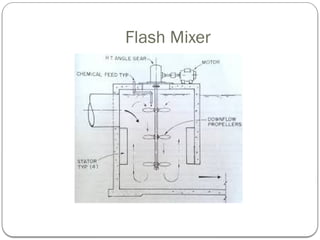

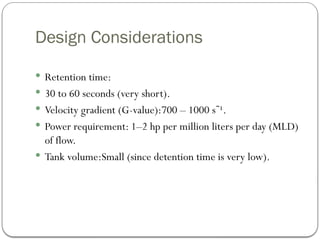

A flash mixer, also known as a rapid mixer, is a mechanical device used in water treatment and other industrial processes to rapidly and uniformly disperse chemicals into a liquid. It's typically the first stage after adding chemicals, designed to ensure thorough mixing before the liquid enters a flocculation basin or other treatment stages.