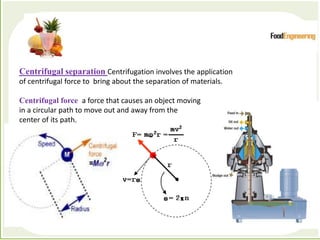

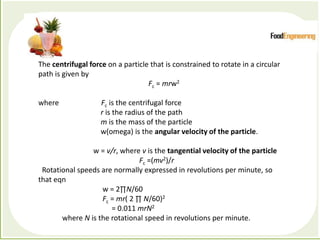

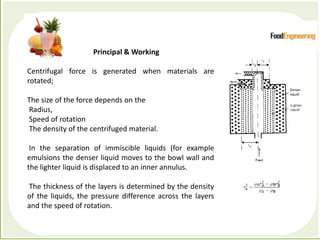

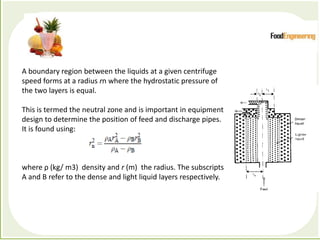

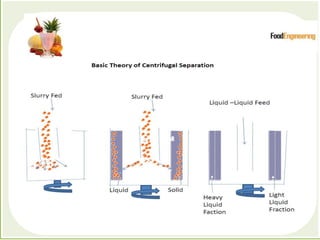

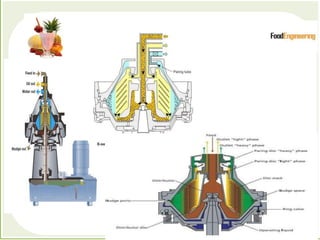

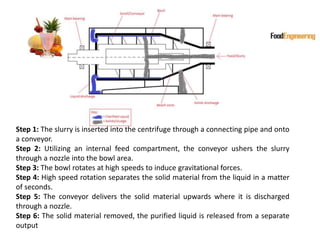

The document discusses mechanical separation processes that rely on physical forces to separate components. It focuses on centrifugal separation, explaining that centrifugal force is generated by rotating materials and depends on radius, rotational speed, and density. Centrifugal separation separates immiscible liquids based on density differences, with the denser liquid moving outward. Decanter centrifuges are also discussed, separating solids from liquids in slurries through high-speed rotation that exploits differences in buoyancy. Key applications include wastewater treatment, food processing, and oil/chemical industries.