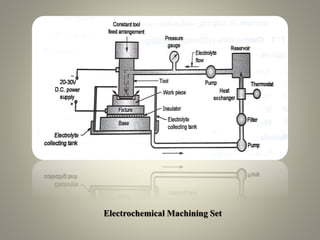

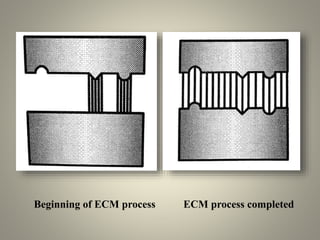

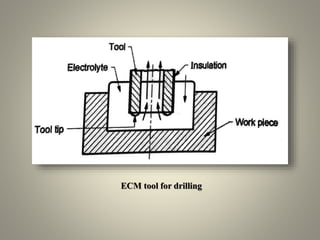

Electrochemical machining (ECM) is a deplating process that removes material from a workpiece through anodic dissolution. In ECM, a low voltage DC power supply is used to generate an electrolysis reaction between the workpiece and a cathode tool. The electrolyte carries heat and dissolved material away from the cutting zone to allow continuous material removal. As current density is highest between the closest points of the electrodes, material is eroded from the workpiece opposite peaks in the cathode tool until the workpiece takes the inverse shape of the tool. The tool design considers both the desired workpiece shape and factors like electrolyte flow and strength.