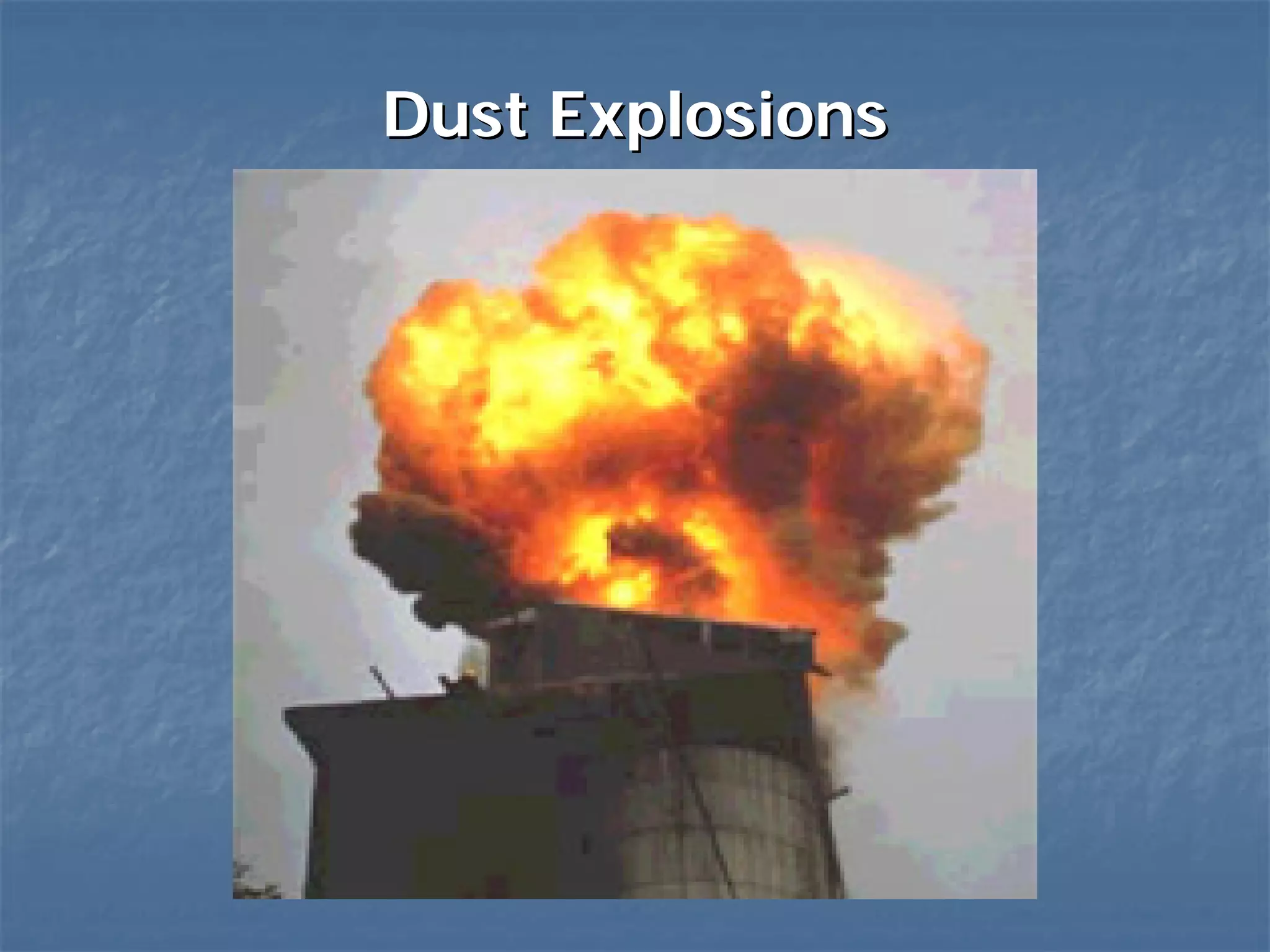

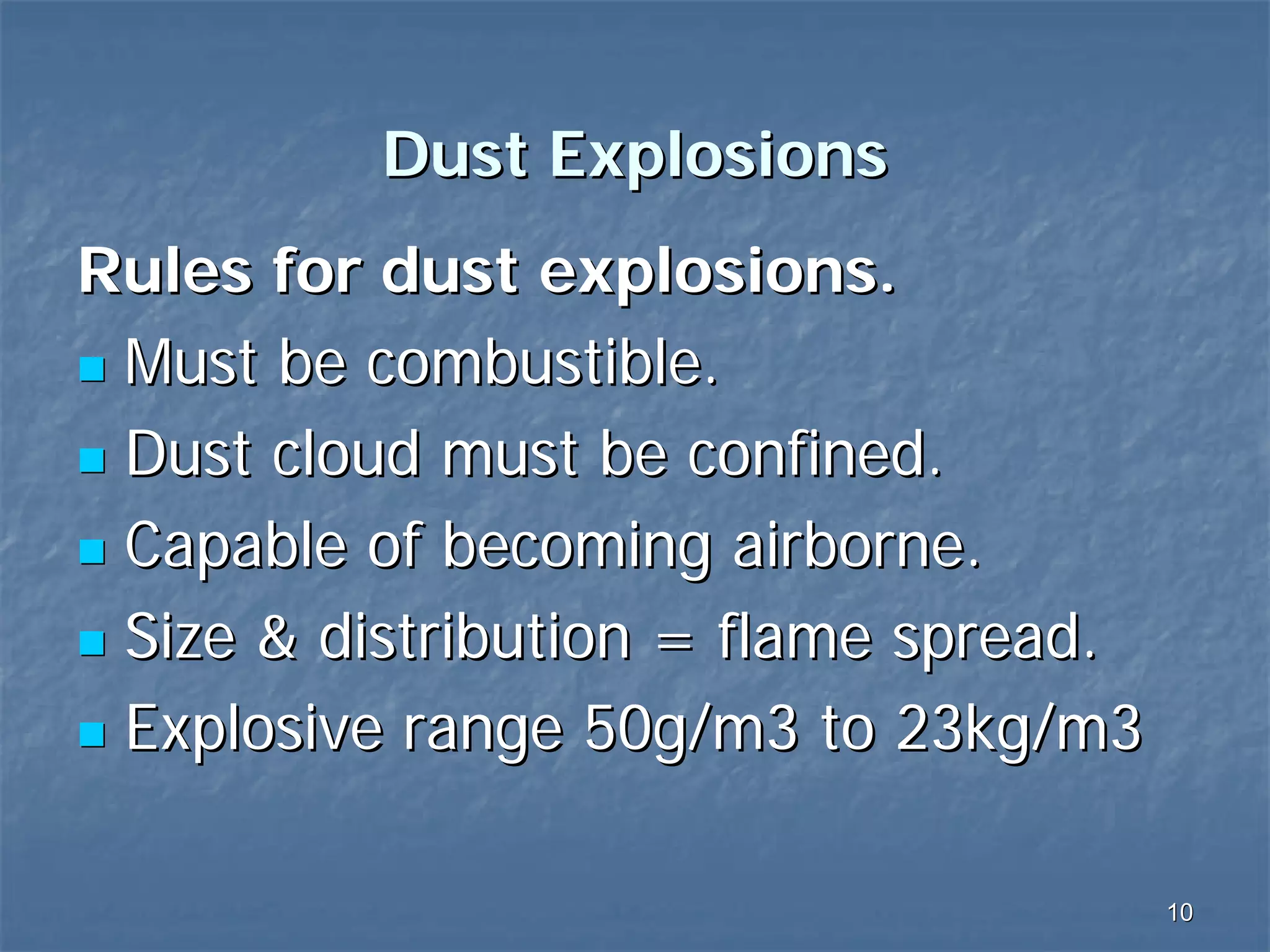

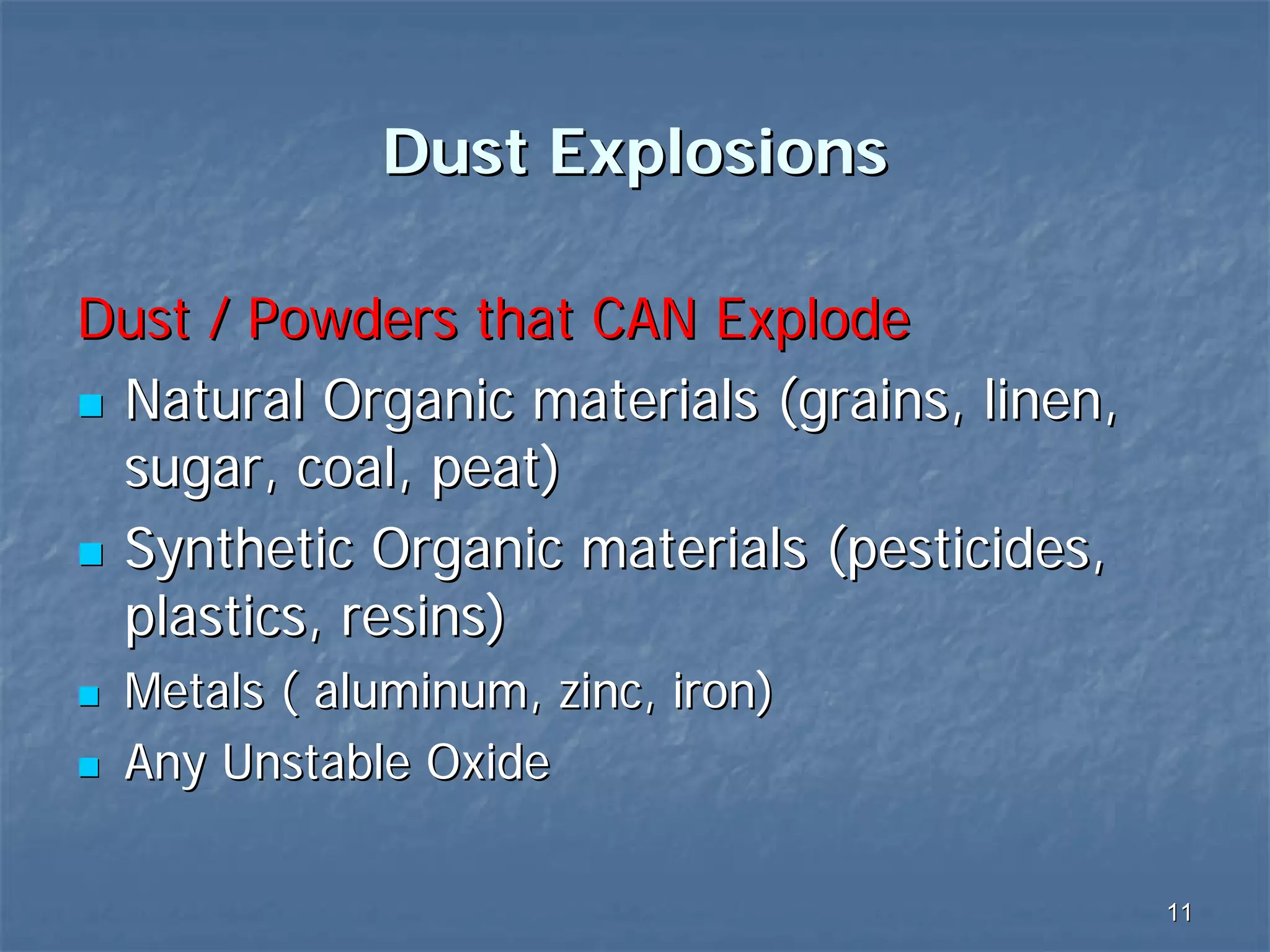

