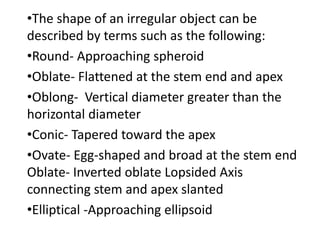

This document provides an overview of important engineering properties of agricultural crops including cereals, pulses, and oilseeds. It discusses various physical properties like size, shape, density, and thermal properties. It describes the structure and milling processes of various cereals like wheat, rice, and corn. It also discusses properties of pulses and common oilseeds and their uses. The document is intended to familiarize students with these engineering properties and how they influence the design of processing equipment.