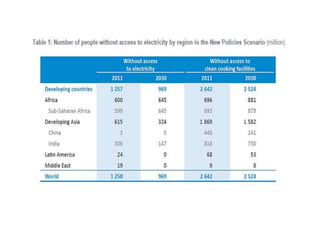

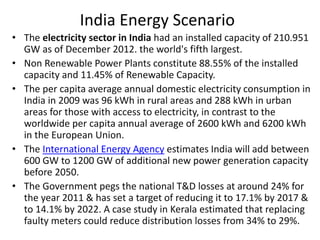

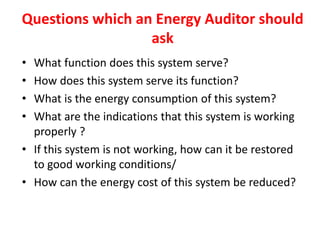

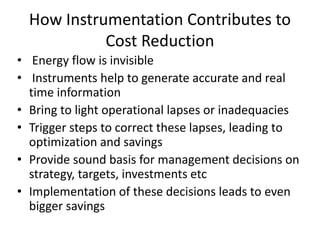

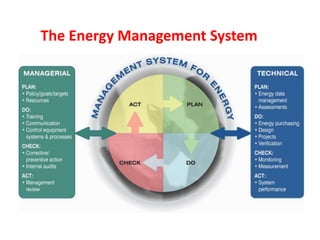

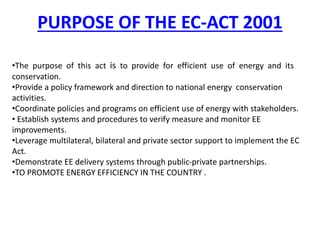

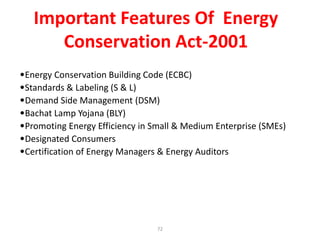

The document discusses the importance of energy management and auditing as essential tools for energy conservation and efficiency improvements in various sectors, including households, transportation, and industry. It outlines causes of energy crises, strategies for energy management, types of energy audits, and methods for reducing energy consumption and costs. Additionally, it covers the Energy Conservation Act of 2001, highlighting its objectives and impact on promoting energy efficiency in India.