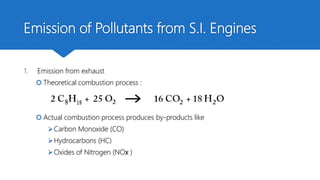

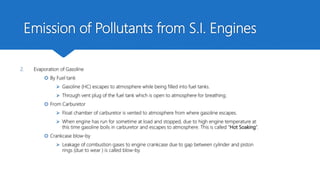

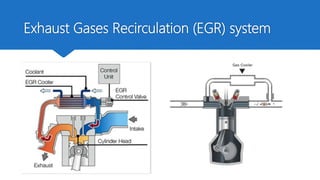

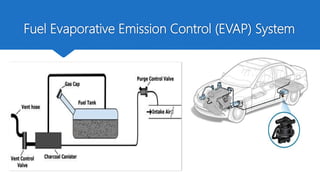

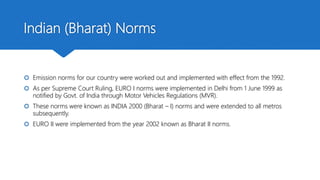

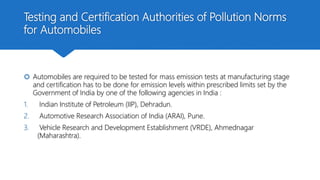

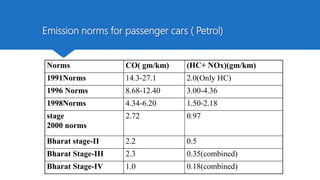

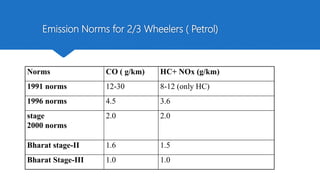

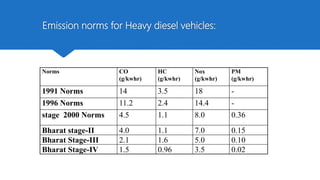

The document discusses engine emissions from both spark ignition (S.I.) and compression ignition (C.I.) engines, detailing the pollutants produced such as carbon monoxide, hydrocarbons, and oxides of nitrogen, as well as evaporation issues related to gasoline. It also covers pollution control strategies, including modifications in engine design and various treatment systems, such as catalytic converters and exhaust gas recirculation systems. Additionally, it outlines emission norms set by governments for vehicles, including the implementation of Euro and Bharat standards over the years to regulate pollutant levels.