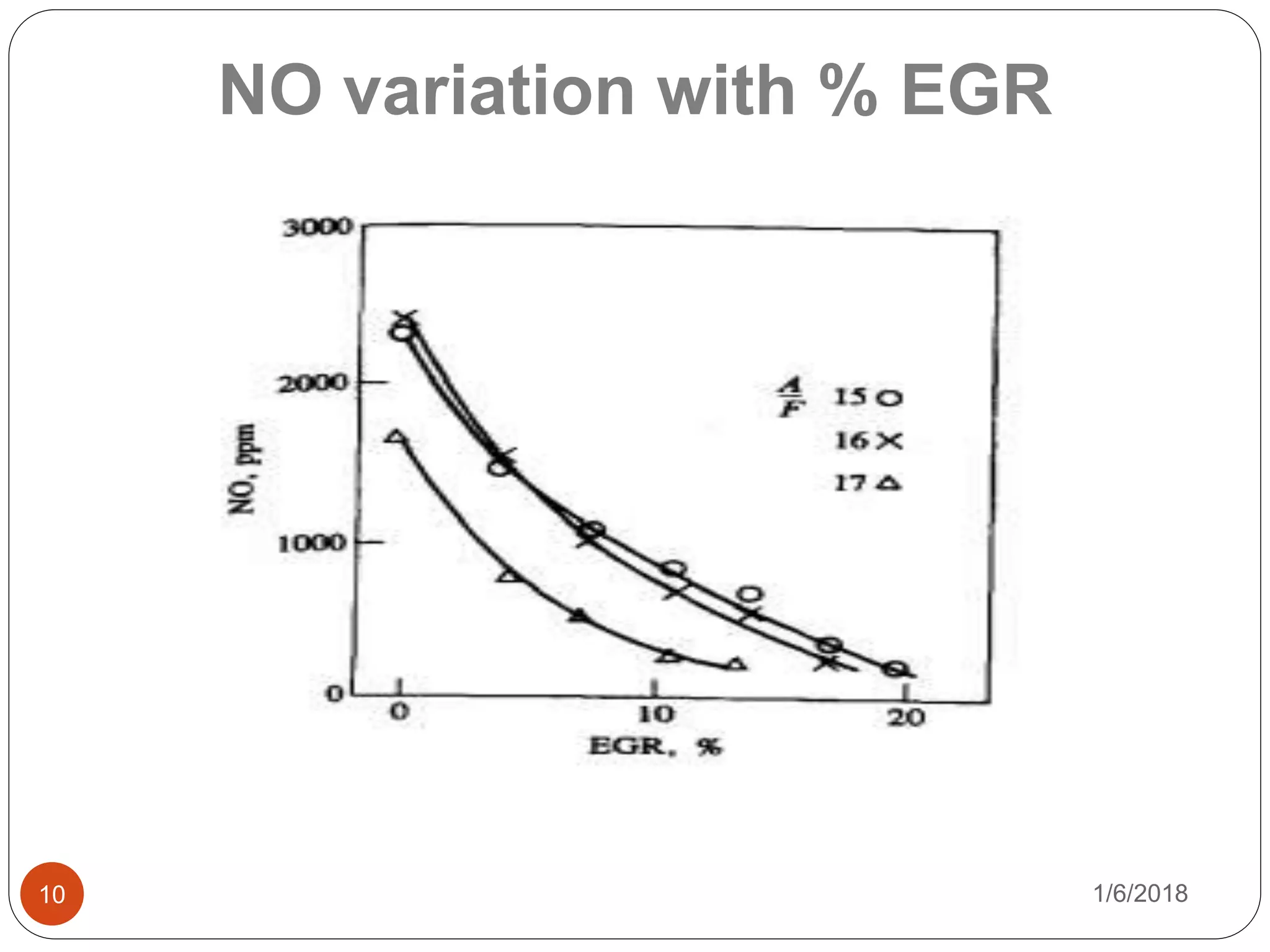

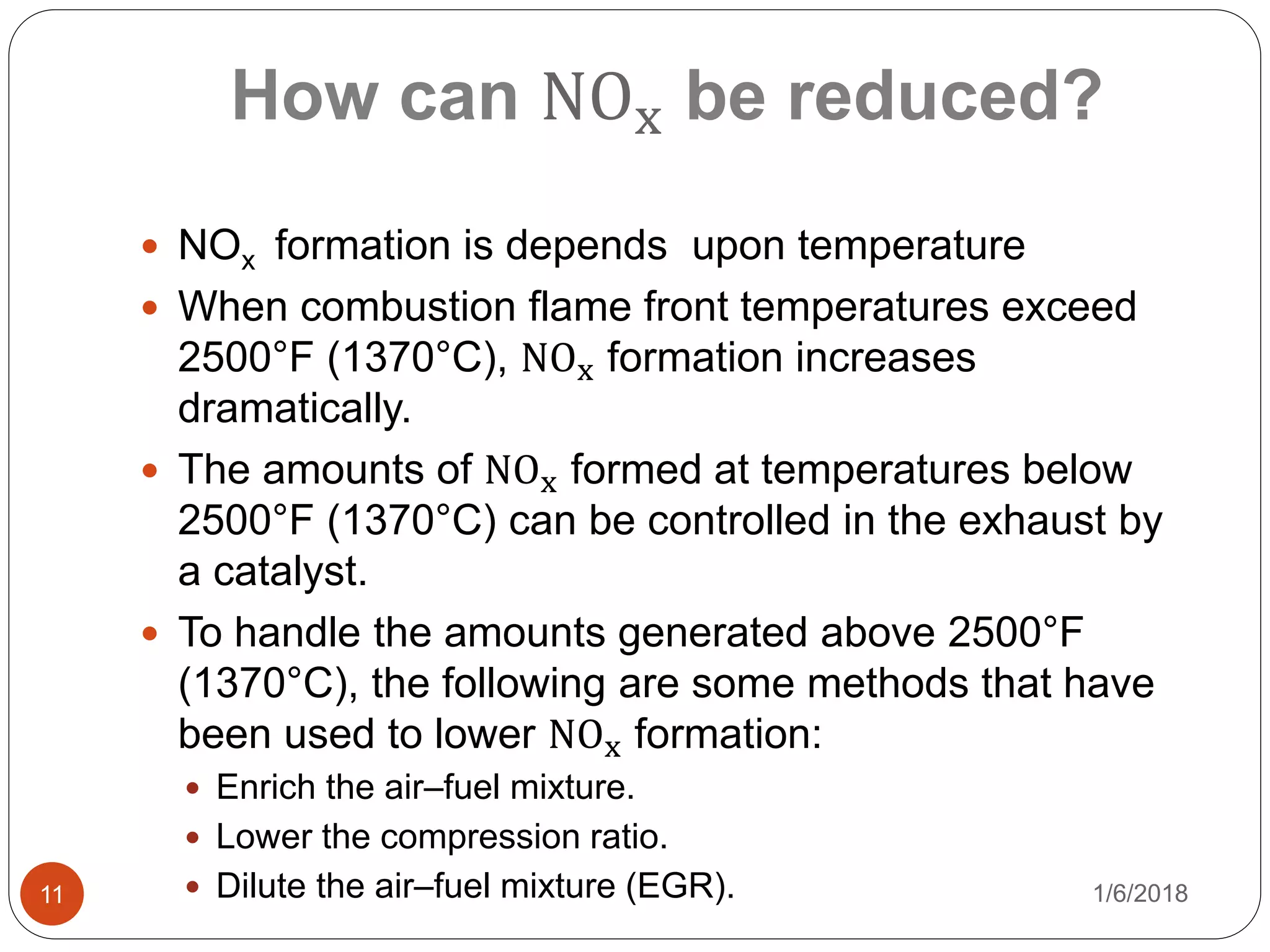

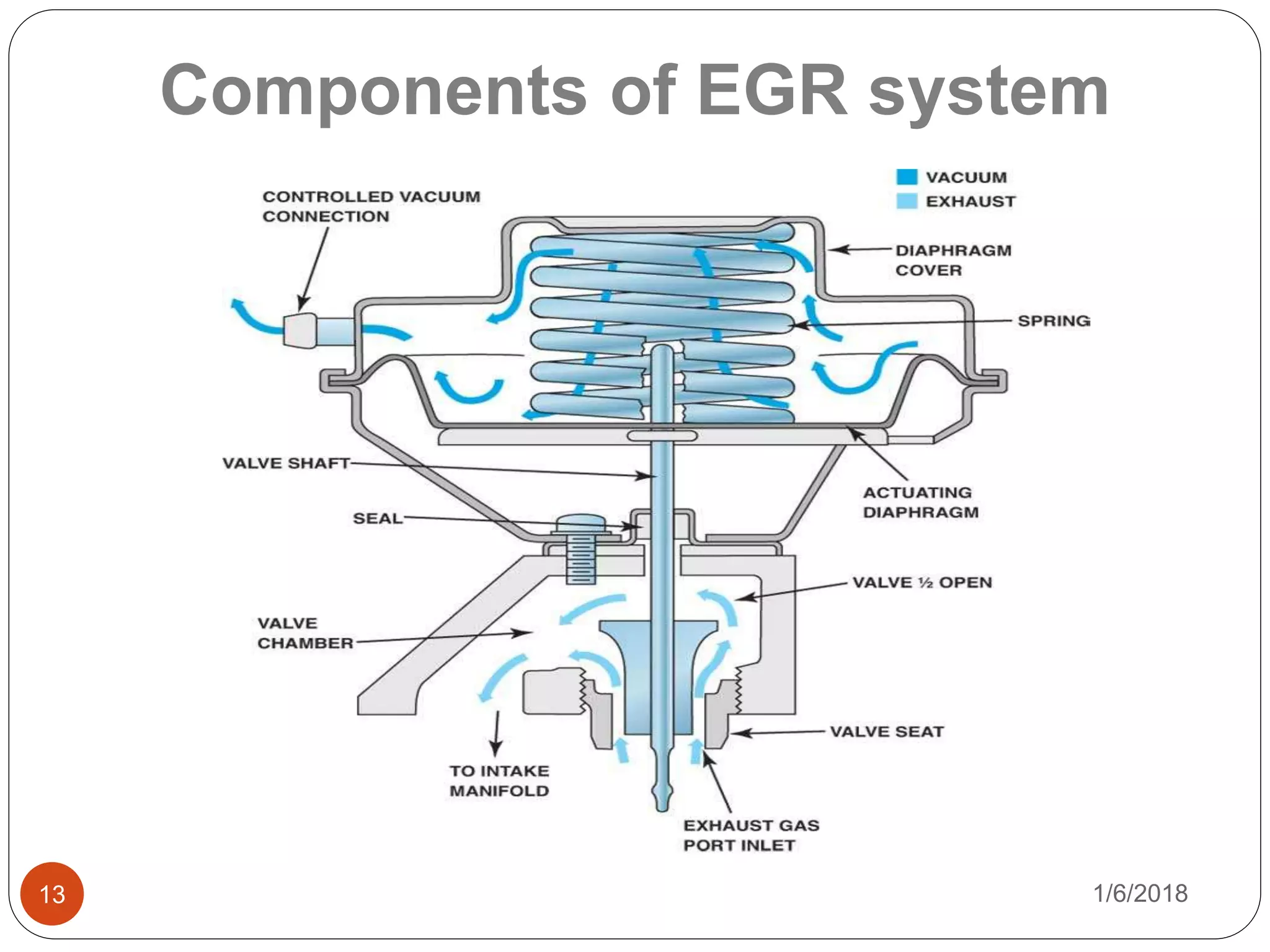

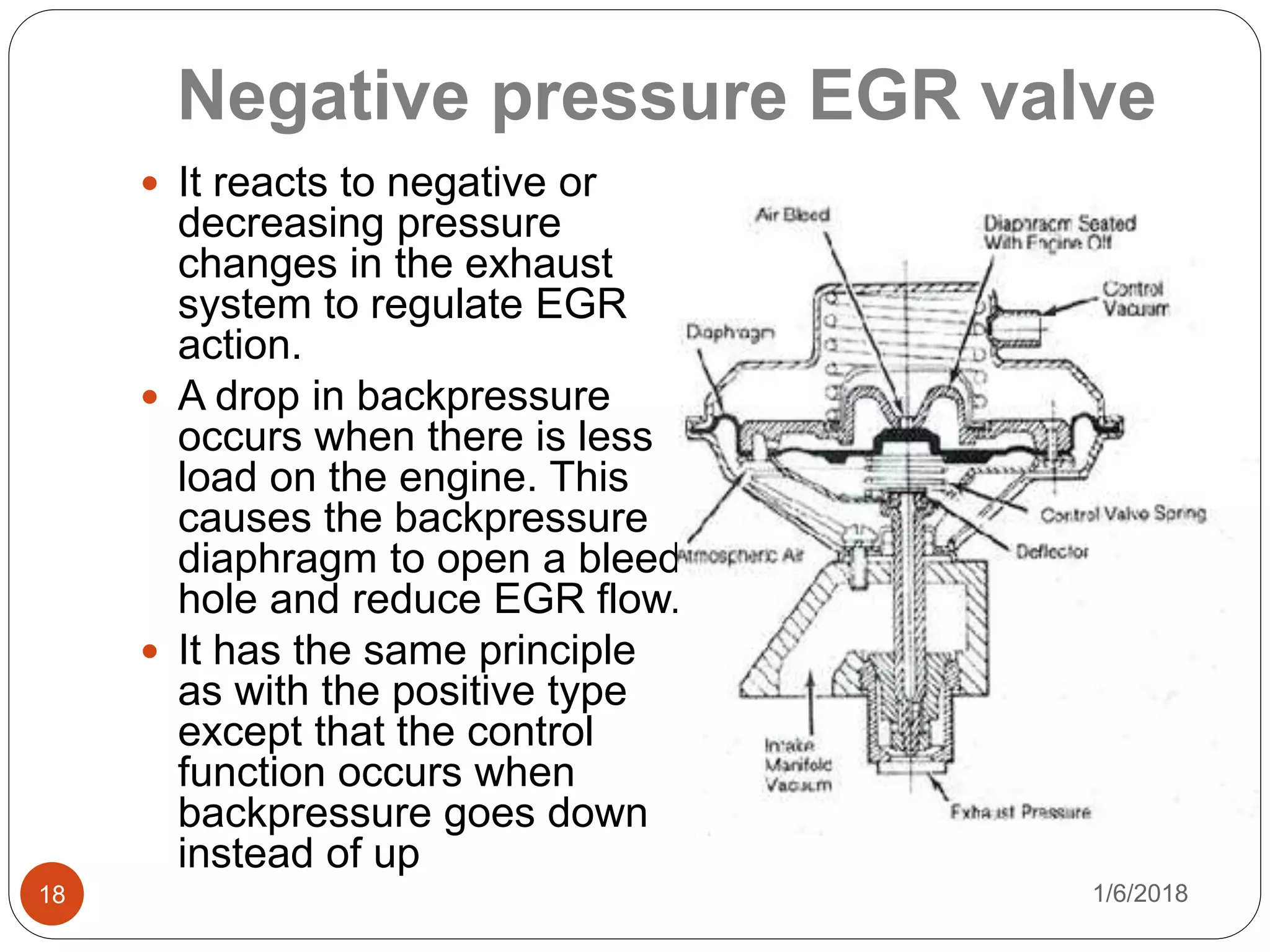

