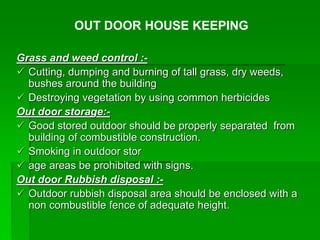

1. Industrial fires can cause casualties, health hazards, property loss, unemployment, and pollution. They require heat, oxygen, and a fuel to start. Good housekeeping, including proper waste storage and maintenance, can prevent fires and their spread.

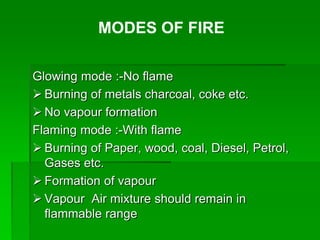

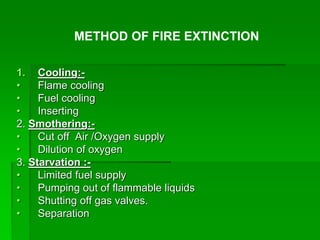

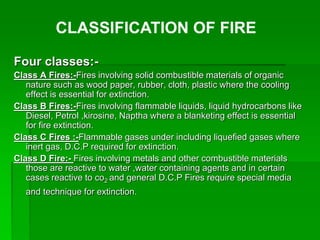

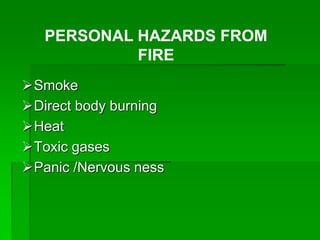

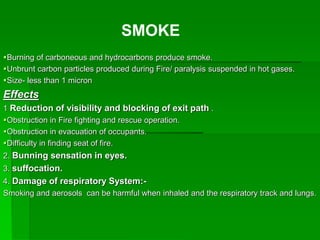

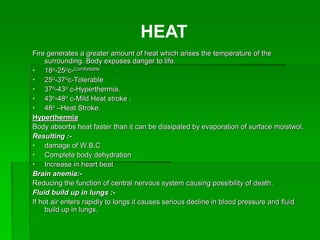

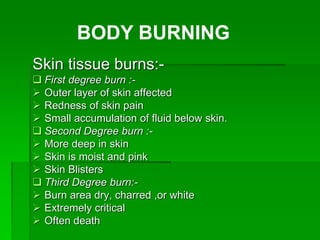

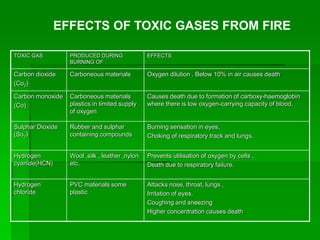

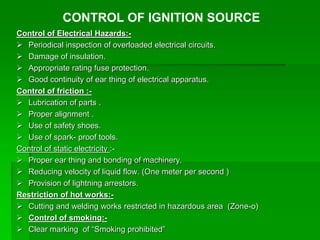

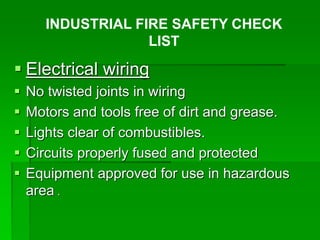

2. There are various fire hazards in industries like electrical faults, welding, hot surfaces, smoking, and spontaneous heating of combustible materials. Fires are classified based on the type of fuel. Extinguishing methods include cooling, starving, or smothering the fire. Toxic gases released during fires can be dangerous.

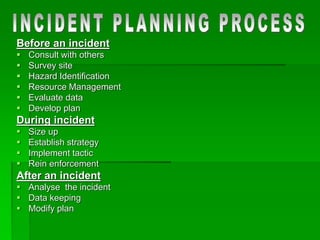

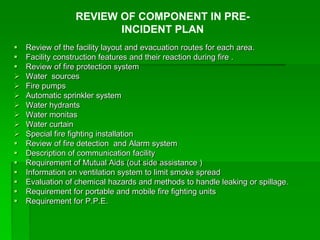

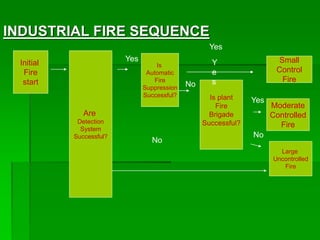

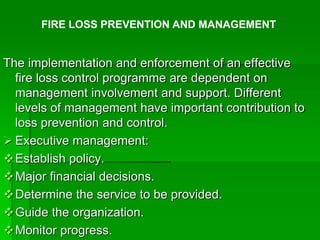

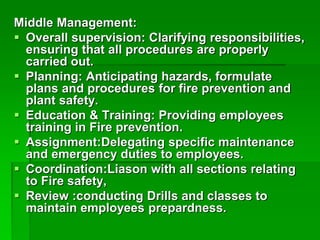

3. Proper management, training, inspections, and pre-incident planning are needed to prevent industrial fires and minimize losses through fire