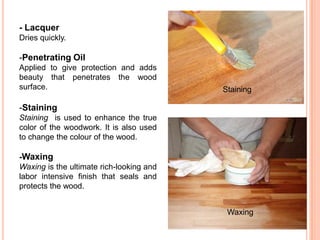

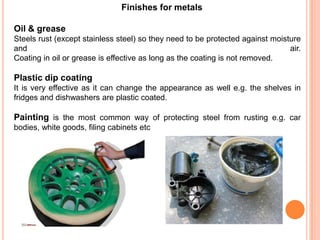

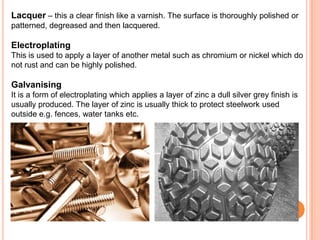

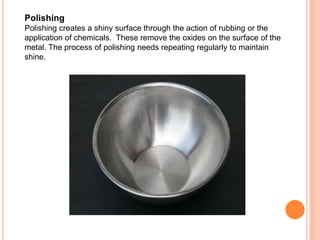

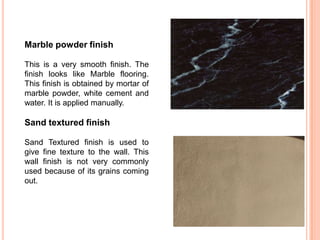

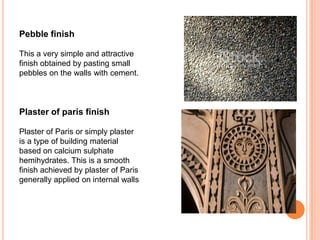

A finish is a coating or layer applied to a material to protect it, change its appearance, or enhance its properties. Different materials require different types of finishes. For wood, common finishes include varnish, lacquer, oil, stain, wax, and dyes, with the type depending on the wood and desired appearance. Metals often require finishes to prevent rust like oil, grease, paint, lacquer, electroplating, galvanizing, or polishing. Wall finishes include wood paneling, laminate, marble powder, sand texture, pebble, and plaster of paris finishes.