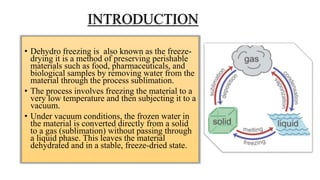

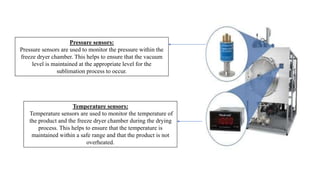

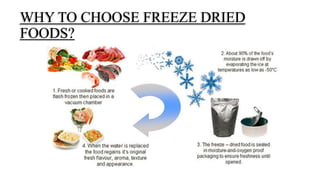

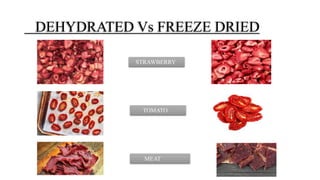

This document discusses dehydro freezing or freeze drying, which is a method of preserving perishable materials like food and pharmaceuticals. It involves freezing the material and then applying a vacuum so that the frozen water sublimates from solid to gas without passing through the liquid phase. Freeze dryers are used to remove water through sublimation in an industrial setting. They have components like a vacuum chamber, vacuum pump, condenser, temperature and pressure sensors, heating source and control system to carefully monitor and control the freeze drying process. Various types of freeze dryers exist for different applications. Freeze drying is useful for preserving foods like fruits, vegetables, coffee, eggs and meats as it retains nutrients, taste and texture better than other preservation