This document discusses xanthan gum, a biopolymer produced through the fermentation of glucose by the bacterium Xanthomonas campestris. It provides information on:

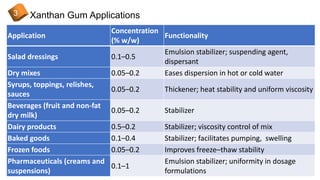

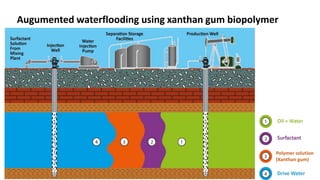

1) Xanthan gum's properties, structure, production process, and applications in foods, cosmetics, and industrial products like drilling fluids and textiles.

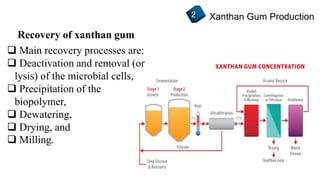

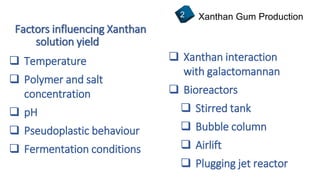

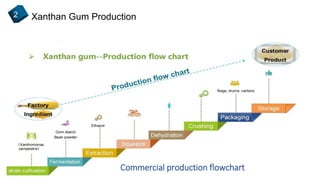

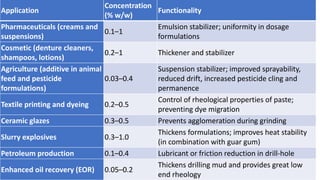

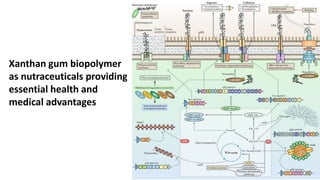

2) How xanthan gum is commercially produced through the fermentation of glucose in a bioreactor, followed by recovery processes to extract and purify the biopolymer.

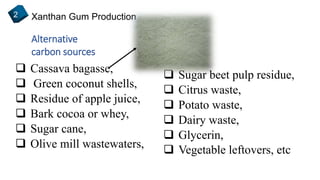

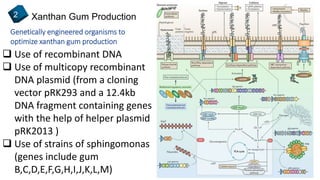

3) Ongoing research seeking to improve xanthan gum production through genetic engineering of bacteria strains and the use of alternative carbon sources for fermentation.

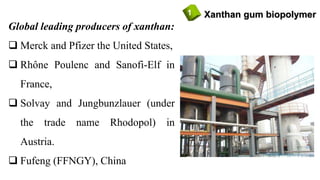

![Xanthan gum biopolymer1

Biopolymers structures

Biopolymers Overview

Chitosan (biopolymer)[1]

[2]](https://image.slidesharecdn.com/xanthangum1-200513010127/85/Xanthan-Gum-Biopolymer-4-320.jpg)

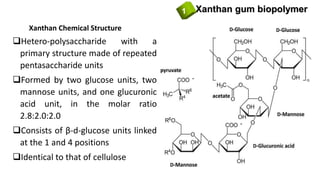

![Xanthan gum biopolymer1

Eco-bacterial polymer granules as biomaterials [2]](https://image.slidesharecdn.com/xanthangum1-200513010127/85/Xanthan-Gum-Biopolymer-5-320.jpg)

![Xanthan gum biopolymer1

Enhanced biopolymers

and biopolymer

synthesis as a target

for drug discovery [2]](https://image.slidesharecdn.com/xanthangum1-200513010127/85/Xanthan-Gum-Biopolymer-6-320.jpg)

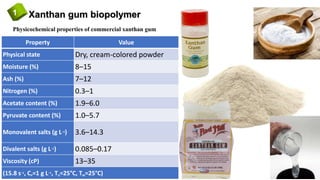

![Xanthan Gum Production2

Xanthomonas cells

occur as single straight

rods, 0.4–0.7μm wide

and 0.7–1.8 μm long.

The cells are motile,

Gram-negative, and

they have a single polar

flagellum (1.7–3 μm

long)

Bacteria D-Glucose

D-

Mannose

D-Glucuronic

acid

Pyruvate Acetate

X. campestris 30.1 27.3 14.9 7.1 6.5

X. fragaria 1822 24.6 26.1 14.0 4.9 5.5

X.

gummisudans 21

82

34.8 30.7 16.5 4.7 10.0

X. juglandis 411 33.2 30.2 16.8 6.9 6.4

X. phaseoli 1128 30.9 28.6 15.3 1.8 6.4

X.

vasculorum 702

34.9 30.2 17.9 6.6 6.3

Microorganism

Mean %composition of polysaccharides by Xanthomonas

bacteria [3]](https://image.slidesharecdn.com/xanthangum1-200513010127/85/Xanthan-Gum-Biopolymer-13-320.jpg)

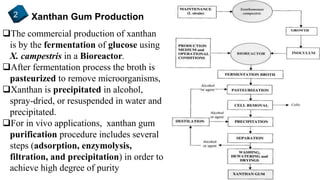

![Xanthan Gum Production2

Genetic engineered

Xanthan bacteria

pathway[4]](https://image.slidesharecdn.com/xanthangum1-200513010127/85/Xanthan-Gum-Biopolymer-15-320.jpg)

![Xanthan Gum Production2

Growth medium/nutrient[5]

S/NO Medium Ranged used (g.l-1) S/NO Medium Ranged used (g.l-1)

1 Glucose 10-42 13 CaCO3 0.020-20

2 Saccharose 1.125-50 14 CaCl2.2H2O 0.002

3 CH4N2O 0.10 15 Malt extract 3

4 Citric acid 2.0-2.1 16 Yeast extract 3-10

5 NH4NO3 0.217-1.144 17 Peptone 0.34

6 KH2PO4 1.0-5.0 18 Tryptone 10

7 MgSO4.7H2O 0.25-20 19 Soybean flour 15

8 NH4Cl 1.94 20 HCl 0.13-0.16

9 H3BO3 0.006 21 MgCl2 0.507

10 Na2HPO4 0.089 22 ZnO 0.006

11 ZnSO4 0.002 23 (NH4)2HPO4 0.217-1.5

12 FeCl3.6H2O 0.0042-0.024 24 MgSO4.7H2O 0.25-0.3](https://image.slidesharecdn.com/xanthangum1-200513010127/85/Xanthan-Gum-Biopolymer-17-320.jpg)