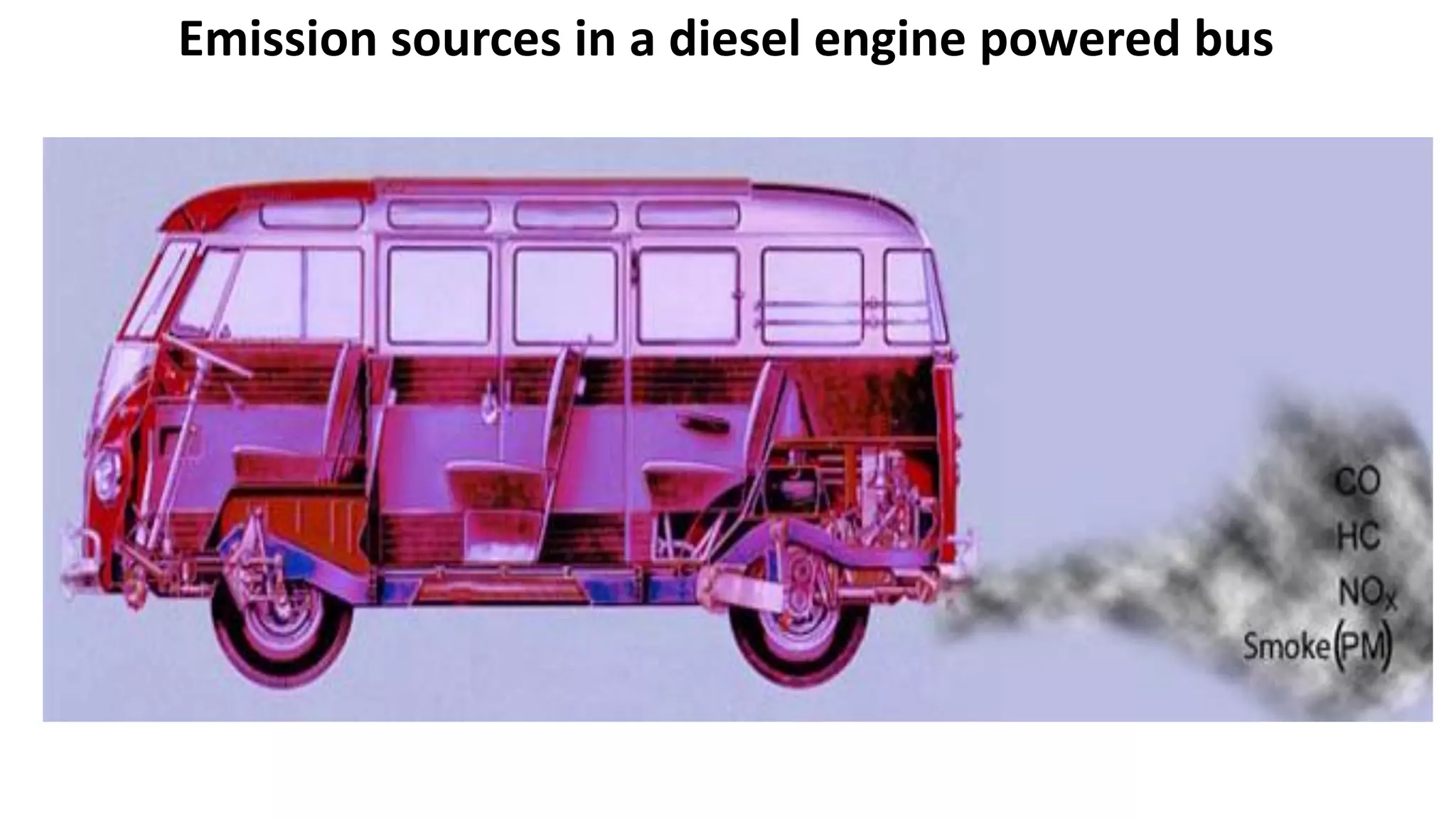

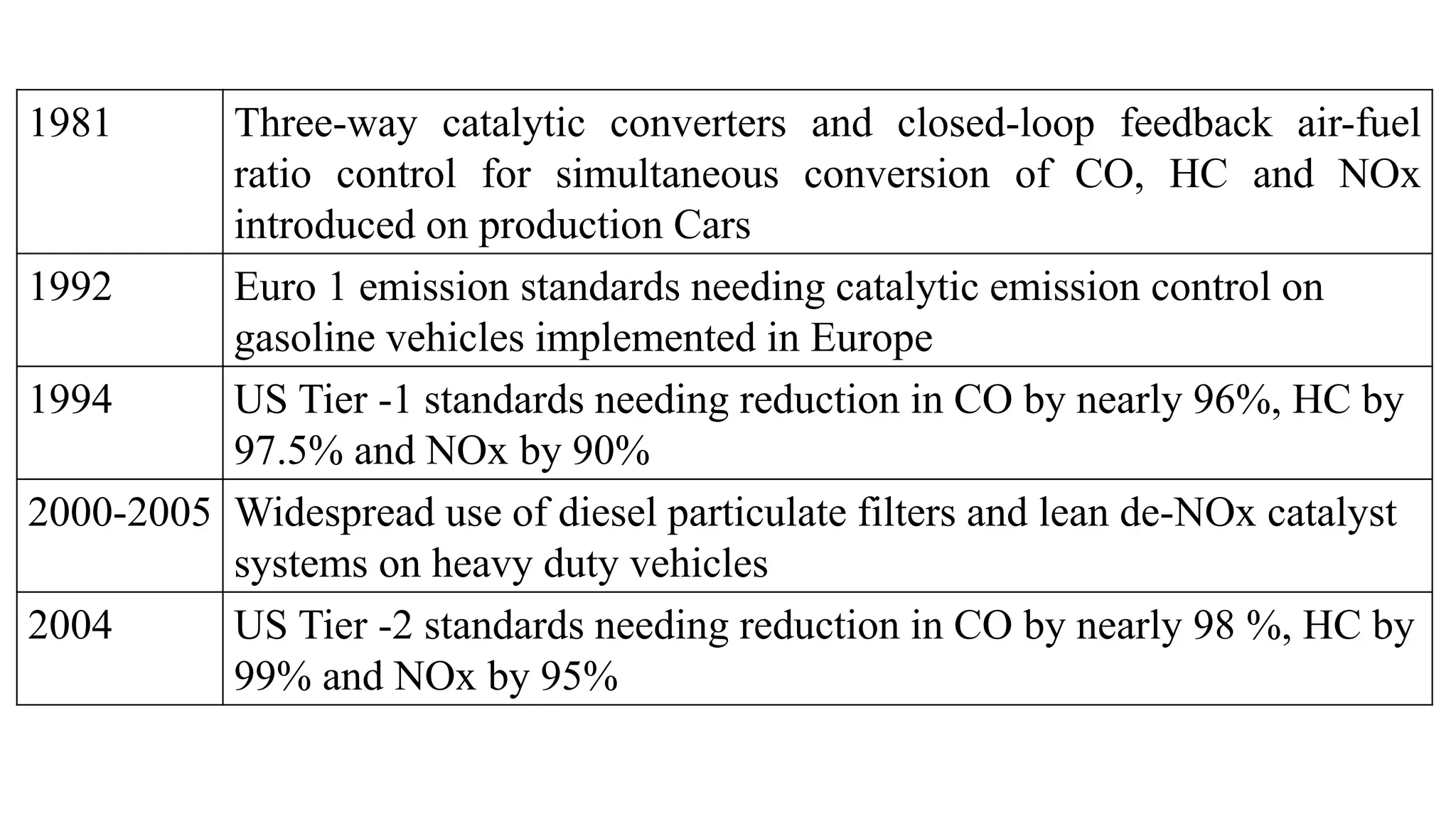

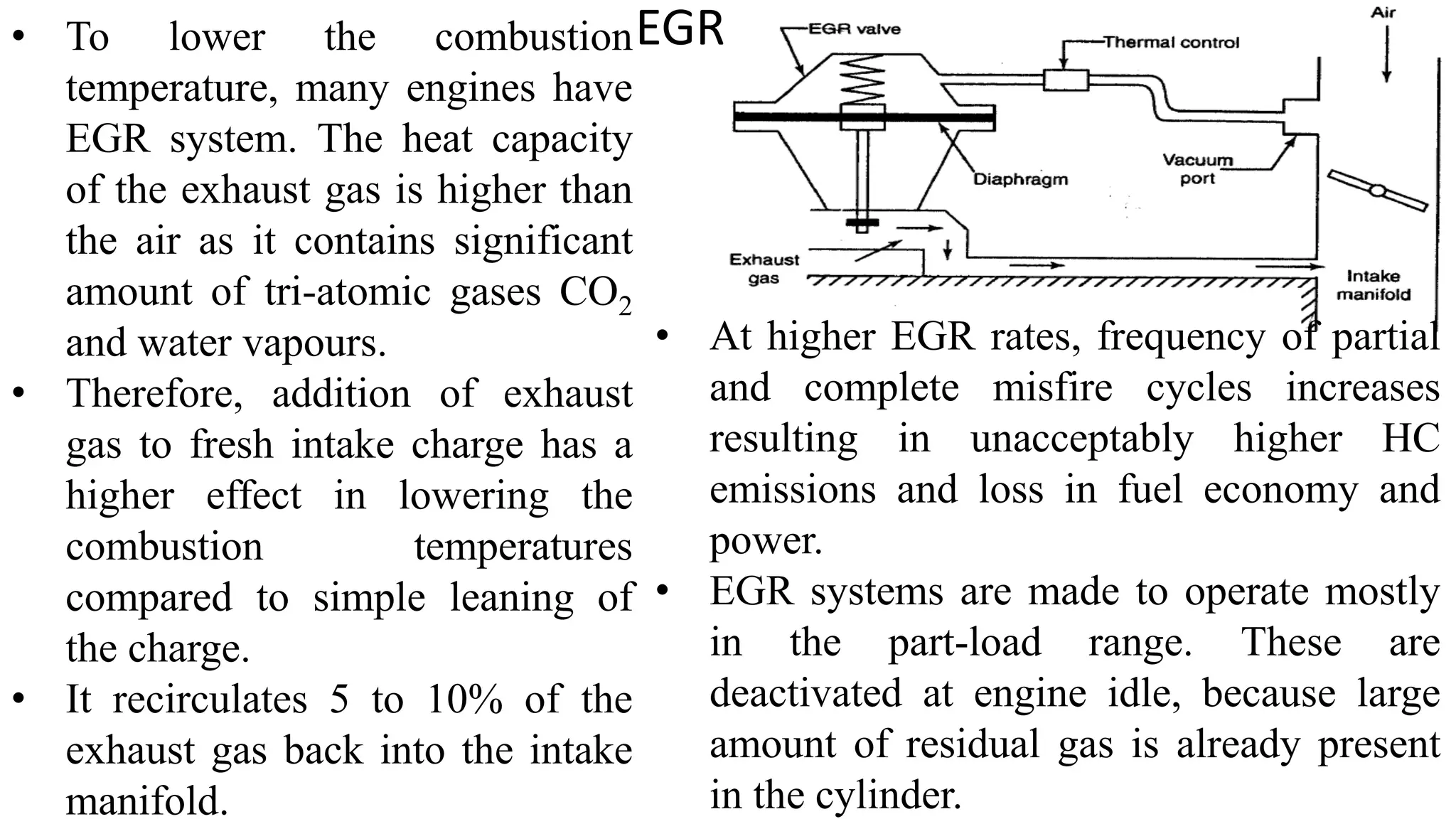

