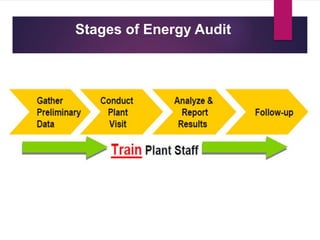

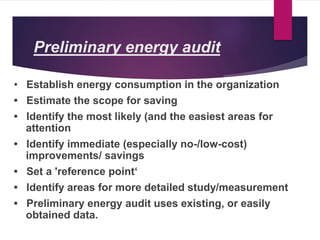

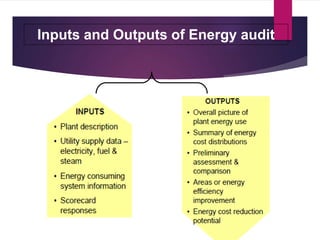

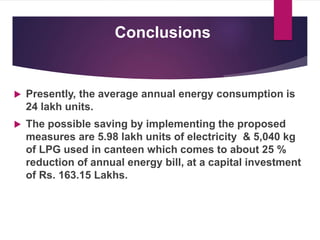

An energy audit is essential for systematic energy conservation efforts, involving the collection and analysis of energy-related data. It aims to identify energy consumption patterns, assess energy inputs and outputs, and implement energy-saving measures, ultimately reducing costs. Two types of audits are conducted: preliminary audits for general assessments and detailed audits for precise recommendations, potentially leading to a significant reduction in energy costs.