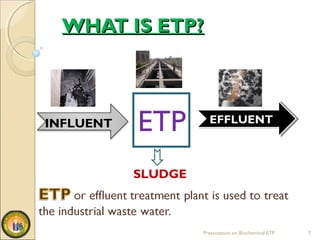

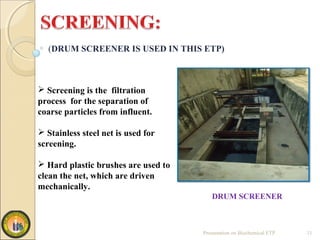

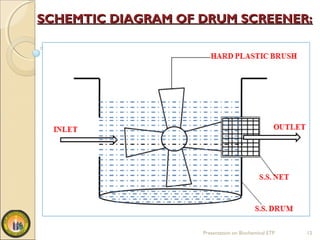

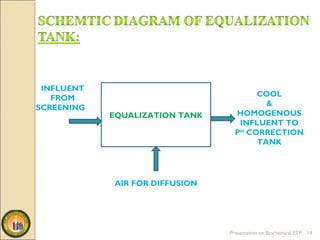

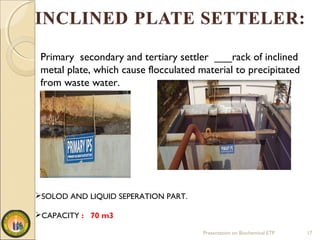

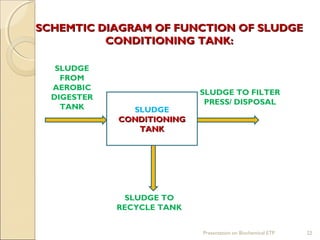

This document is a presentation on a biochemical effluent treatment plant (ETP). It provides details on the various processes within the ETP including screening, equalization, flocculation, sedimentation, and aerobic digestion. It describes the functions of key components like the drum screener, equalization tank, flocculation tanks, sequencing batch reactor, inclined plate settlers, and aerobic digester tank. Diagrams illustrate the overall flow process and functions of components like the drum screener and sludge conditioning tank. The presentation was prepared by Mazadul Hasan Sheshir for the Department of Wet Processing Technology at Southeast University in Bangladesh.