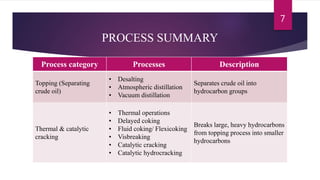

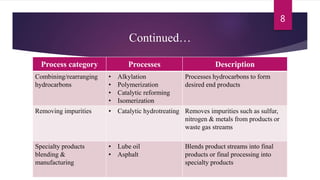

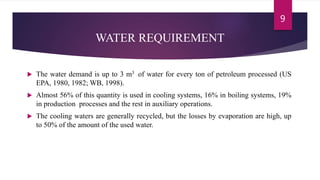

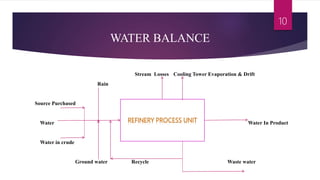

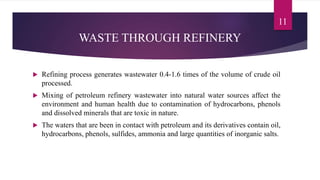

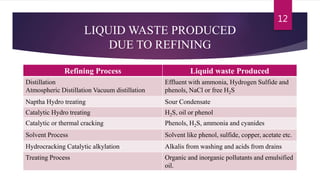

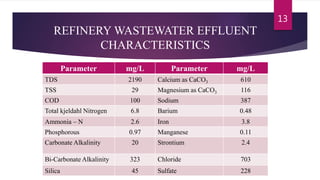

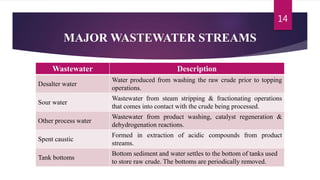

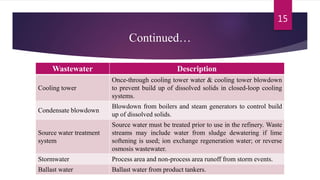

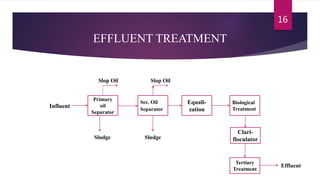

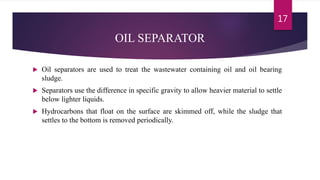

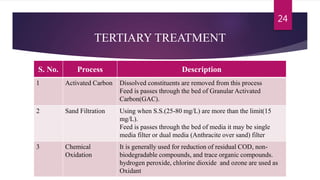

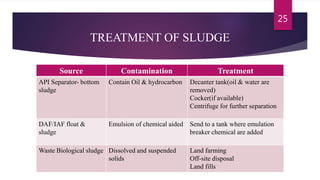

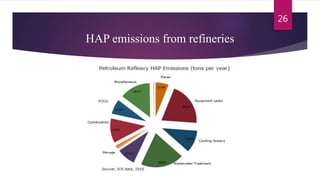

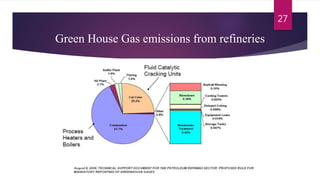

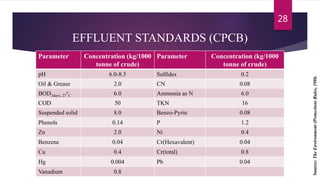

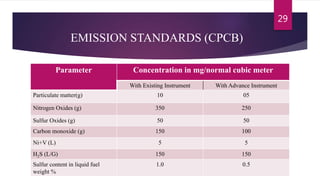

The document provides an overview of petroleum refineries, detailing their processes, products, and environmental impacts, particularly focusing on wastewater generation and treatment. It notes the significant amounts of water required for refining and highlights the characteristics and treatment methods for wastewater produced during refining. Additionally, it outlines the regulatory standards for effluent and emissions to mitigate the environmental effects of refinery operations.