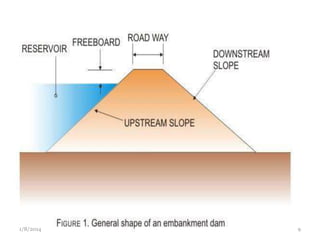

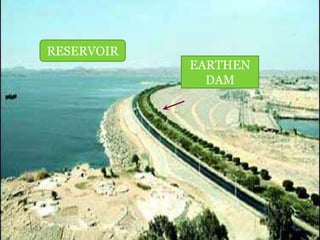

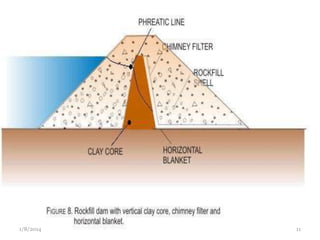

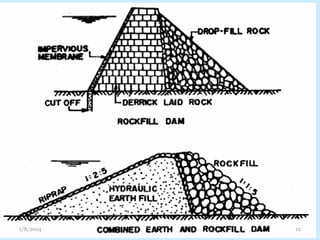

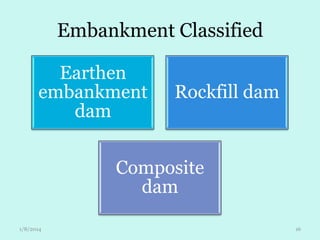

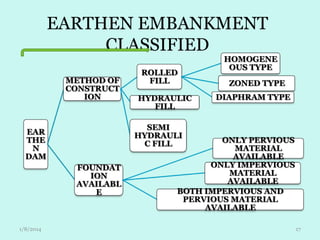

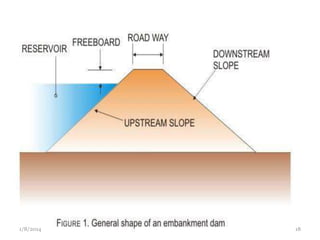

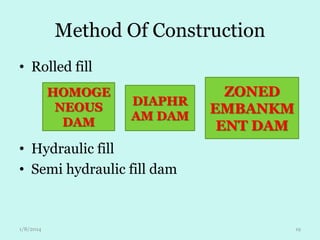

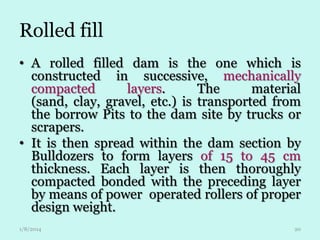

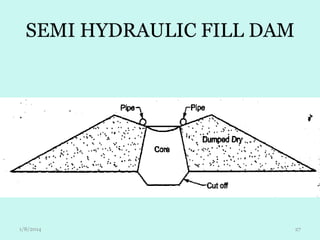

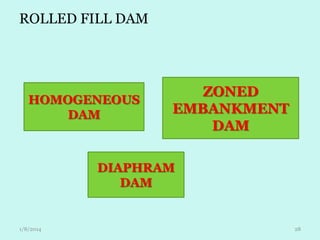

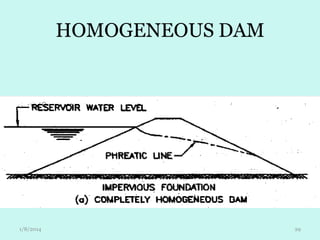

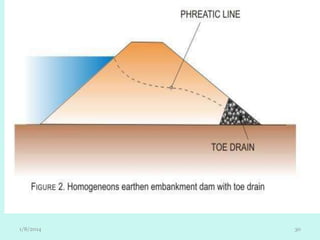

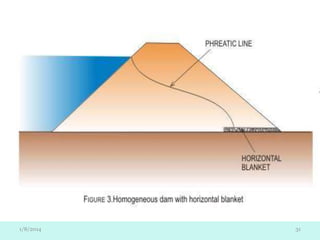

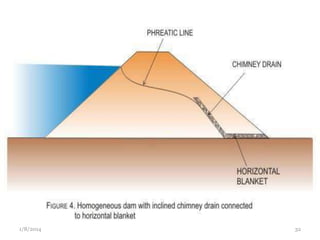

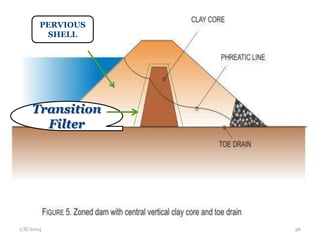

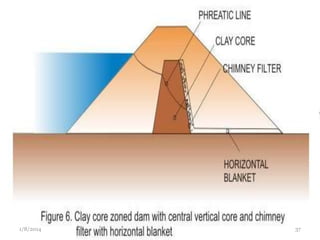

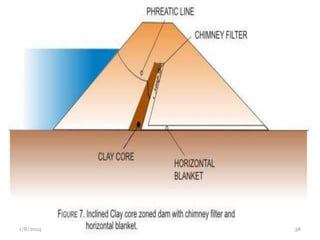

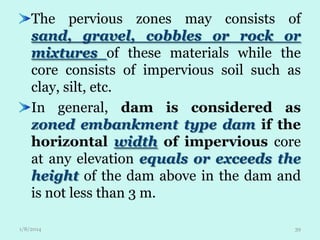

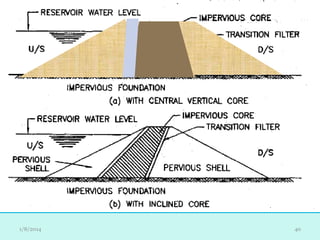

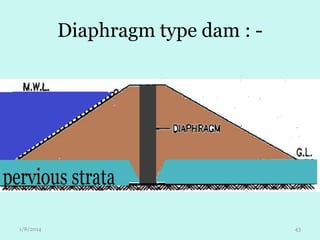

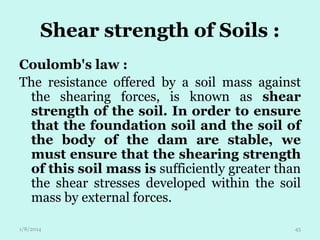

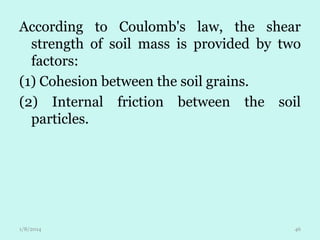

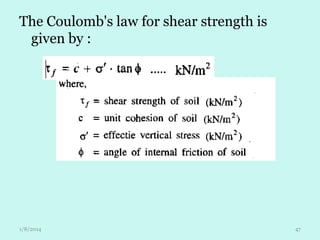