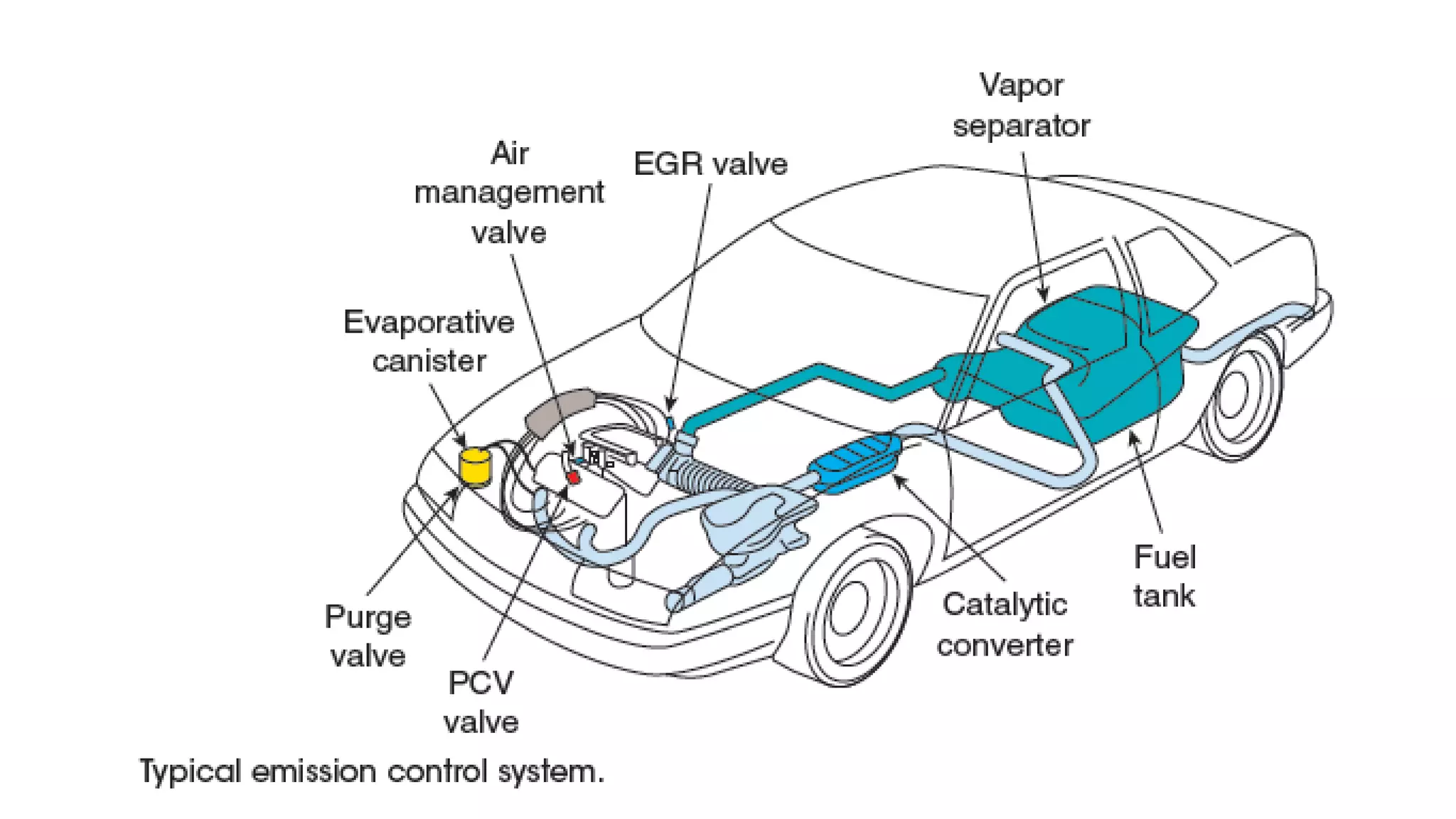

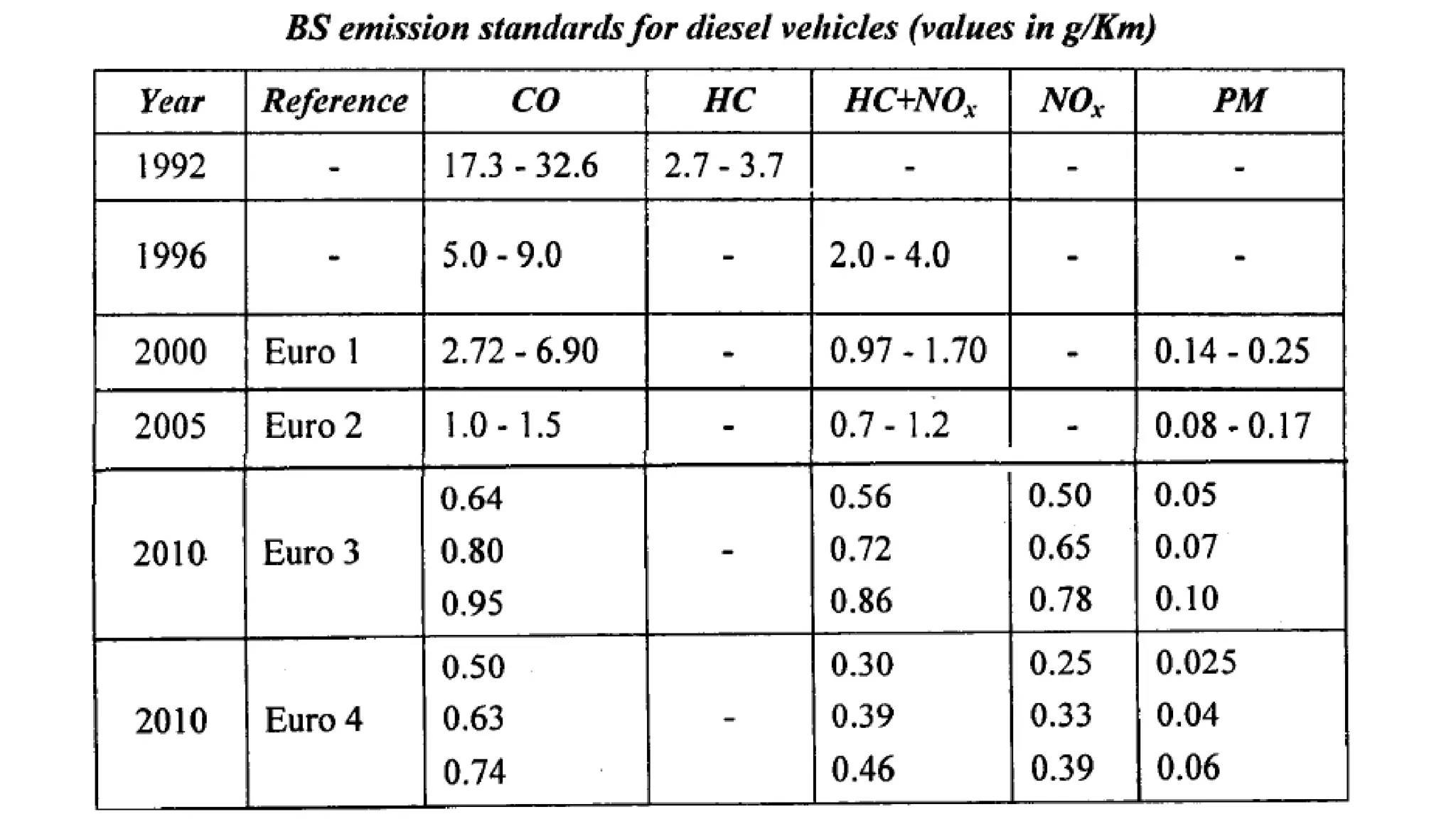

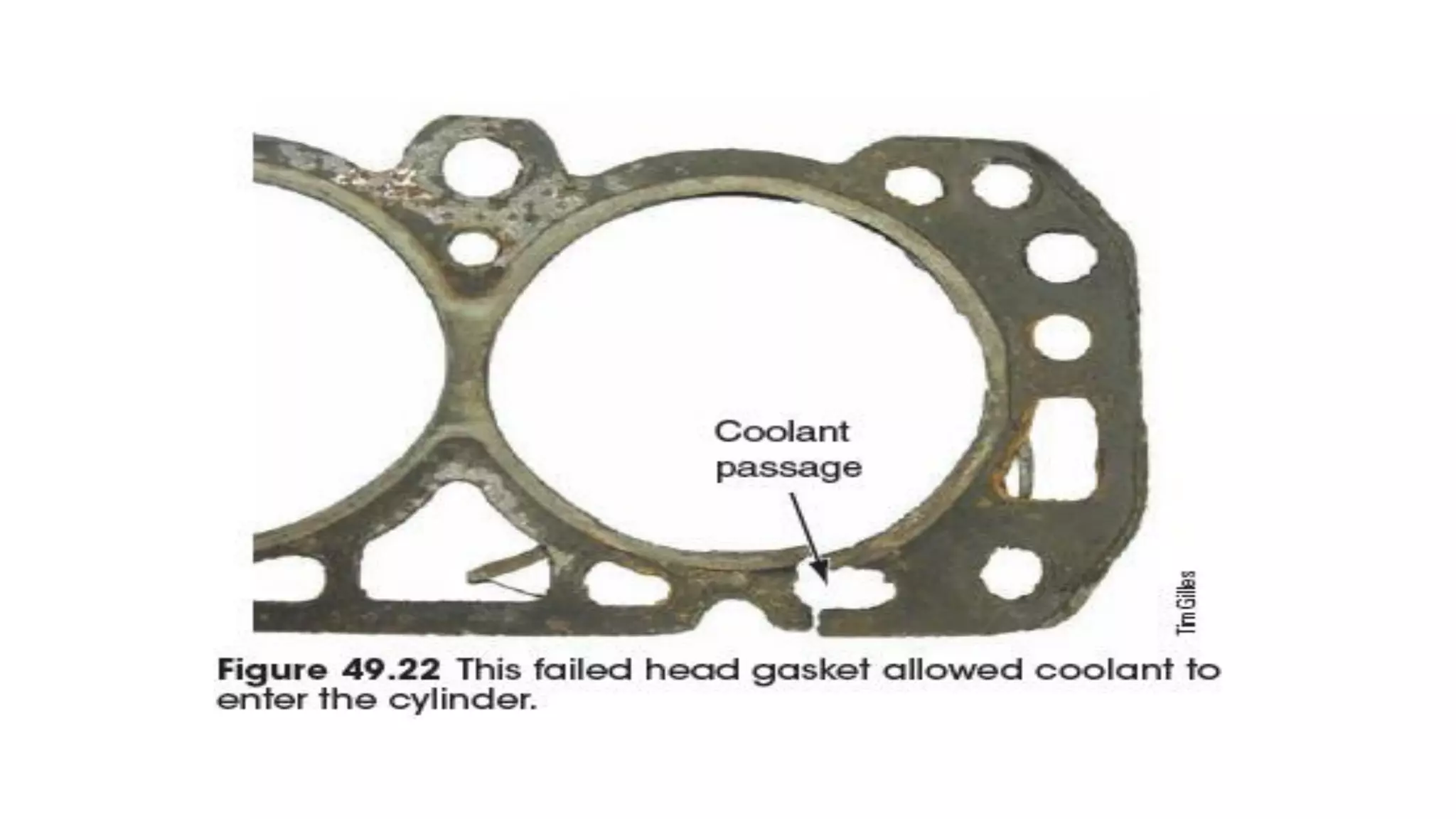

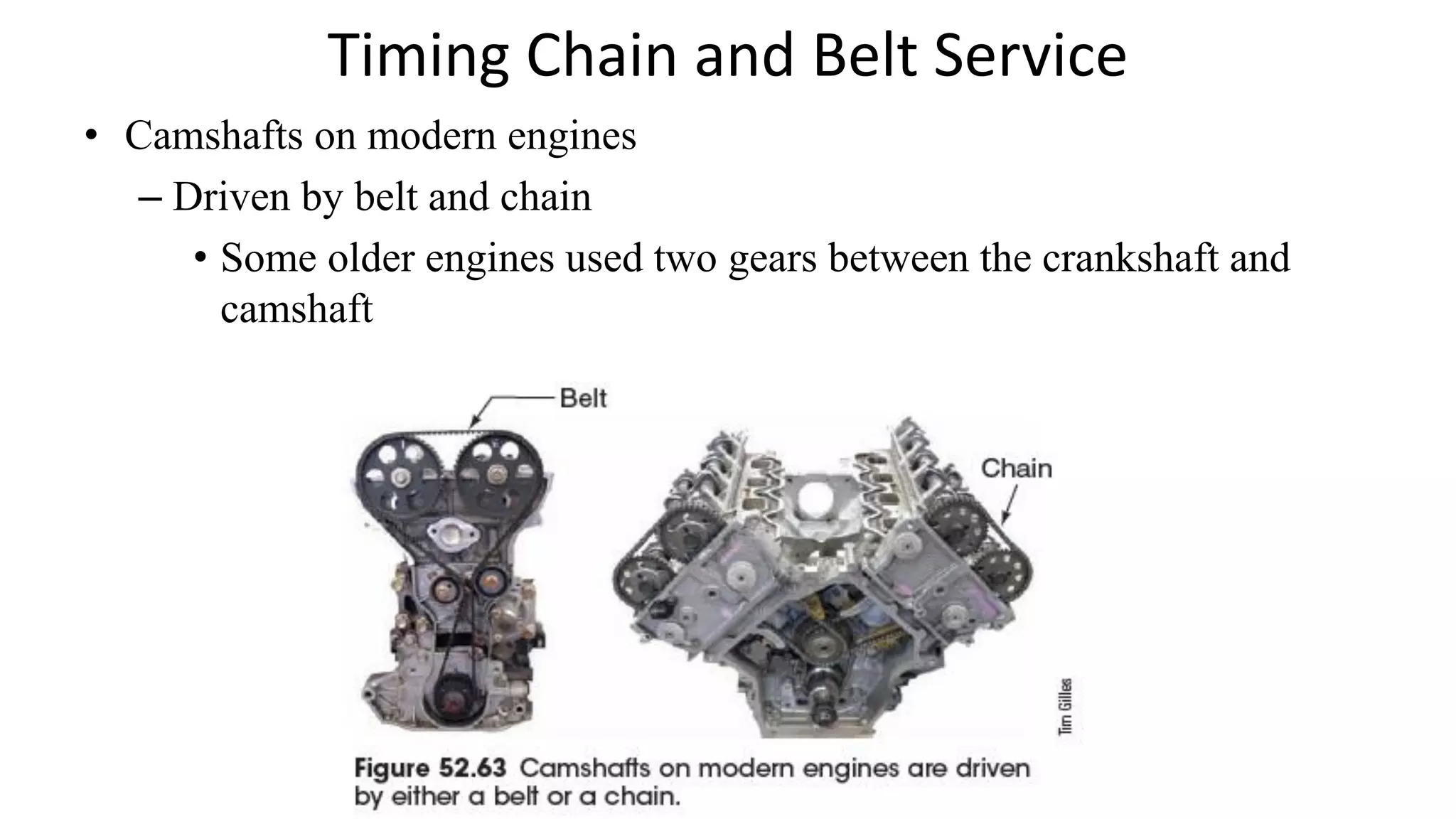

