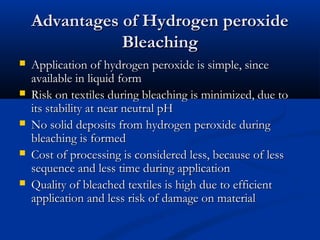

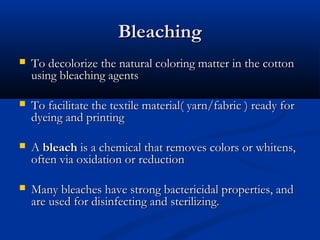

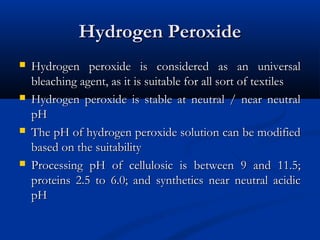

The document discusses the bleaching of cotton textiles, focusing on the purpose of bleaching to remove natural pigments and prepare the fabrics for dyeing. It details various bleaching techniques, primarily oxidative methods using agents like calcium hypochlorite and hydrogen peroxide, and highlights the importance of maintaining proper pH levels during the process. Additionally, it covers the chemical reactions involved in each bleaching agent's application and the advantages of using hydrogen peroxide as a bleaching agent.

![Problems in Hypochlorite BleachingProblems in Hypochlorite Bleaching

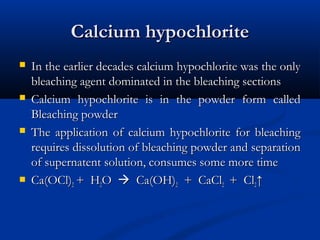

In Ca(OCl)In Ca(OCl)22 bleaching Ca(OH)bleaching Ca(OH)22 is converted to CaCOis converted to CaCO33 by theby the

reaction with COreaction with CO22. [Ca(OH). [Ca(OH)22 + CO+ CO22 CaCOCaCO33]]

This conversion reduces the alkali content in bleaching bath andThis conversion reduces the alkali content in bleaching bath and

decreases the pH, since CaCOdecreases the pH, since CaCO33 is insoluble in wateris insoluble in water

In NaOCl bleaching NaOH is converted to NaIn NaOCl bleaching NaOH is converted to Na22COCO33 which iswhich is

soluble in water [NaOH + COsoluble in water [NaOH + CO22 NaNa22COCO33]]

In both the bleaching, due to HCl formation during bleachingIn both the bleaching, due to HCl formation during bleaching

pH decreases commonlypH decreases commonly

To avoid this problem buffer like NaTo avoid this problem buffer like Na22COCO33 is required to be addedis required to be added

to maintain pH 9.5 to 11.0, the decrease of pH below 9 willto maintain pH 9.5 to 11.0, the decrease of pH below 9 will

cause damage to the polymercause damage to the polymer](https://image.slidesharecdn.com/3bleaching-181017151214/85/3-Bleaching-Process-ppt-13-320.jpg)

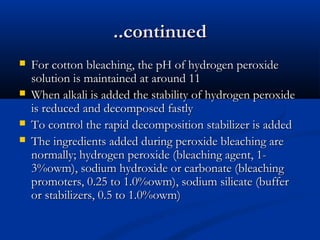

![……continuedcontinued

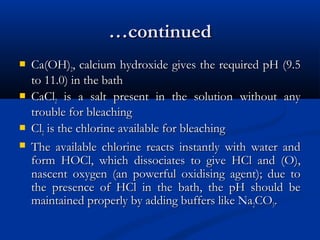

HH22OO22 ↔ H↔ H++

+ HO+ HO22

--

[stable][stable]

HOHO22

--

↔ [OH]↔ [OH]--

+ (O) [unstable]+ (O) [unstable]

In the alkaline condition the unstability ofIn the alkaline condition the unstability of

peroxide is continued by the concentrationperoxide is continued by the concentration

The liberation of nascent oxygen is utilized forThe liberation of nascent oxygen is utilized for

the oxidation reaction in a controlled manner bythe oxidation reaction in a controlled manner by

selecting the stabilisers to get uniformselecting the stabilisers to get uniform

applicationapplication](https://image.slidesharecdn.com/3bleaching-181017151214/85/3-Bleaching-Process-ppt-16-320.jpg)