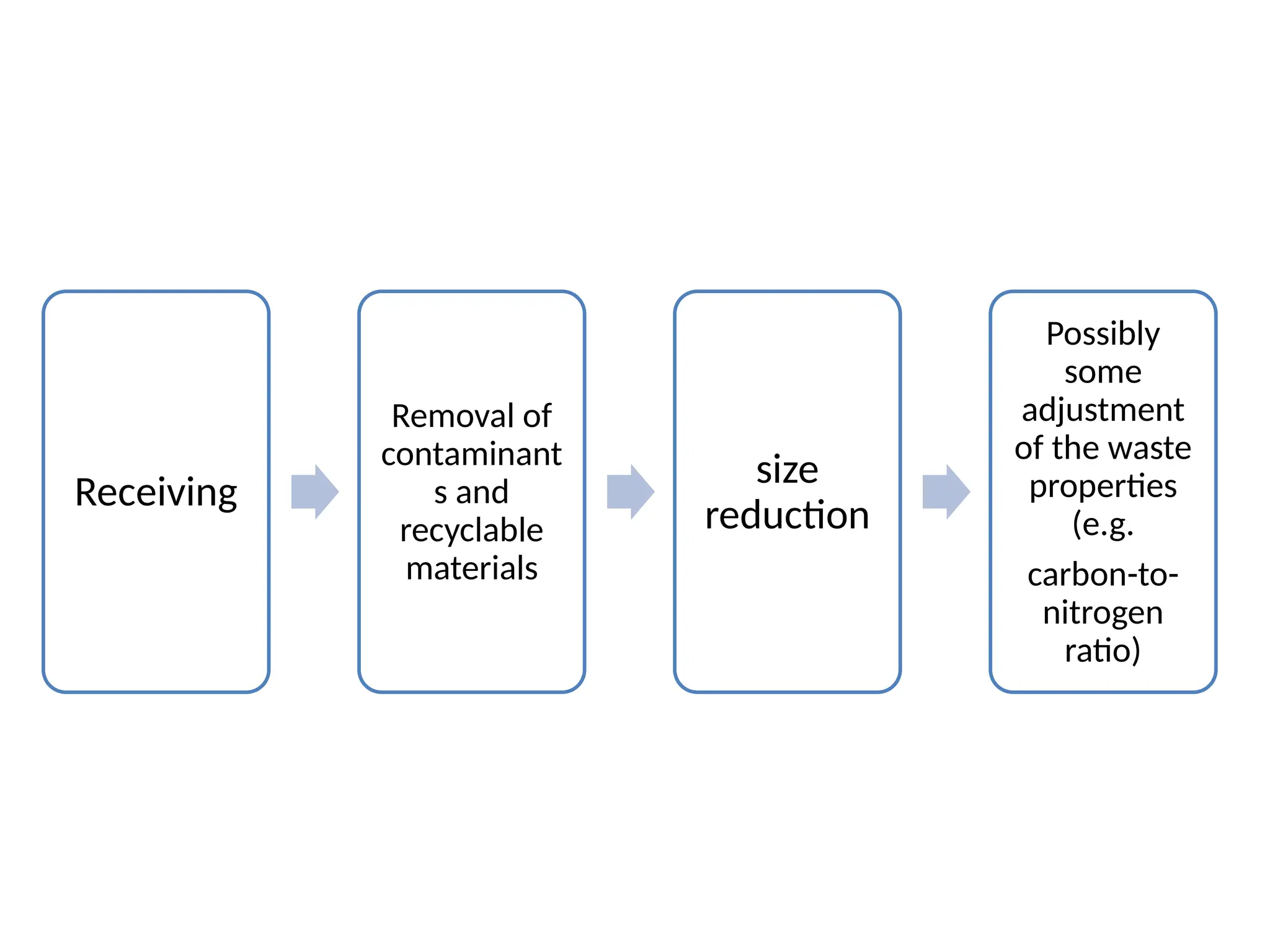

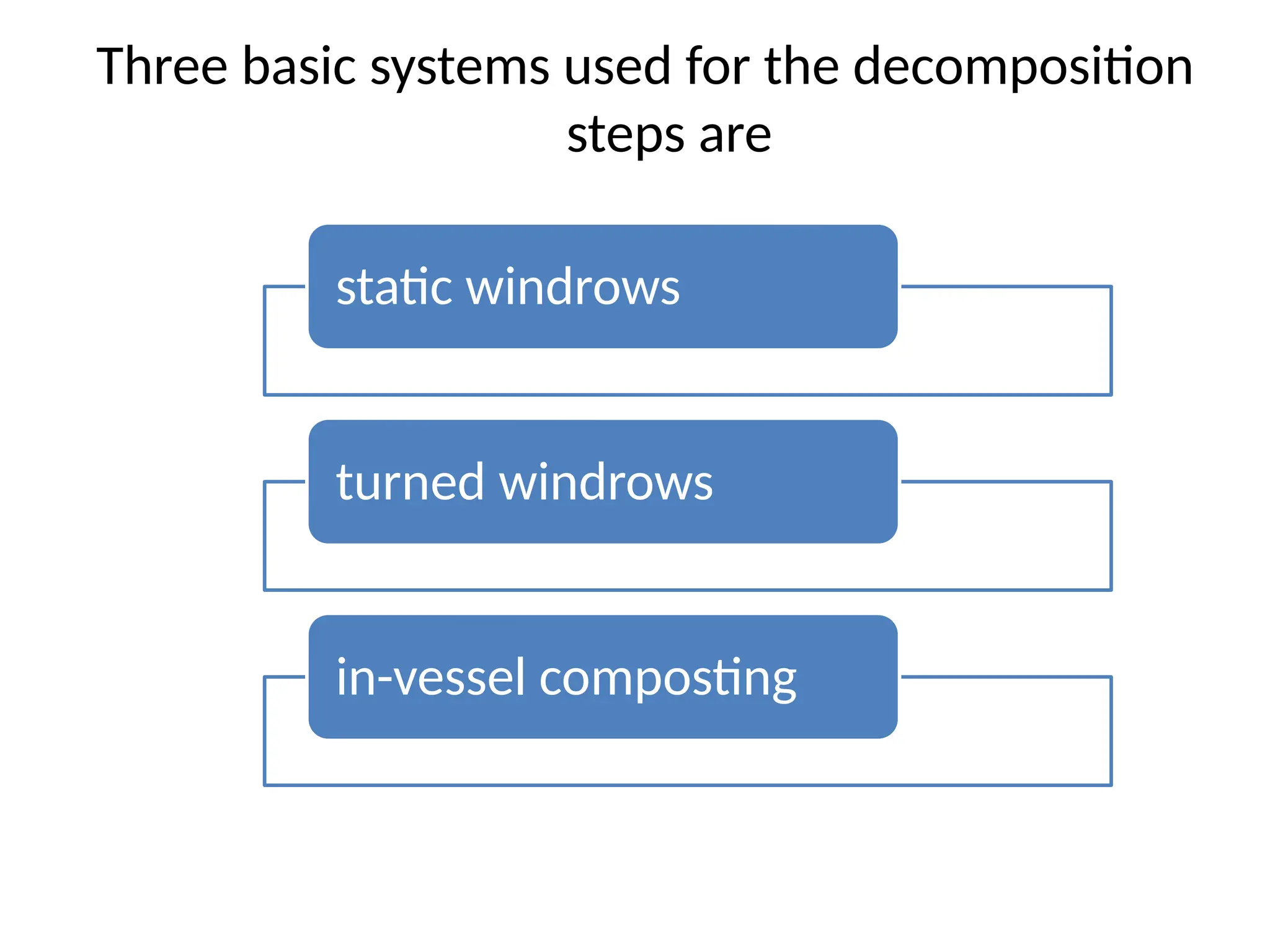

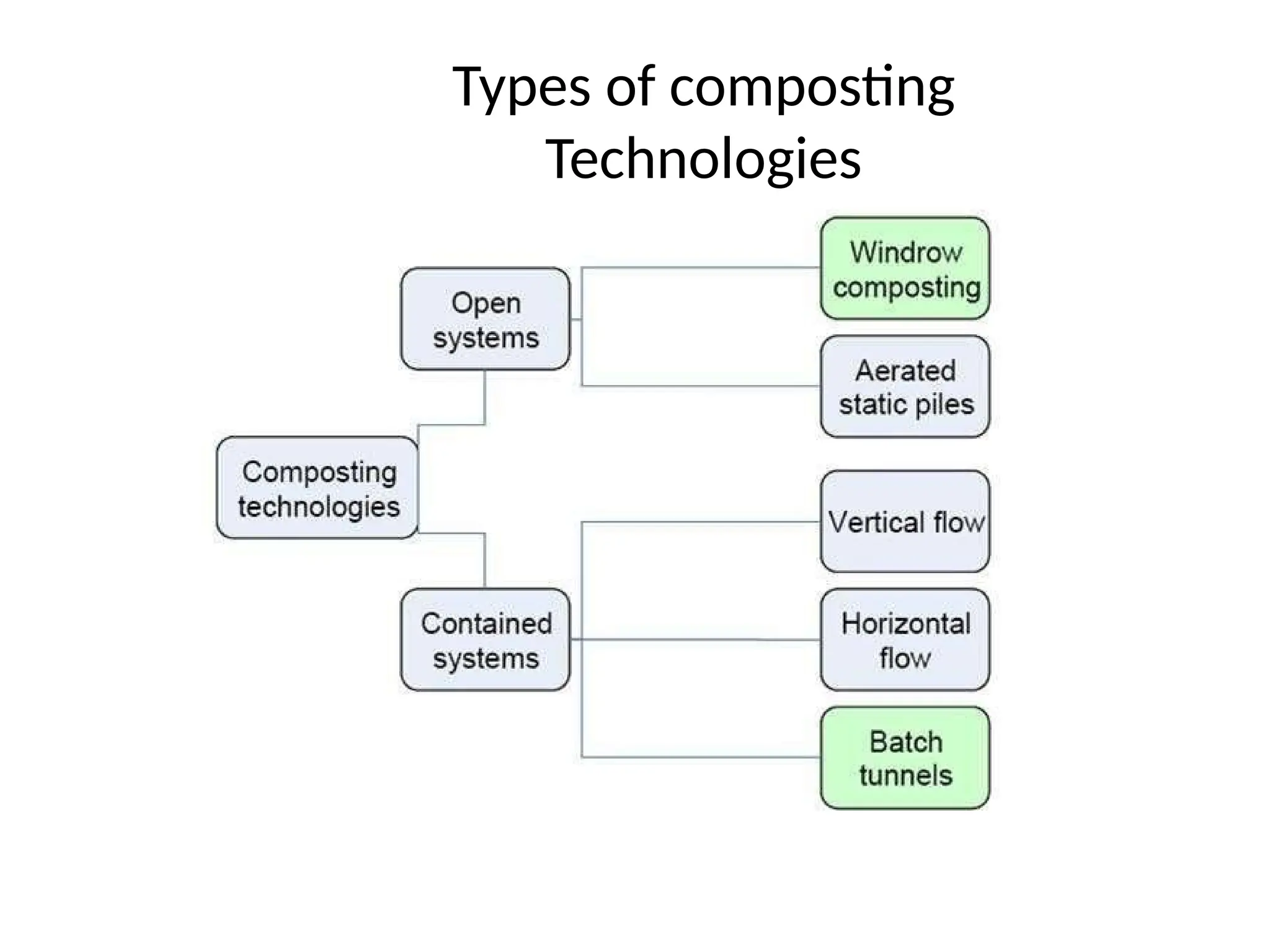