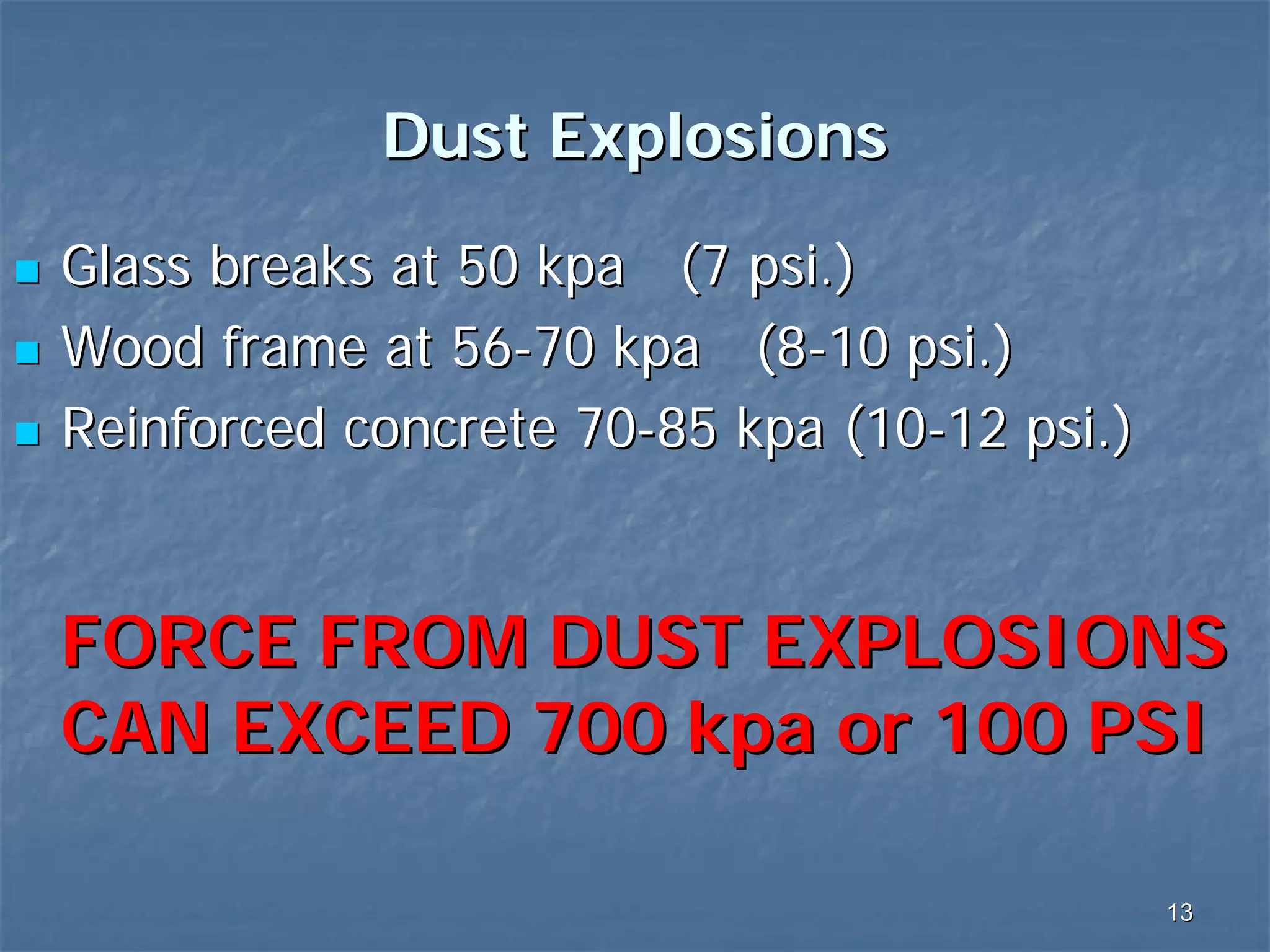

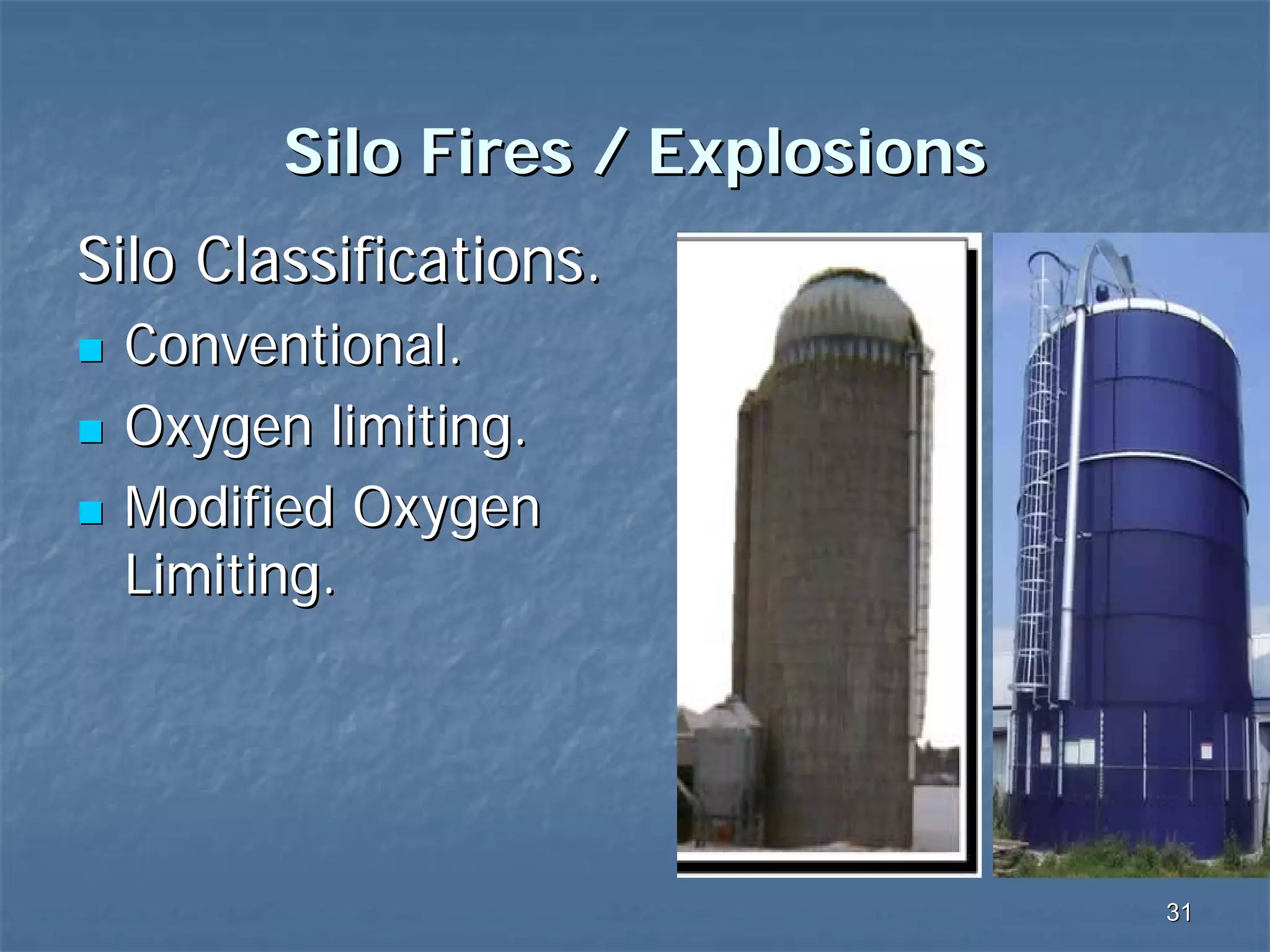

