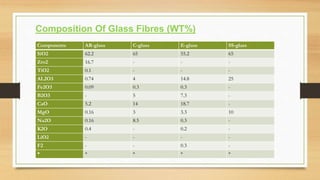

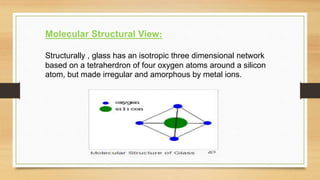

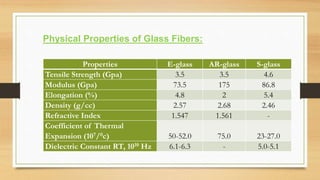

Glass fiber is a material consisting of extremely fine glass fibers. It is produced through a two-stage process - glass manufacture involving melting raw materials and fiber drawing where the melt is passed through bushings to produce continuous fibers. There are different types of glass fibers based on their composition, including soda-lime, borosilicate, and quartz fibers. Glass fiber has properties like high tensile strength, electrical insulation, and heat and corrosion resistance, making it useful for applications such as thermal and sound insulation, reinforcement of materials, and FRP tanks.