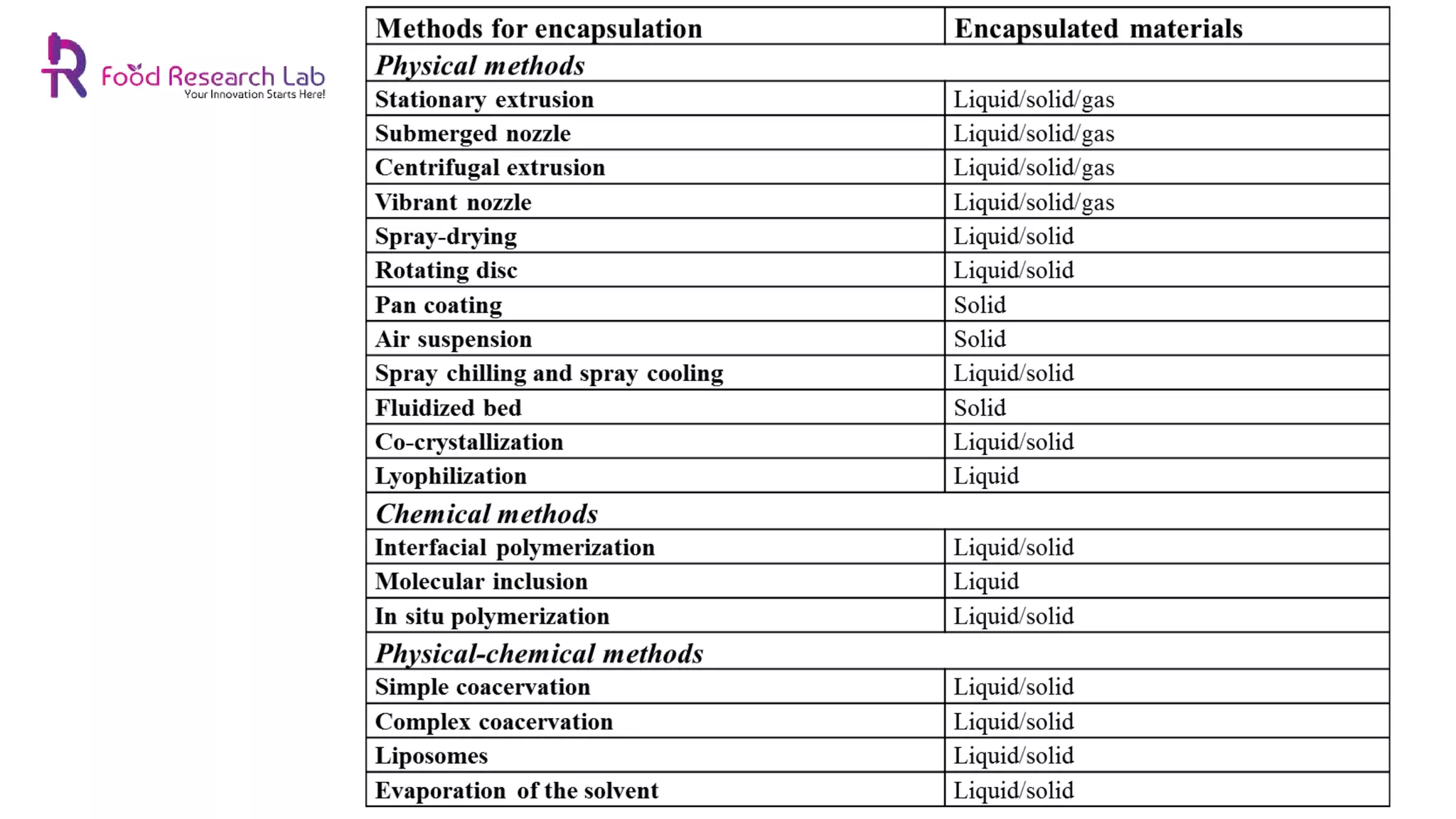

Dr. Nancy Agnes's presentation covers the encapsulation process in the food industry, essential for protecting ingredients and enhancing product shelf life. It discusses various encapsulation methods, including coacervation and spray drying, and highlights innovative applications such as improving the stability of fish oils and reducing bitterness in caffeine. The market for food encapsulation is projected to grow significantly due to its benefits in preserving volatile flavors and nutrients.