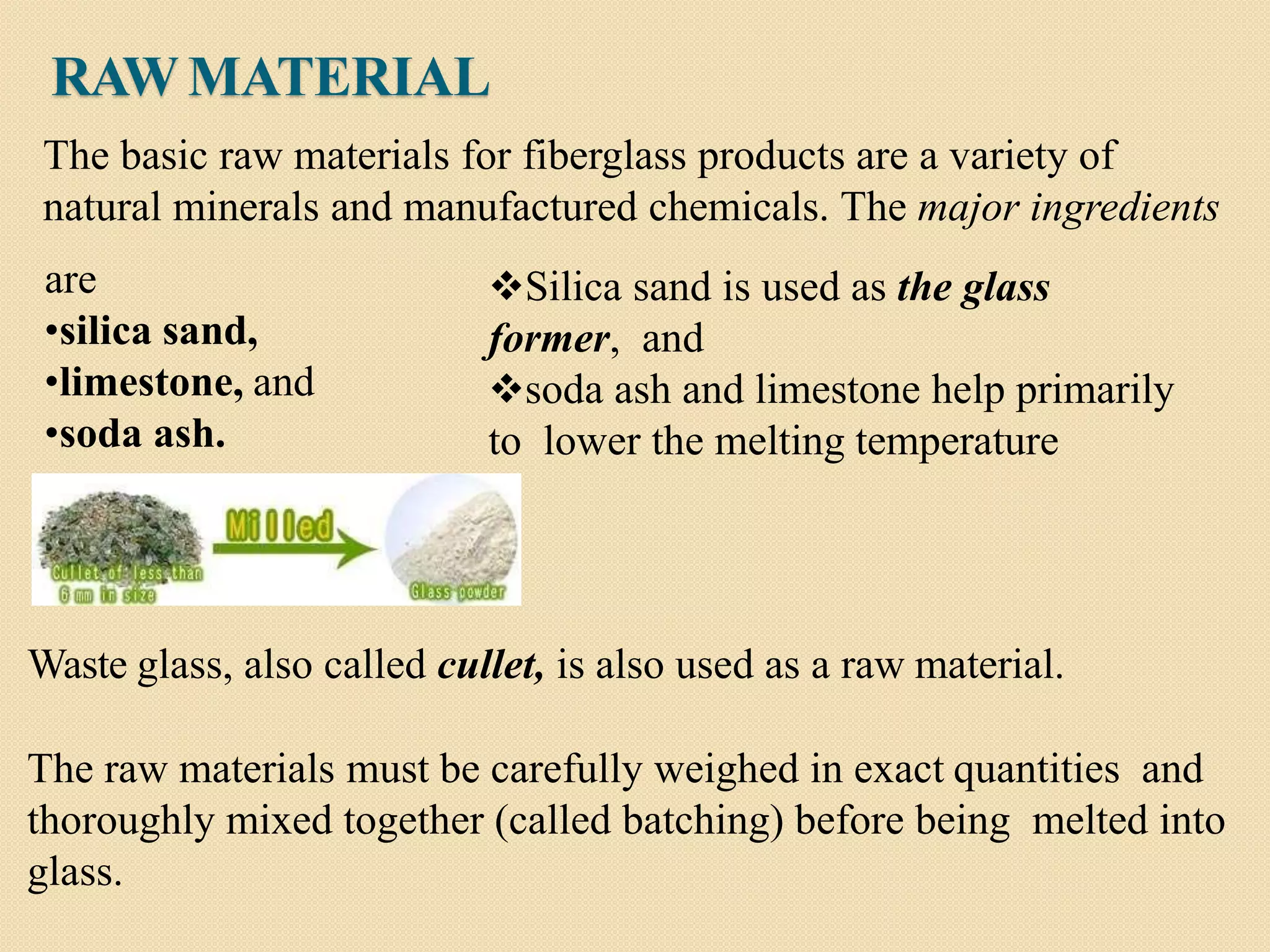

Fiberglass, or glass-reinforced plastic, is a composite material made of glass fibers set in a plastic resin. The document discusses the manufacturing process of fiberglass, which involves heating glass into a molten form and forcing it through fine holes to create thin glass filaments. It also summarizes the various types and properties of fiberglass, such as its chemical resistance, dimensional stability, tensile strength, and use as an electrical insulator. Applications mentioned include fiberglass roofing, structural daylight panels, and architectural designs that take advantage of fiberglass's molding abilities.