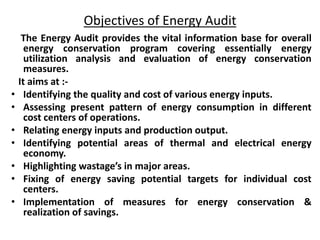

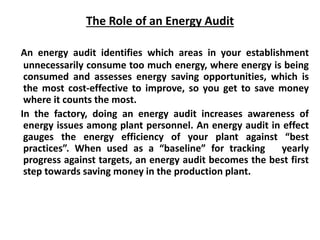

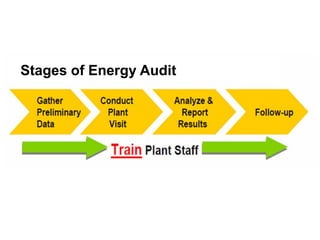

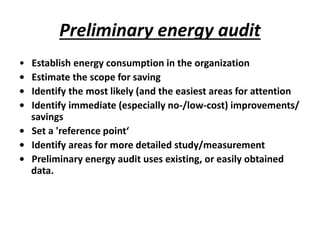

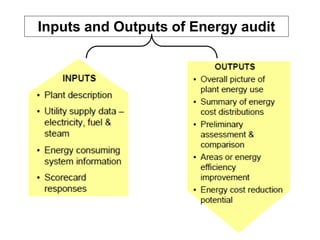

This document discusses energy auditing and management. It defines an energy audit as the systematic collection and analysis of energy data to identify conservation opportunities. The objectives are to identify current energy usage and costs, assess consumption patterns, relate usage to production, highlight inefficiencies, and set savings targets. An energy audit process includes a preliminary audit using existing data to establish a baseline and identify focus areas, followed by a more detailed audit using advanced instrumentation to account for 95% of energy usage and develop engineering recommendations. The audit outputs include an assessment of management structures, a need for metering and monitoring, and an action plan prioritizing energy projects and setting budgets for savings.