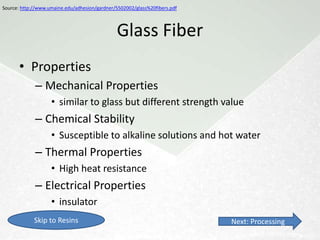

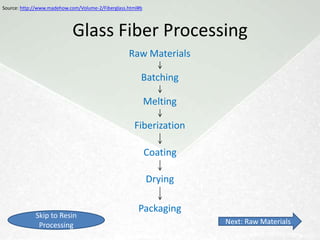

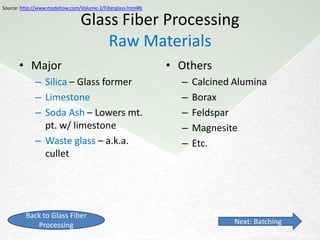

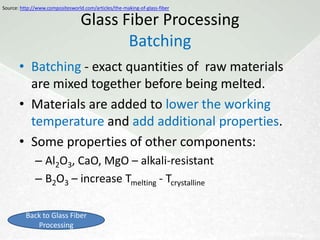

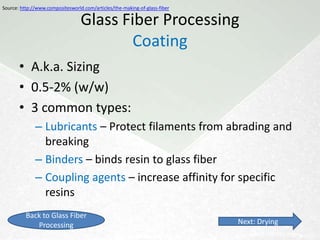

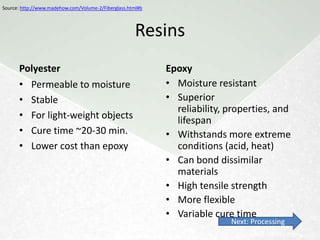

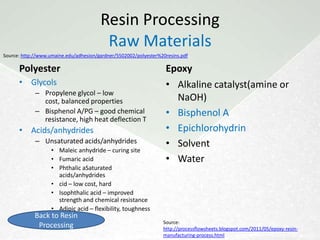

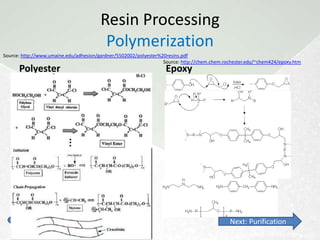

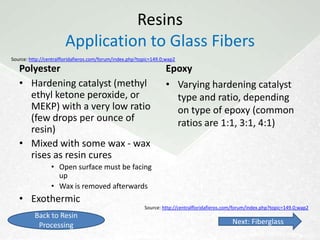

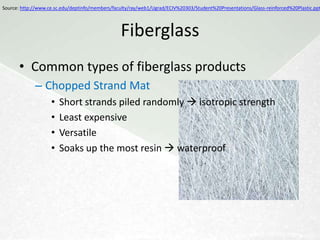

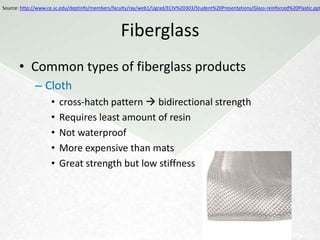

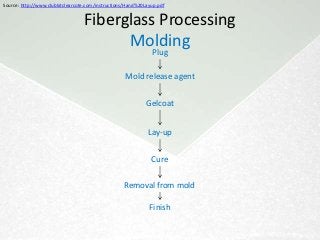

Fiberglass is a composite material made of glass fibers set in a plastic resin matrix. Glass fibers have high tensile strength but are weak in shear. Common resins used are polyester, epoxy, and vinyl ester. Fiberglass is produced by drawing glass into fine fibers, coating them, and combining the fibers with resin. It is used in many applications due to its high strength to weight ratio and resistance to corrosion.