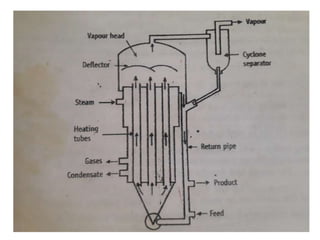

The forced circulation evaporator uses a pump to circulate liquid through steam-jacketed tubes at high pressure, preventing boiling. This superheated liquid exits the tubes into a flash chamber where the sudden pressure drop causes flashing to vapor. A deflector separates the vapor from the concentrated liquid, which returns to the pump for further evaporation. Forced circulation provides efficient heat transfer, separation of phases, and suitability for concentrating thermolabile or high viscosity substances, though the equipment has higher costs due to powering the pump.