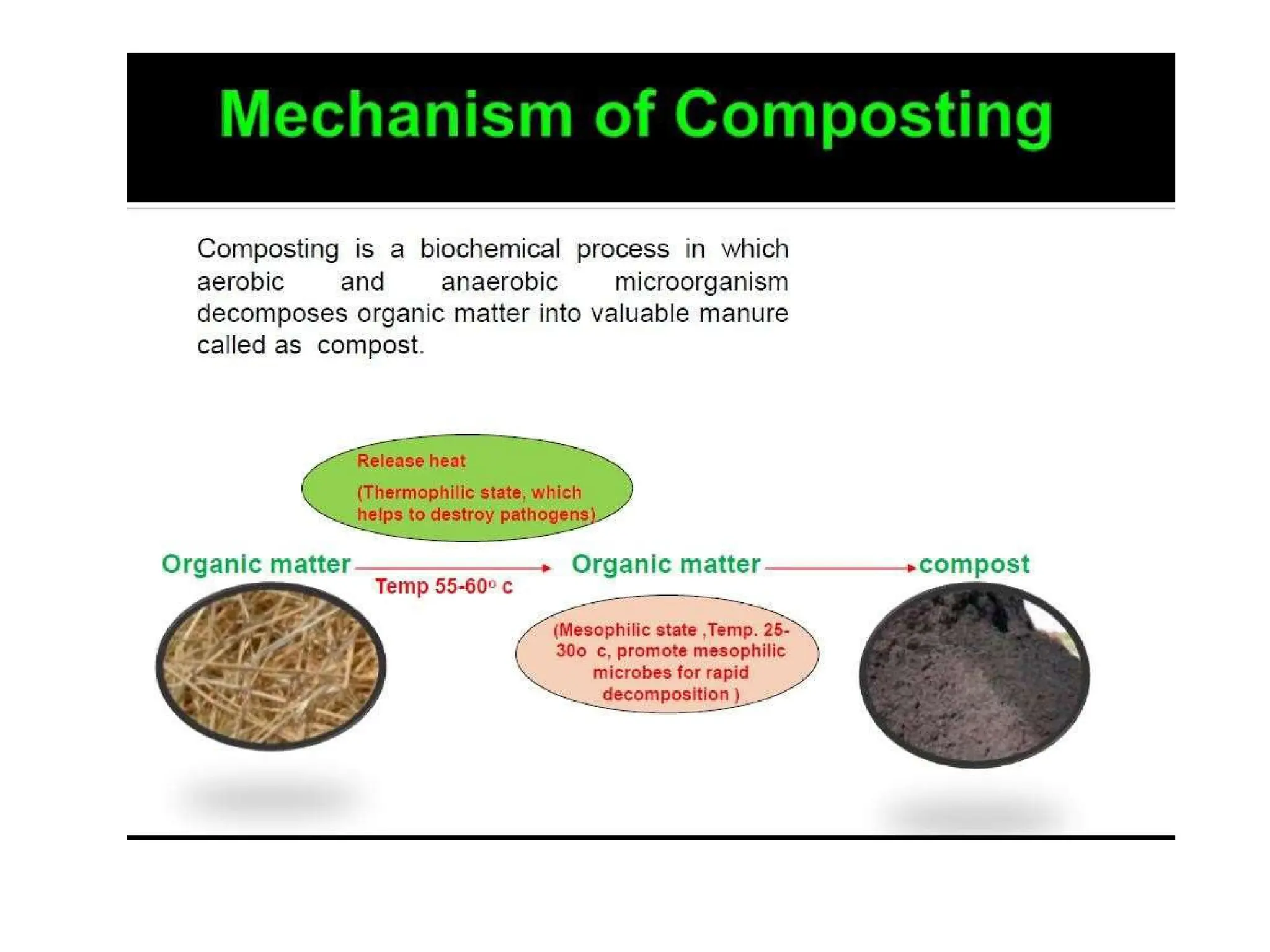

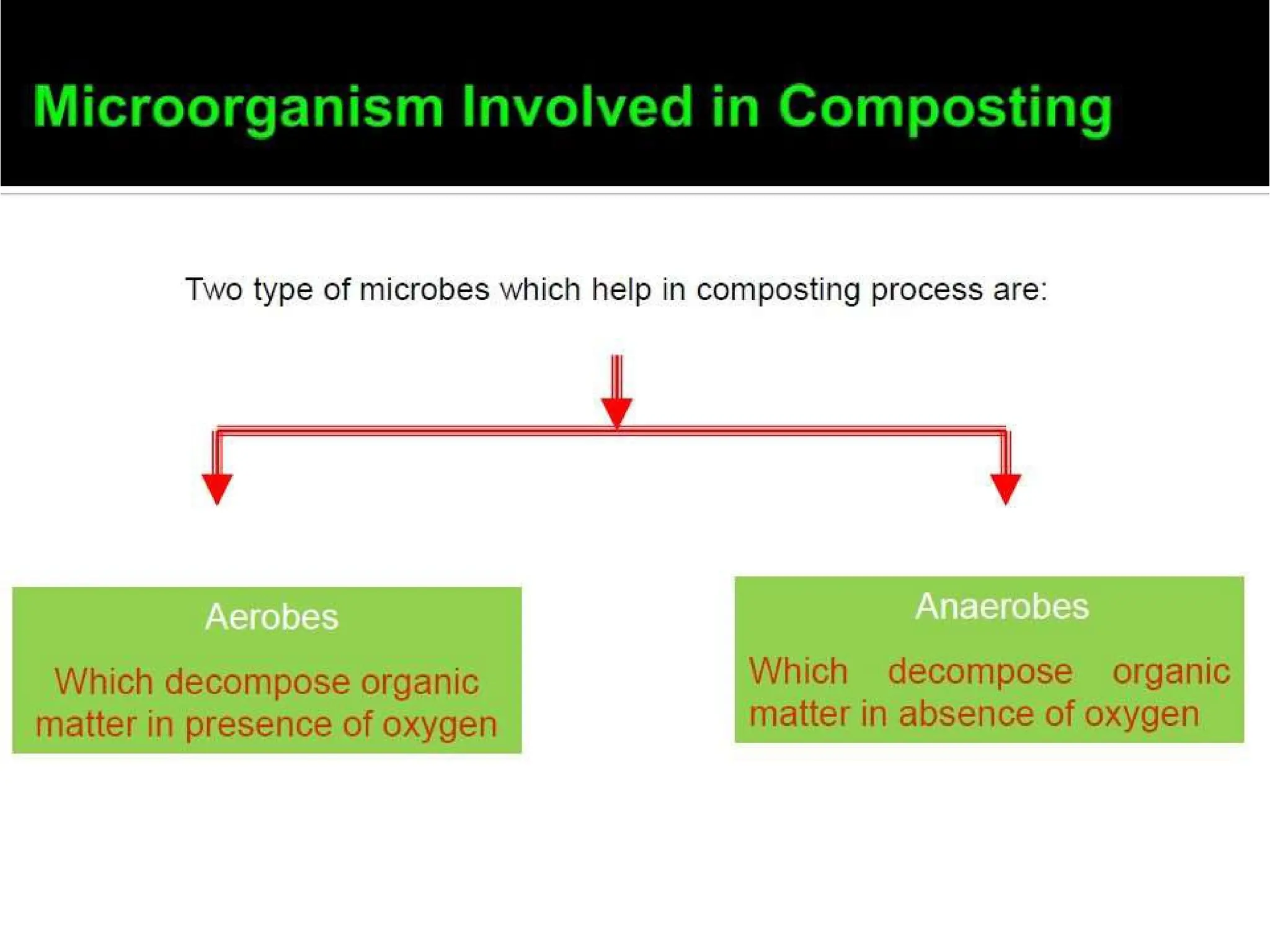

