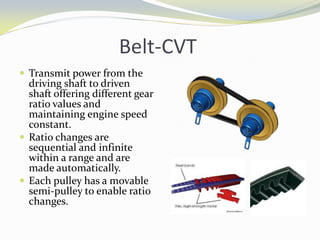

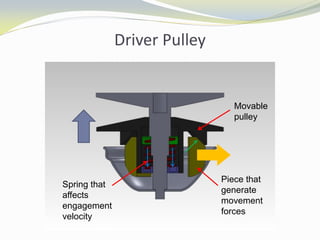

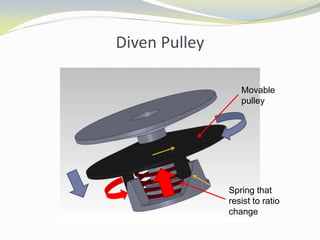

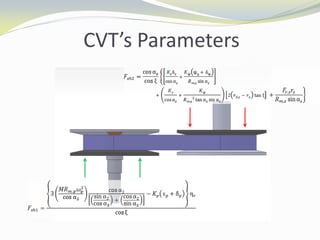

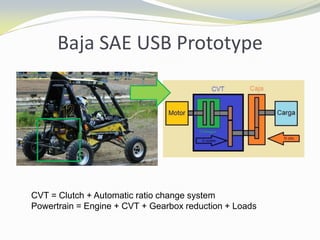

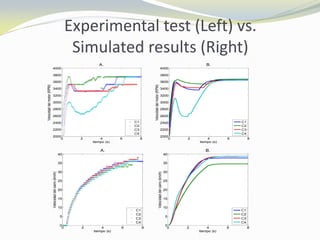

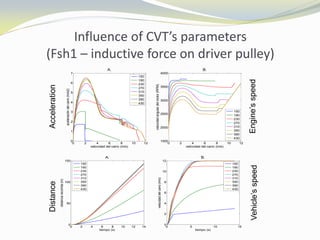

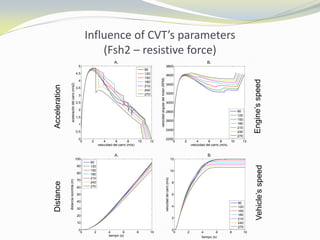

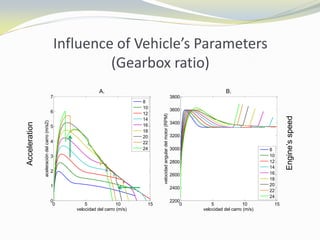

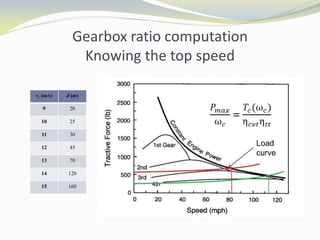

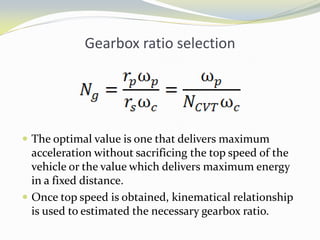

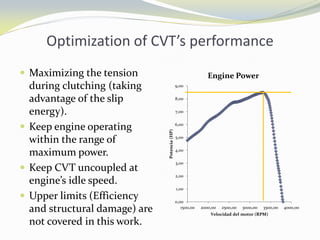

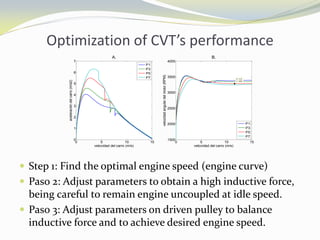

The document outlines a project aimed at creating a numerical simulation to study the impact of various parameters on the performance of a continuously variable transmission (CVT) in a vehicle. Key objectives include disassembling a CVT model to understand its internal workings, simulating vehicle motion under different conditions, and validating the model with experimental data. The findings suggest a methodology for optimizing transmission ratios and parameters to enhance vehicle performance, while also providing insights into the effects of parameters like inductive and resistive forces on the system's dynamics.