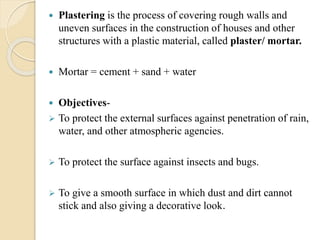

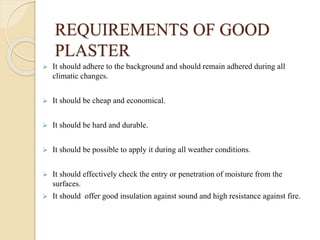

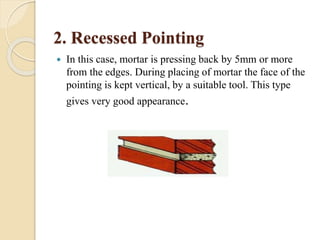

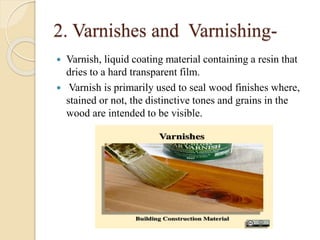

The document outlines basic civil engineering concepts related to building finishes, categorizing them into two groups: Group A, which focuses on protective finishes such as plastering and pointing, and Group B, which emphasizes decorative finishes like paints and varnishes. It details various techniques and materials used in these processes, including specifications for plaster types, painting objectives, and characteristics of good varnishes. Additionally, it covers miscellaneous finishes like wall tiling and wood oiling, highlighting their functions and application methods.