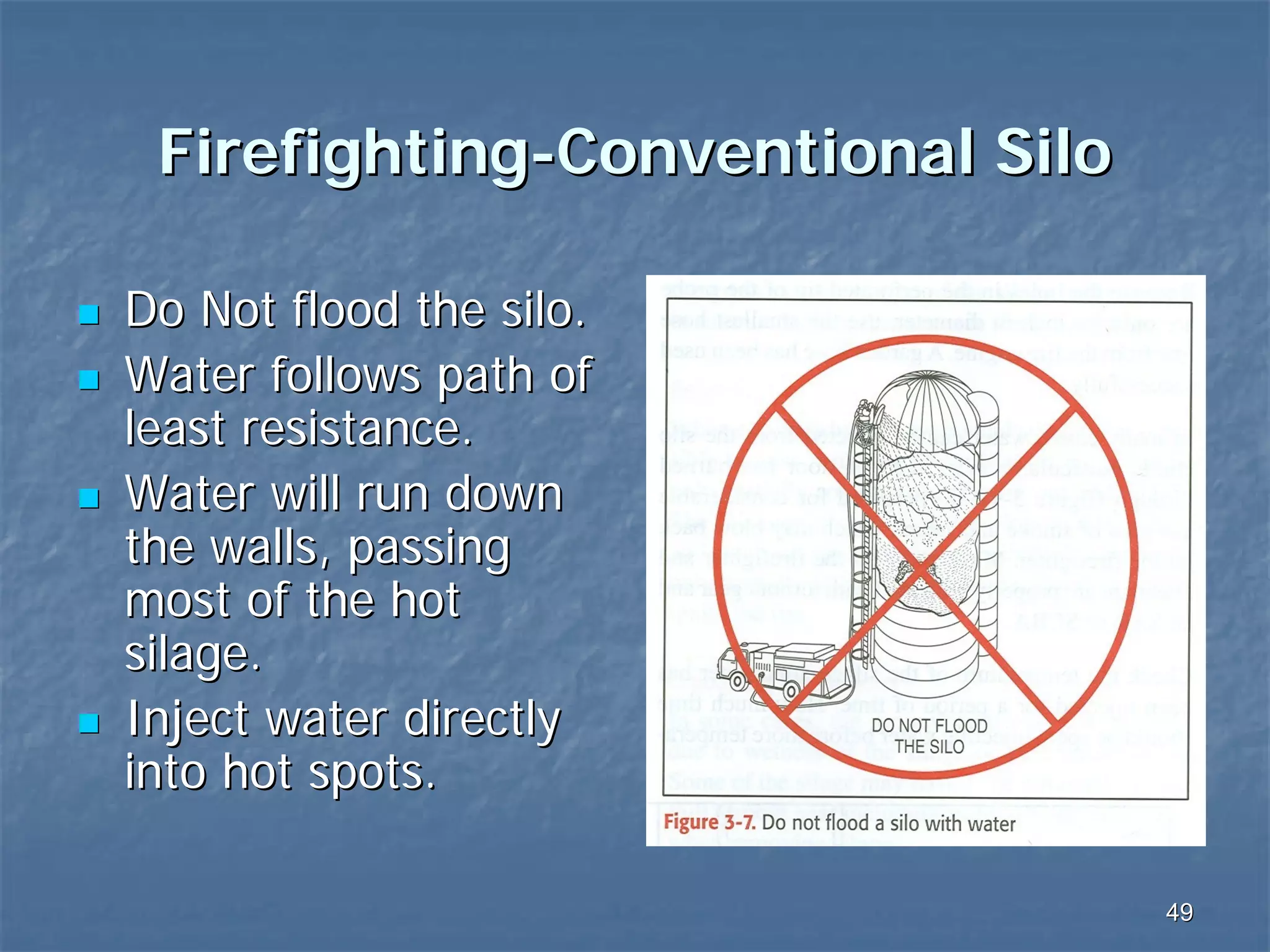

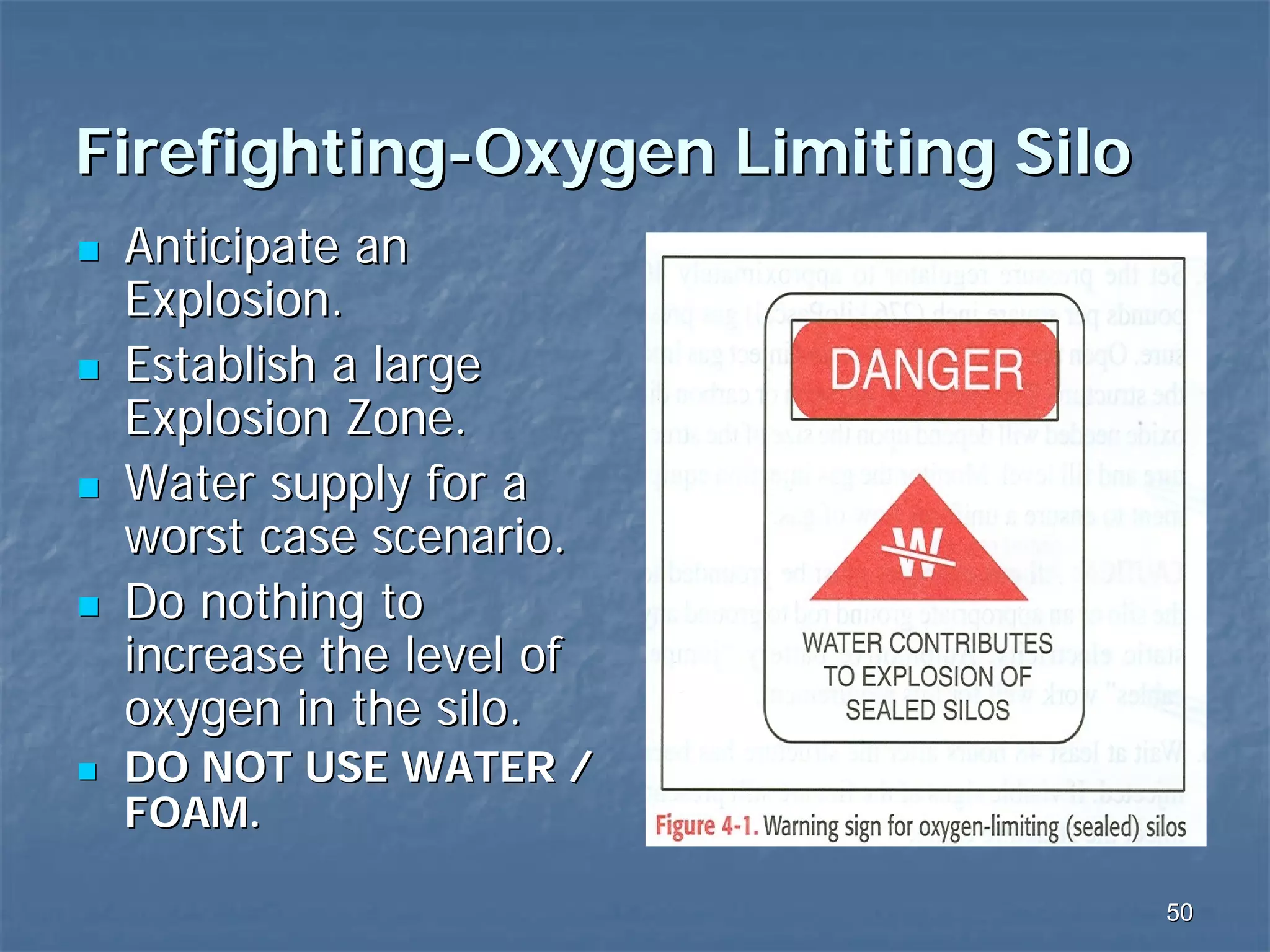

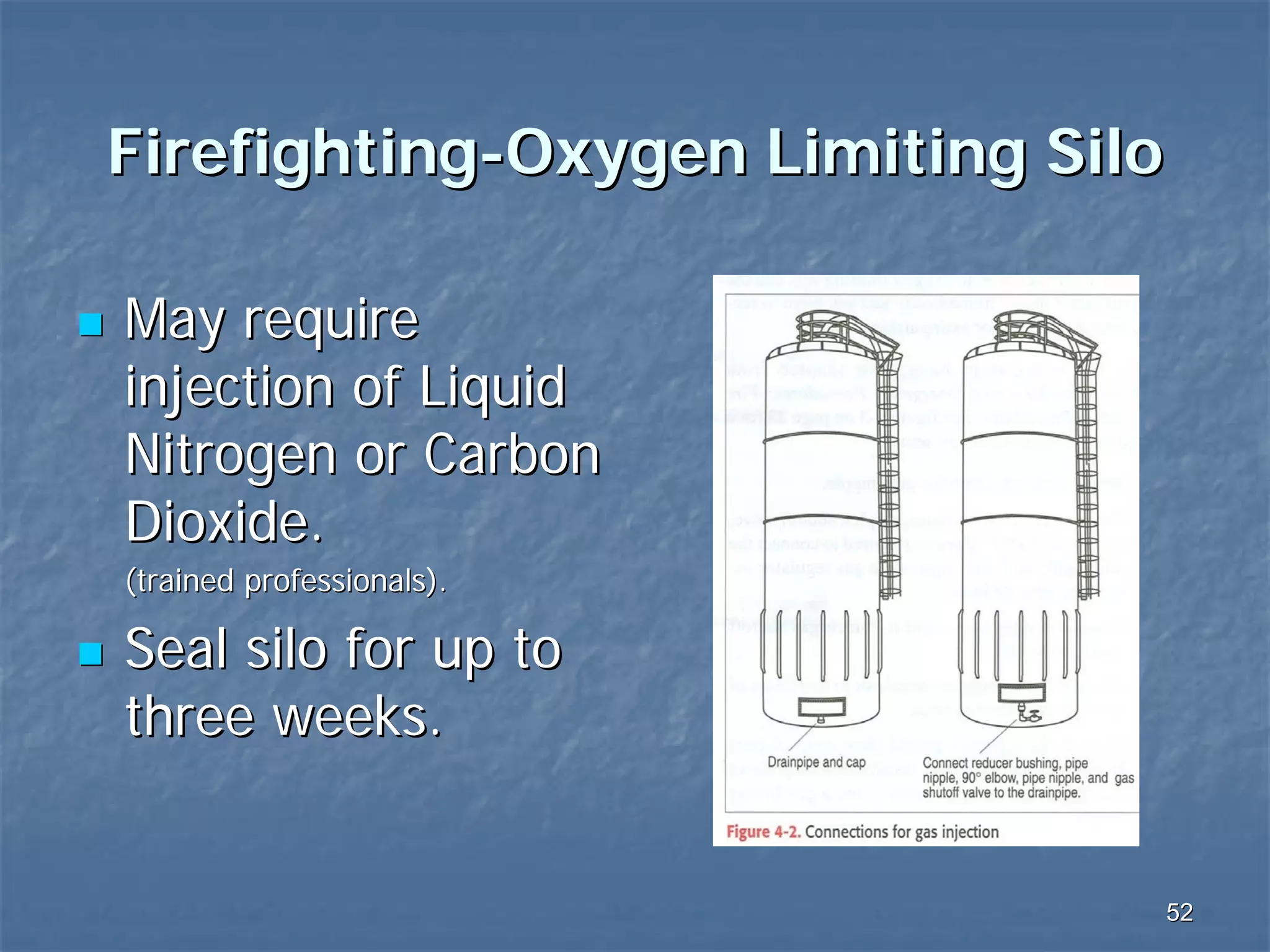

Dust explosions are a significant industrial hazard, with approximately 50 incidents reported annually, leading to numerous fatalities and injuries. A history of various dust explosion events highlights the risks associated with combustible dust from organic and synthetic materials, often causing secondary explosions and widespread damage. Effective firefighting strategies require a thorough understanding of the types of silos and the proper protocols to mitigate the risk of explosions during firefighting operations.