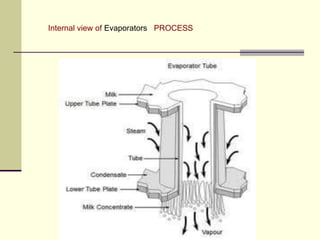

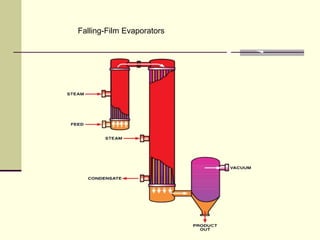

An evaporator is a device that uses heat to remove water from liquids through vaporization. There are several types of evaporators used in food processing, including batch pan evaporators, natural circulation evaporators, forced circulation evaporators, rising film evaporators, falling film evaporators, and rising/falling film evaporators. Each type uses a different design and configuration of heating elements and liquid flow to efficiently evaporate water out of foods and concentrates.