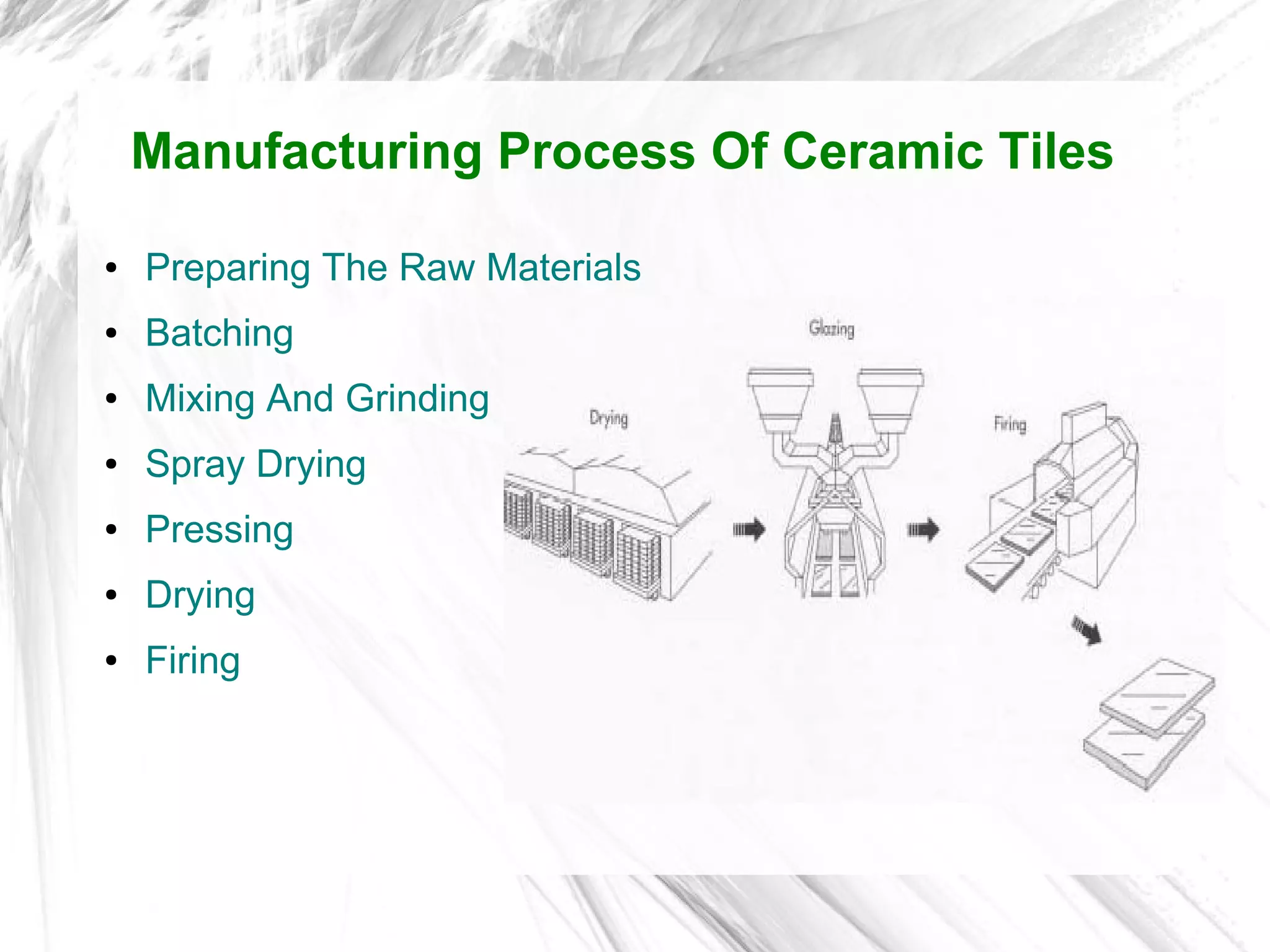

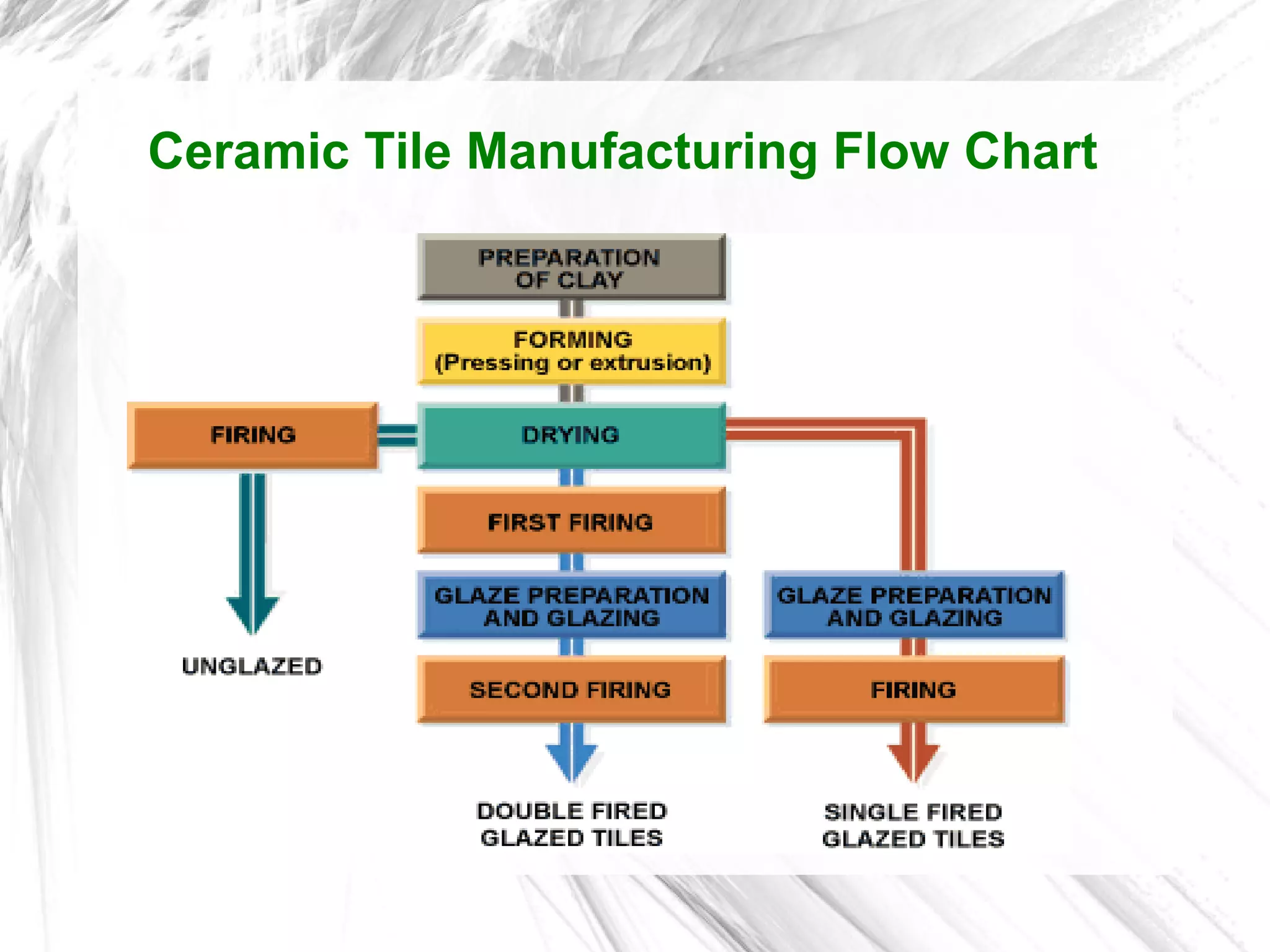

The document outlines the 7-step manufacturing process for ceramic tiles:

1) Preparing raw materials like clay and feldspar.

2) Batching involves proportioning raw materials by mass for accuracy.

3) Mixing and grinding reduces raw materials to a uniform size.

4) Spray drying converts the body slip to granules suitable for pressing.

5) Pressing simultaneously compacts and shapes the granules in rigid dies.

6) Drying increases strength before firing and prevents warping in the kiln.

7) Firing at high temperatures transforms the shaped granules into durable ceramic tiles.