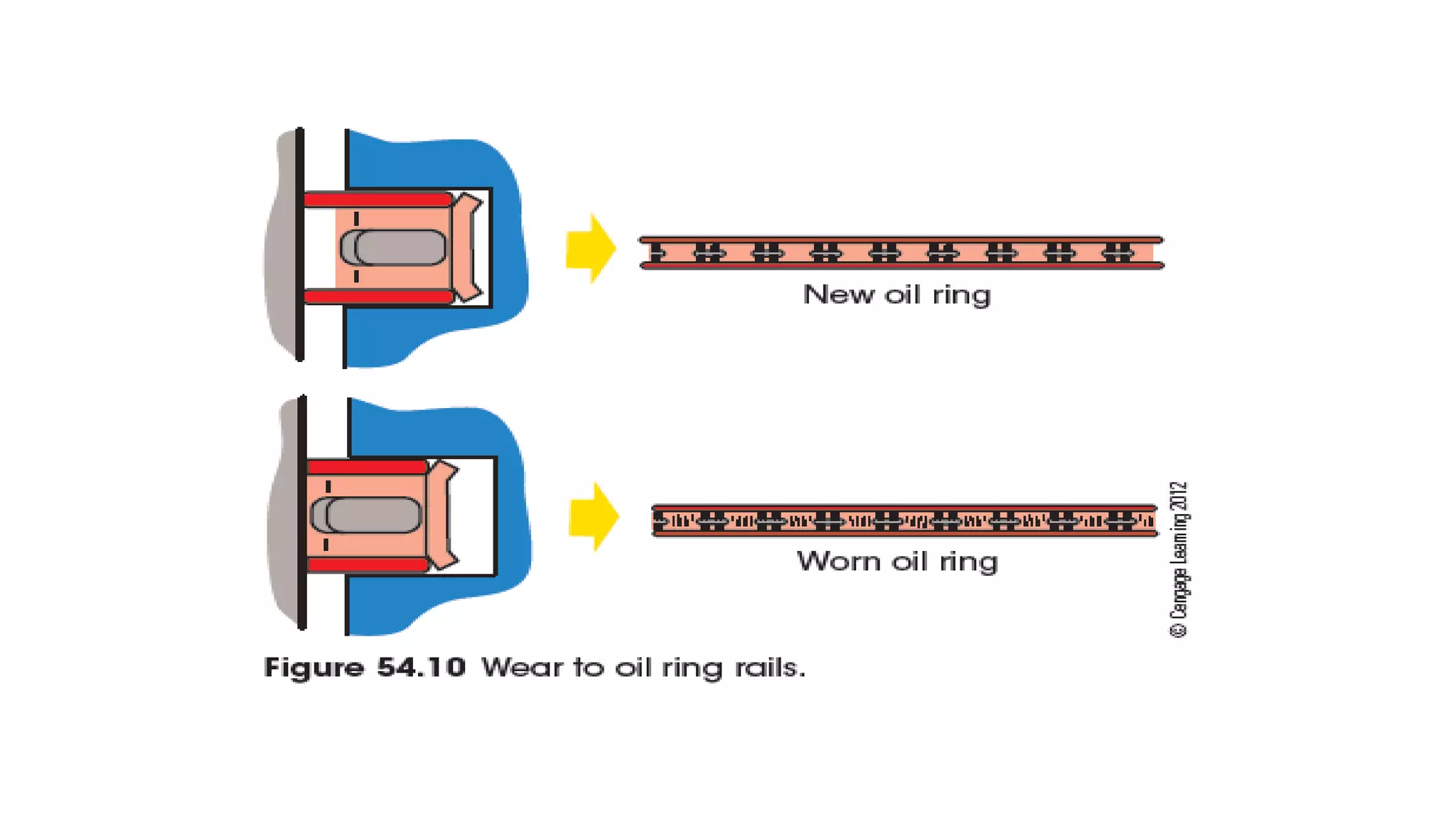

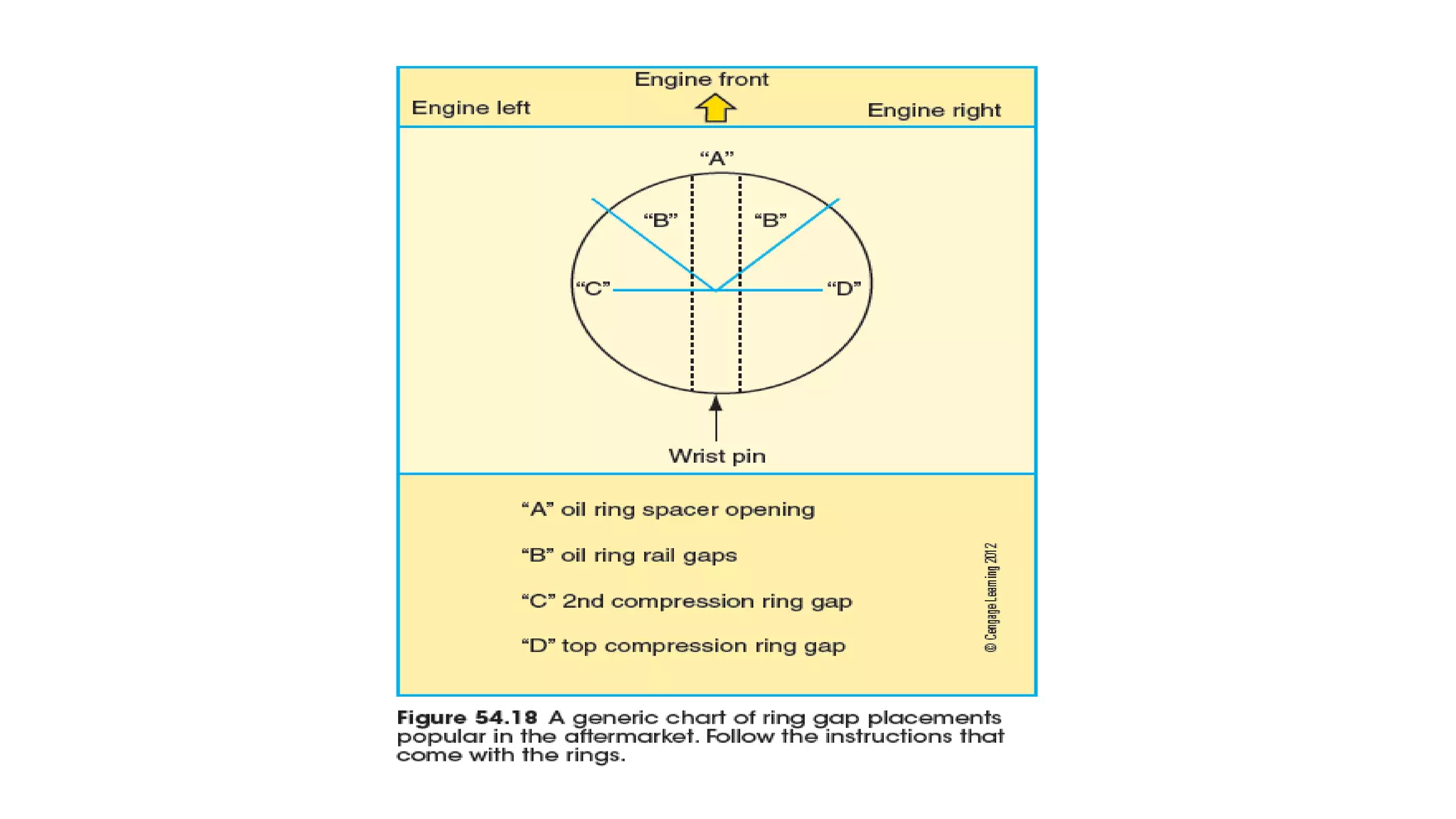

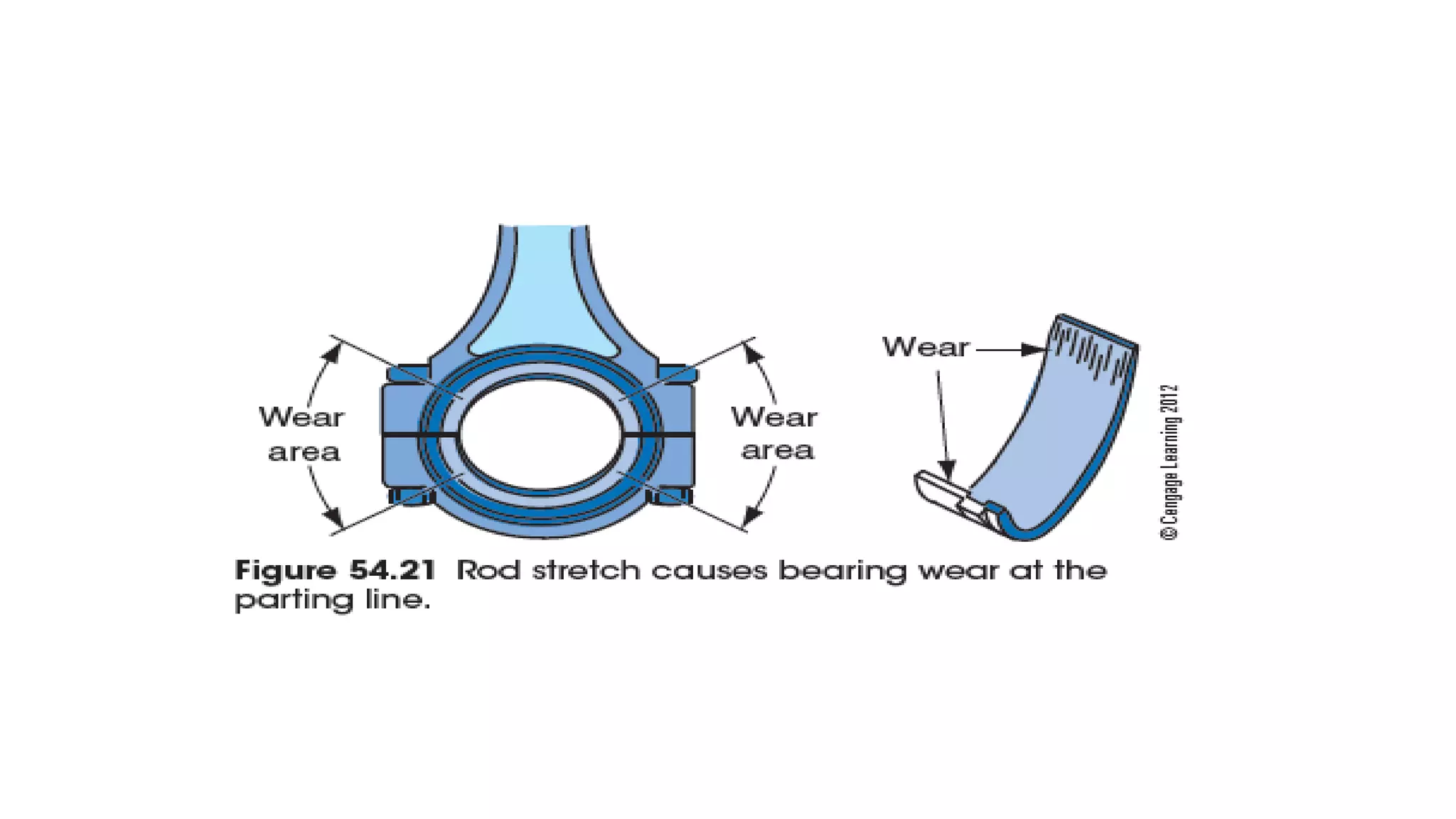

