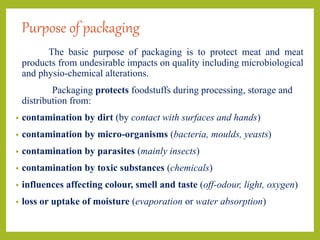

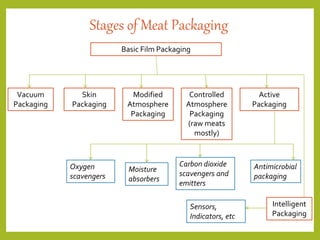

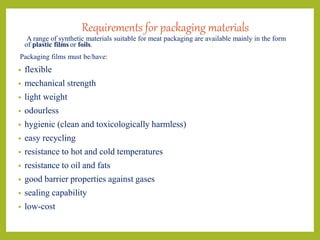

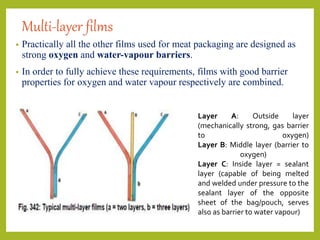

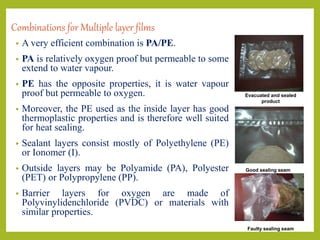

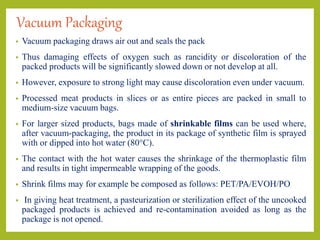

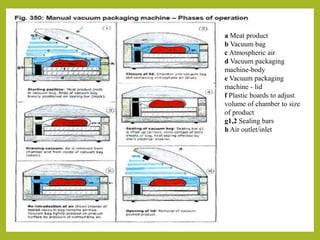

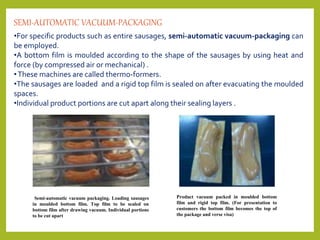

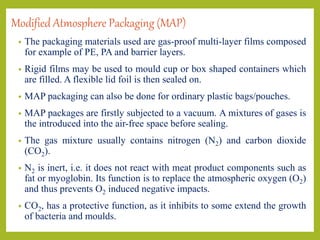

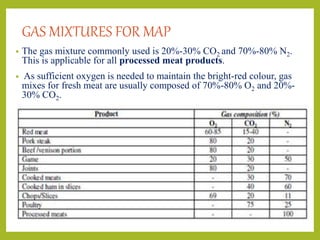

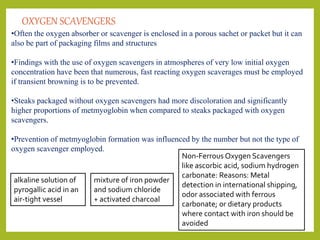

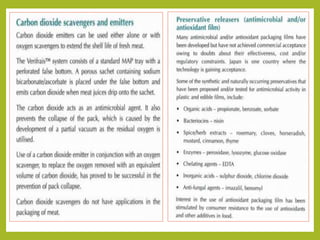

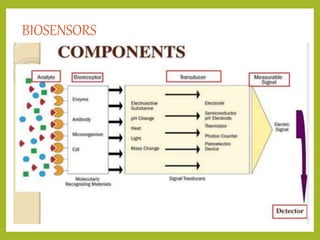

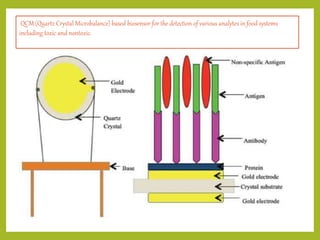

The document outlines the purpose and methods of meat packaging, emphasizing the need to protect meat products from various contaminants and quality degradation. It details different packaging techniques such as vacuum and modified atmosphere packaging, as well as the materials and properties required for effective meat packaging. Additionally, it discusses advanced packaging technologies, including active and intelligent packaging systems designed to extend shelf life and monitor product quality.