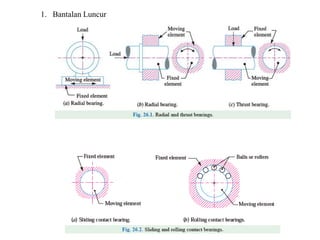

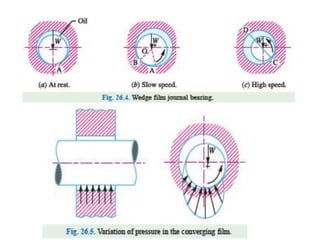

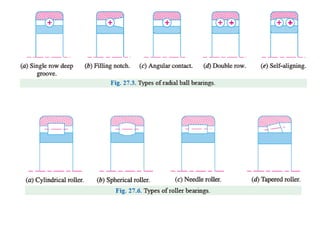

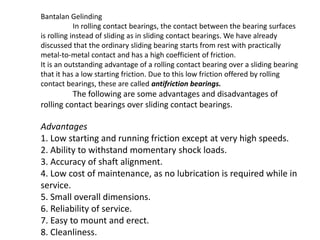

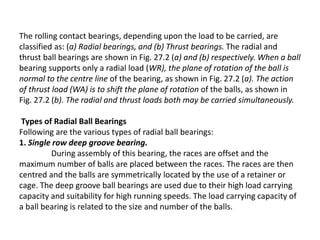

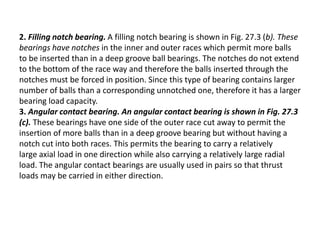

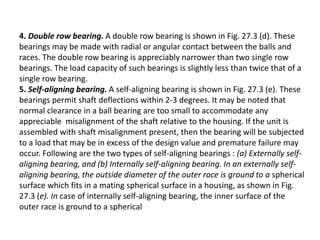

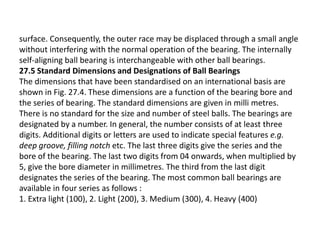

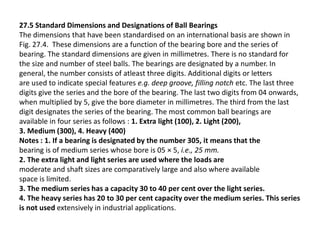

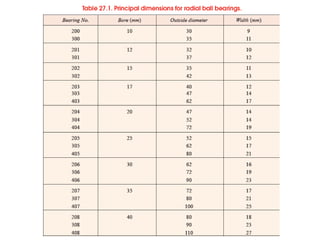

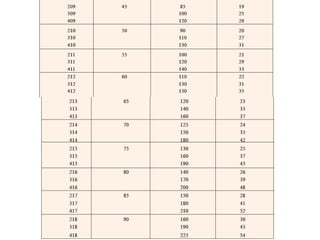

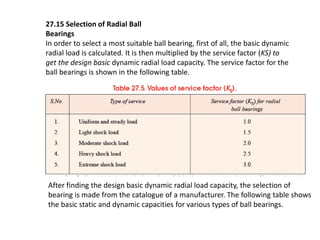

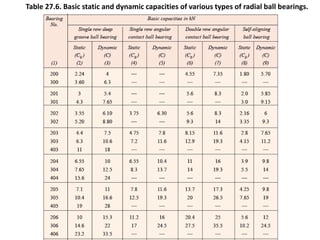

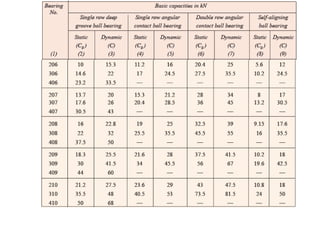

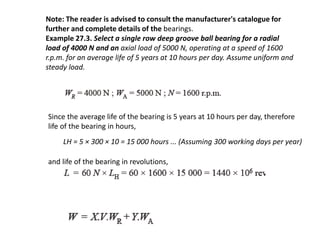

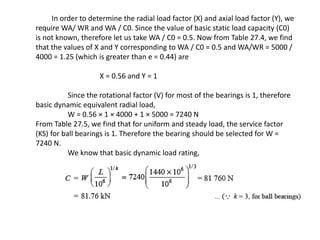

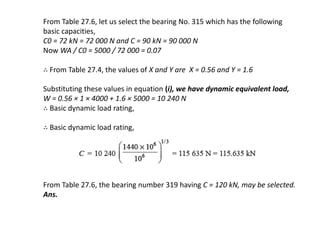

This document discusses different types of bearings used in mechanical systems. It describes sliding contact bearings and rolling contact bearings. Rolling contact bearings are further divided into ball bearings and roller bearings. The key advantages of rolling contact bearings over sliding contact bearings are their lower starting friction and operating friction, ability to withstand shock loads, and reliability. Radial bearings support radial loads while thrust bearings support axial loads. Common types of radial ball bearings are single row deep groove bearings and filling notch bearings.