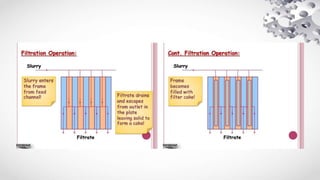

The plate and frame filter press uses alternating plates and frames to filter slurries. As the slurry passes through the filter cloth on the plates, the solids form a filter cake in the frames. Multiple plates and frames operate in parallel to provide a large surface area for filtration. The filter cake can be washed by including additional washing plates that allow wash water to pass through the cake. While effective for high value products, the plate and frame filter press has high costs and requires significant labor to operate.