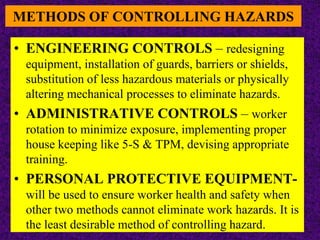

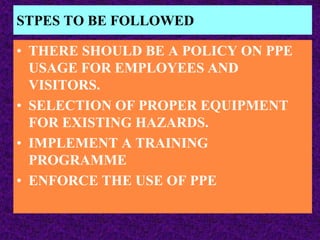

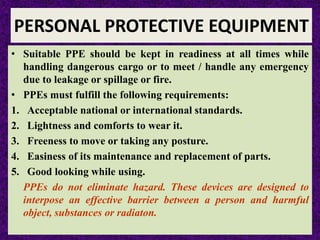

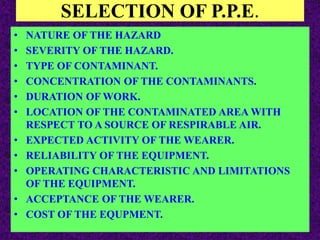

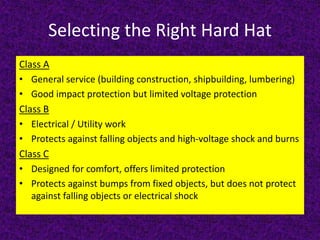

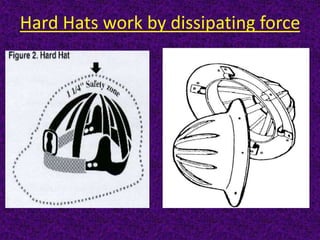

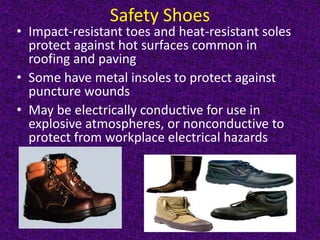

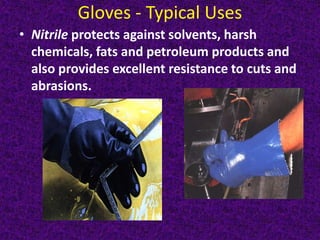

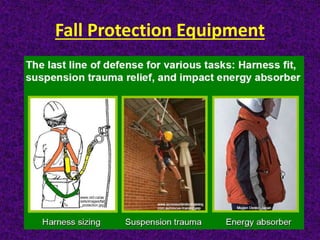

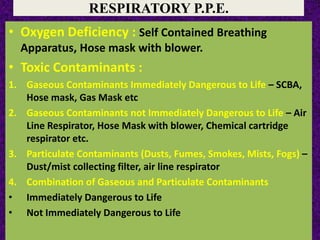

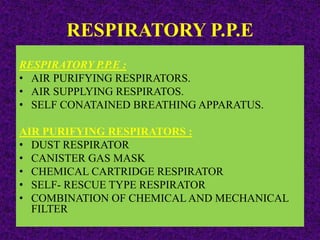

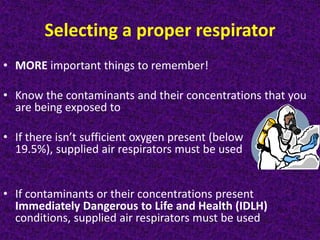

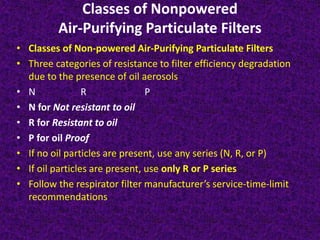

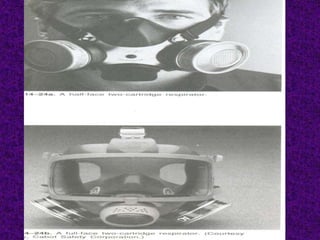

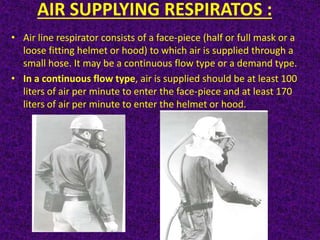

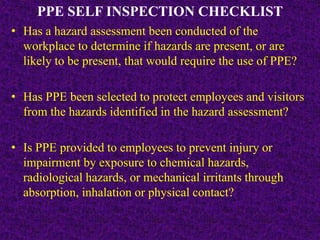

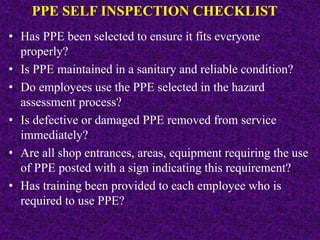

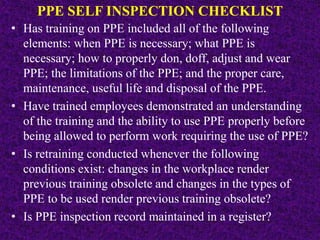

The document discusses personal protective equipment (PPE) and its proper usage. It defines PPE as devices used to protect employees from workplace hazards like chemicals, radiation, physical dangers, and more. The key steps for PPE include conducting a hazard assessment to determine needed PPE, selecting appropriate equipment, training employees on proper use, and enforcing PPE requirements. A variety of PPE types are described, such as hard hats, safety glasses, gloves, fall protection gear, and respiratory equipment.