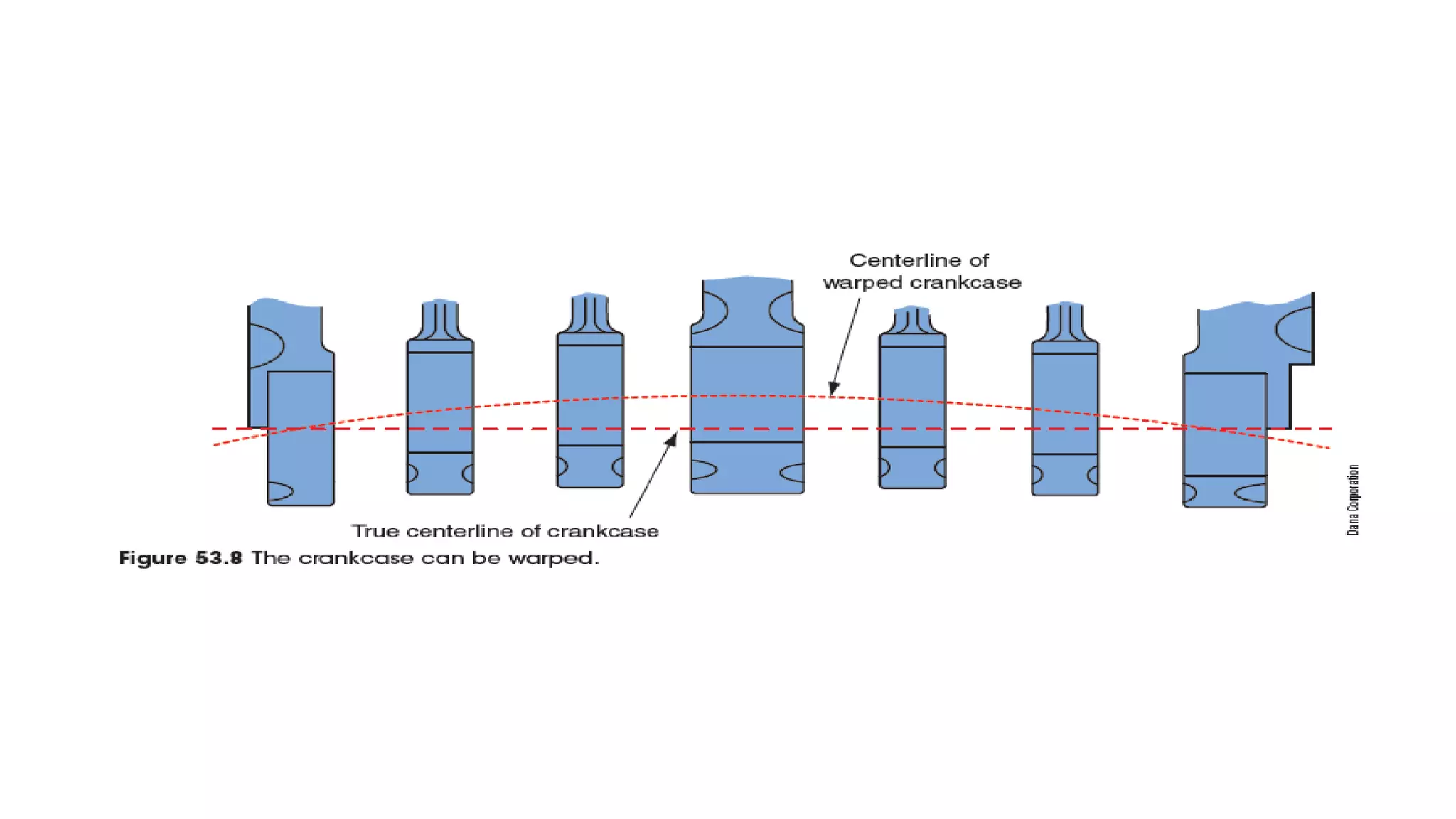

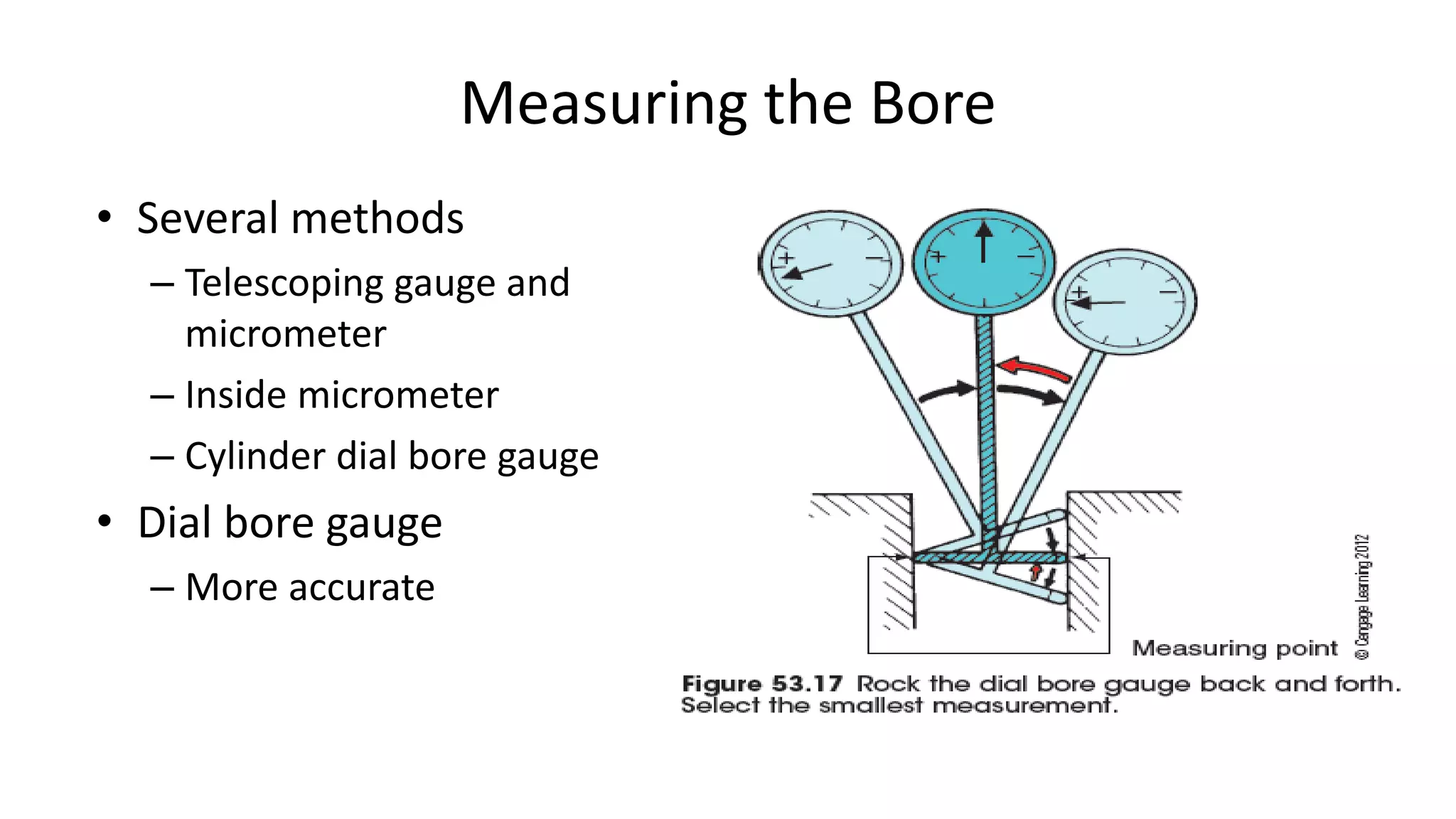

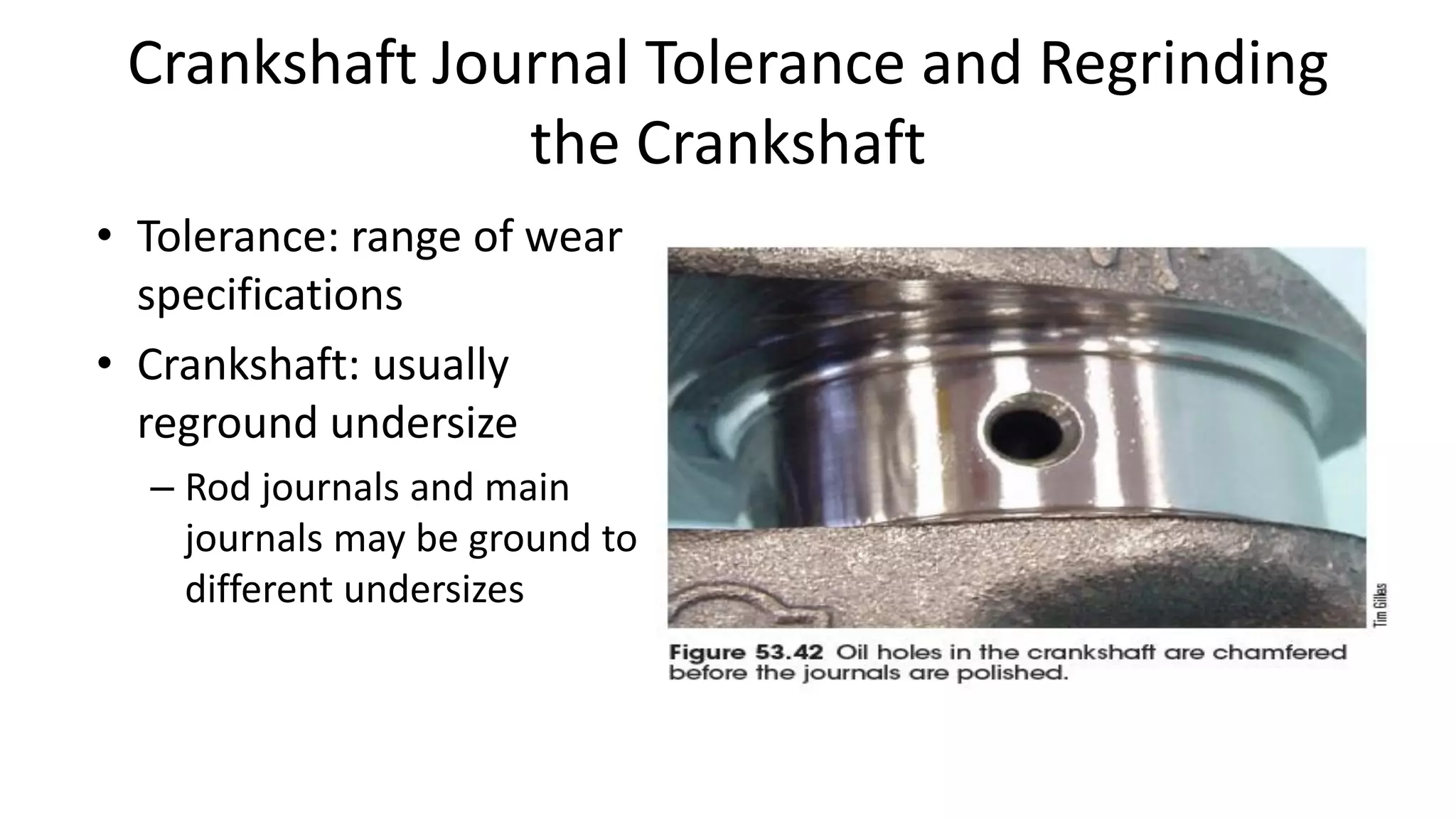

This document discusses engine emission control and service. It introduces the types of pollutants from internal combustion engines and how they are formed. It describes methods of controlling emissions, including engine modifications, exhaust gas treatment systems like catalytic converters, and the use of alternative fuels. It also covers national and international emission standards. The second part discusses servicing engine components like the cylinder head, valves, piston assembly, cylinder block, crankshaft, and engine reassembly precautions.