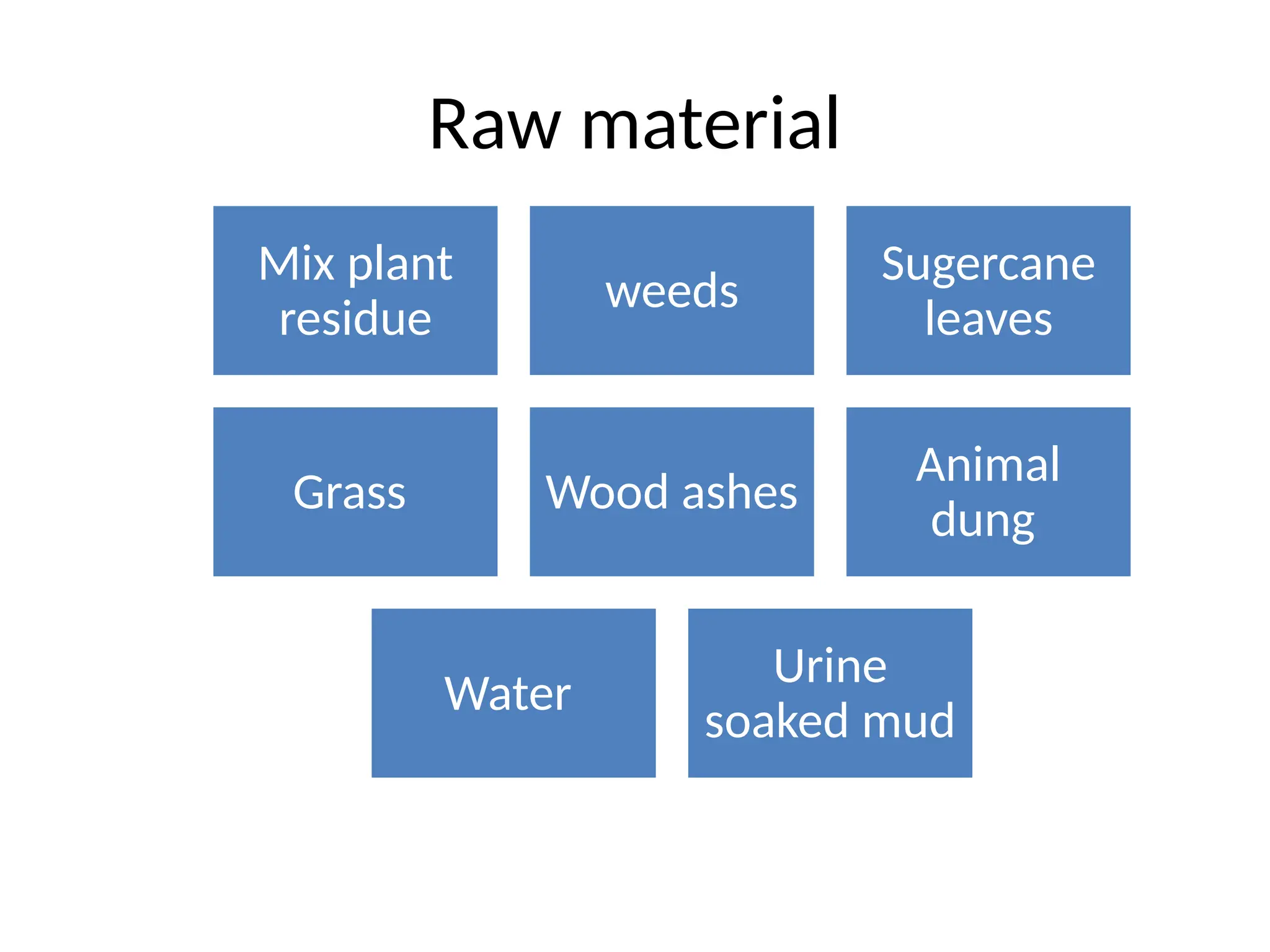

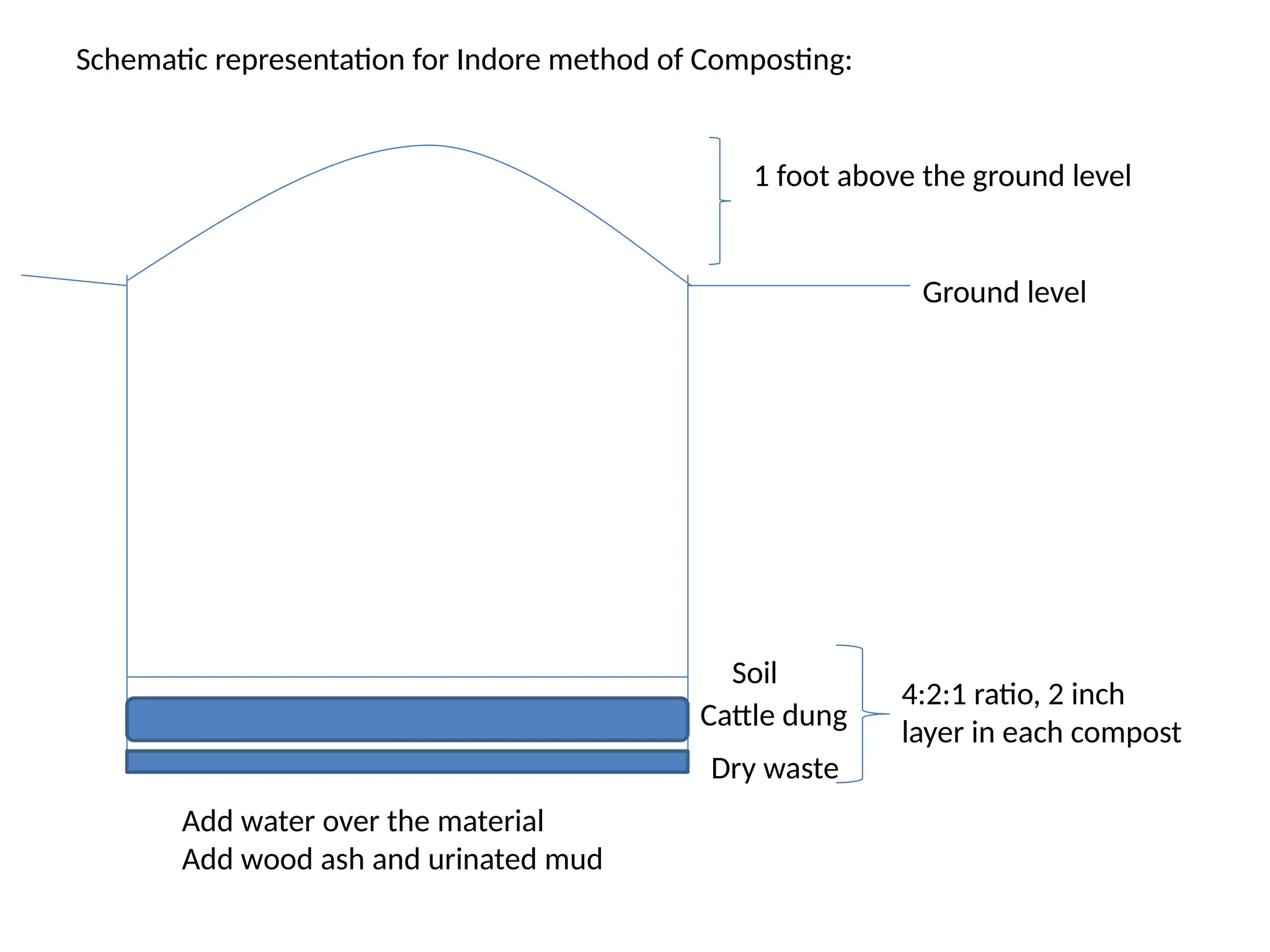

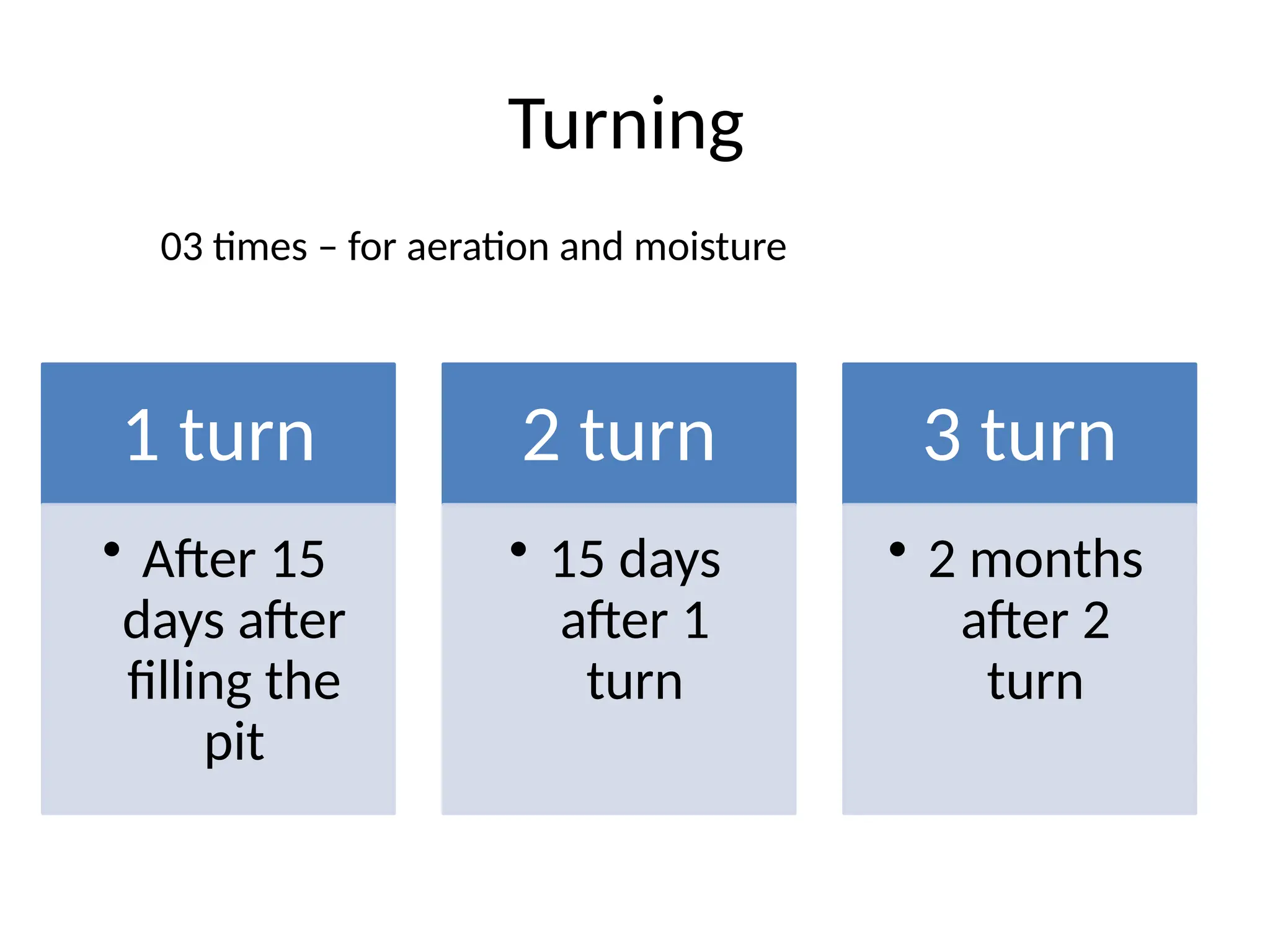