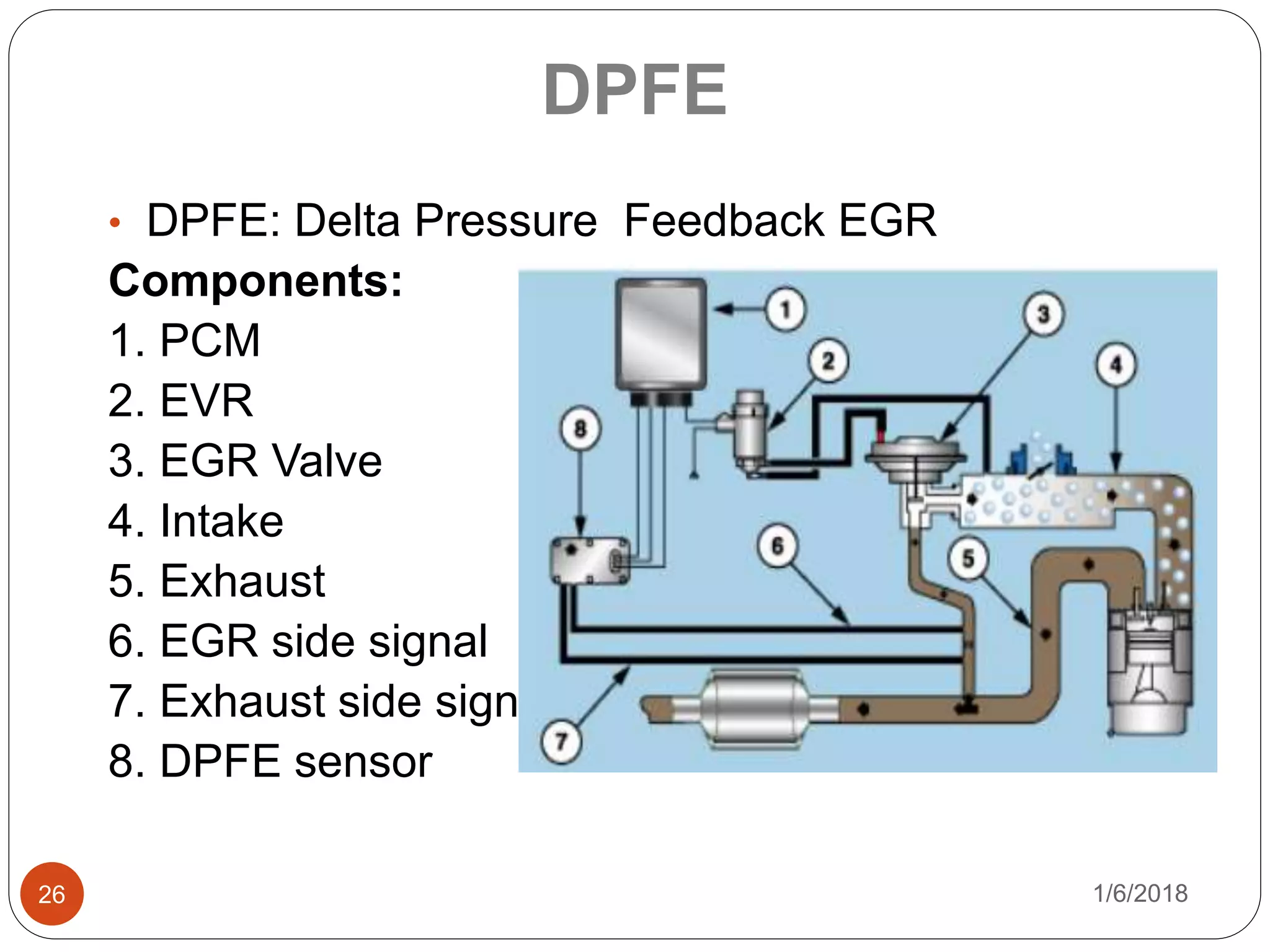

The document discusses exhaust gas recirculation (EGR) and its use in internal combustion engines to reduce NOx emissions. It first defines NOx as oxides of nitrogen produced during combustion and describes the mechanisms of NO and NO2 formation. It then discusses factors that affect NOx production and methods to reduce it, including EGR. The document explains the components and working of an EGR system, including different types of EGR control valves. It outlines the advantages of EGR in reducing temperatures and NOx, as well as potential disadvantages in power reduction. Finally, it briefly discusses EGR feedback systems used by engine control modules.