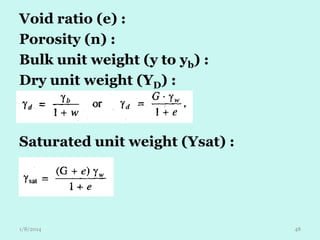

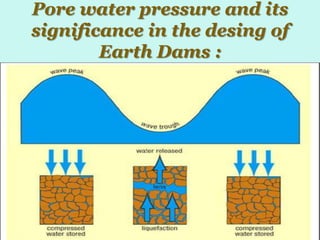

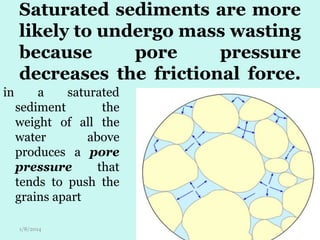

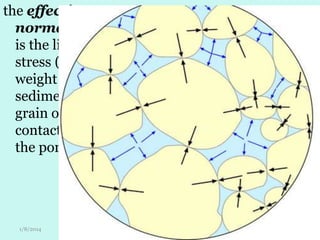

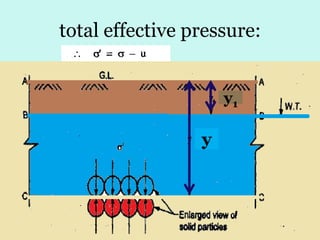

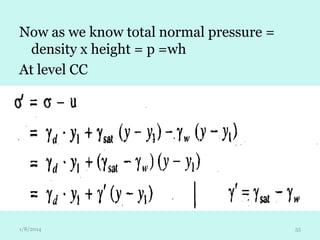

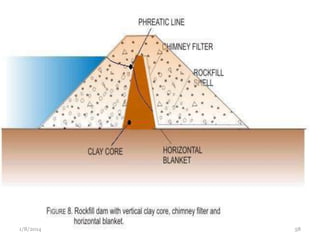

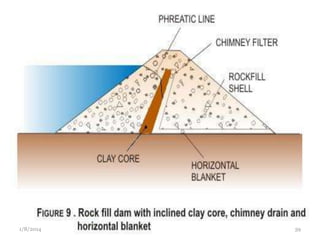

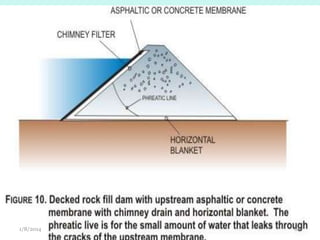

The document discusses the design of embankment dams. It defines embankment dams as dams constructed of natural materials like earth or rockfill. It describes the different types of embankment dams including homogeneous dams, zoned dams, and diaphragm dams. It also discusses important design considerations for embankment dams like controlling seepage, providing internal drainage, and ensuring the shear strength of the soil is sufficient to resist failure. Pore water pressure in saturated soils is identified as an important factor that reduces the effective stress and shear strength of soils in embankment dams.