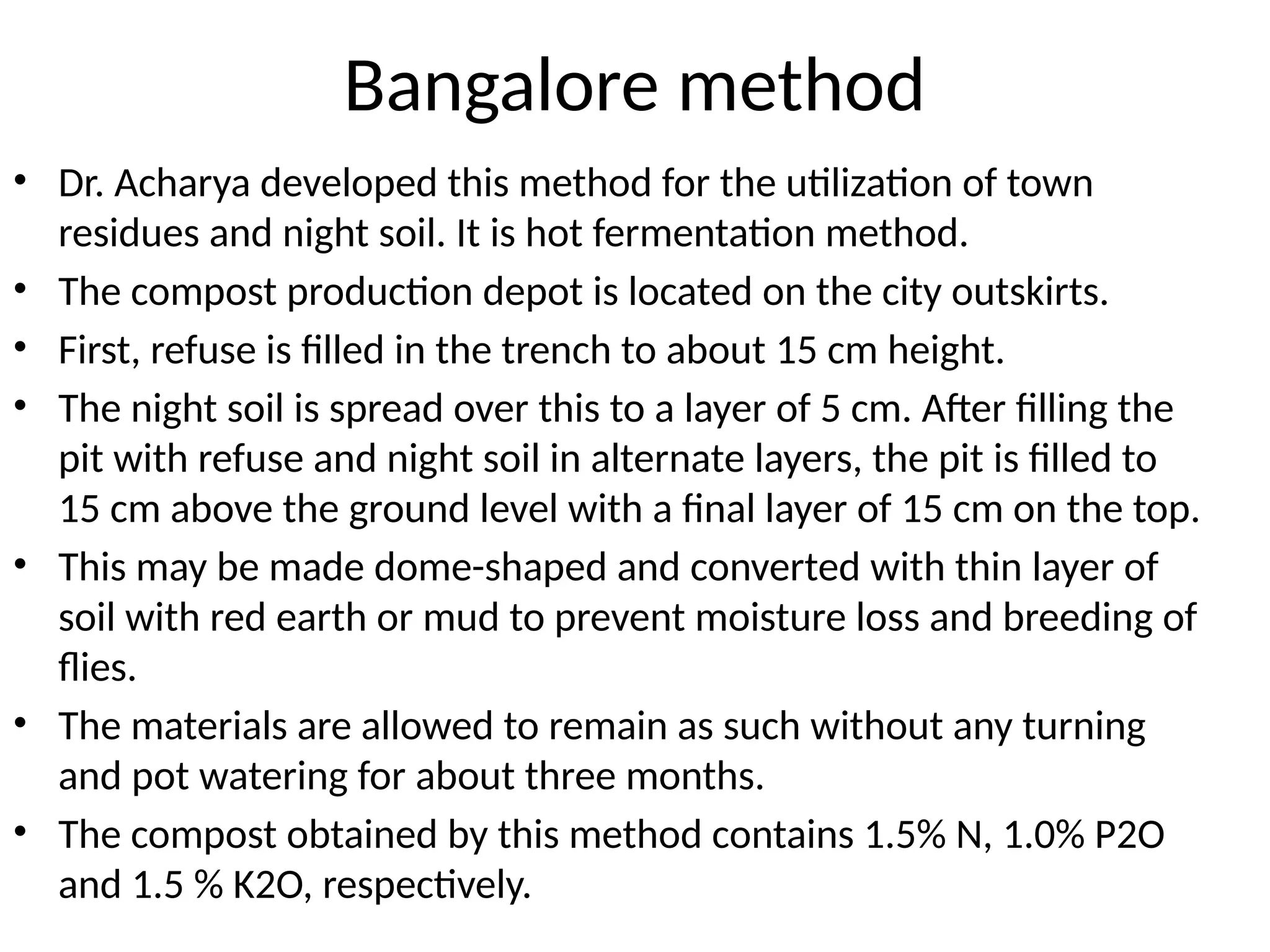

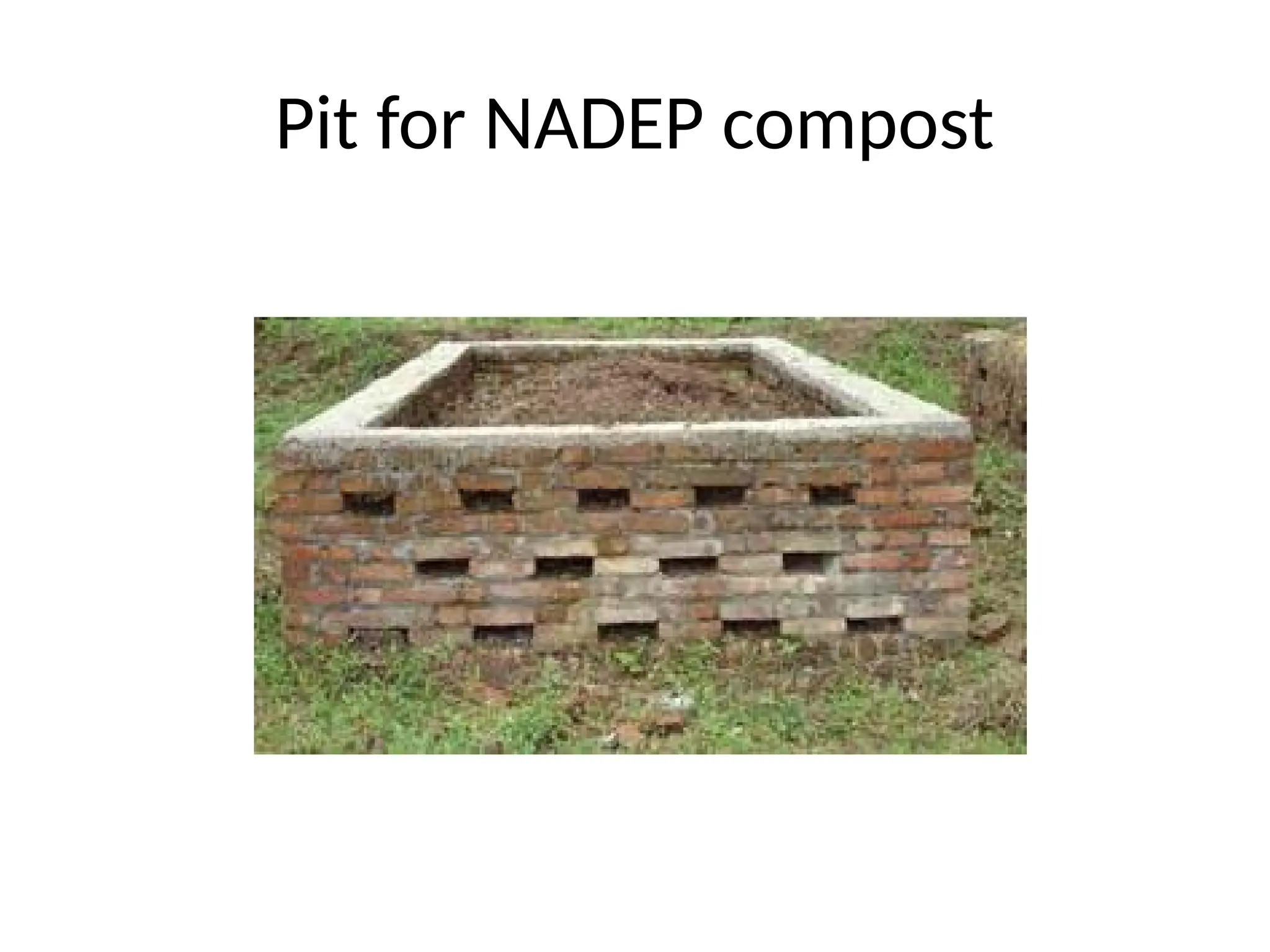

The document discusses composting as a biological process for decomposing organic materials using aerobic microorganisms. It outlines various composting methods, including windrow, in-vessel, and traditional techniques like Nadep and Indore, emphasizing their processes and benefits. Additionally, it highlights compost's environmental advantages, soil enrichment, and the challenges faced in sourcing sufficient compostable materials.