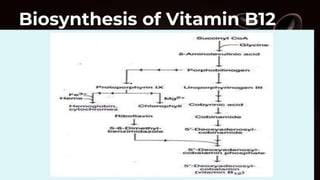

Vitamin B12, a cobalamin compound with a cobalt atom at its core, is produced on a commercial scale using microbes like Pseudomonas denitrificans and Propionibacterium species due to their rapid growth and productivity. The production process involves selection of microorganisms, formulation of a nutrient-rich medium, and two phases of fermentation (anaerobic and aerobic) to synthesize cobalamin. Vitamin B12 is essential for red blood cell formation, reducing birth defects, supporting bone health, and improving mood and heart health.