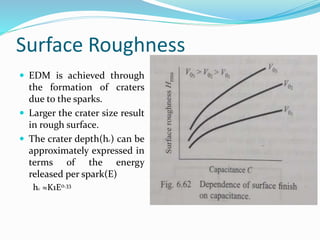

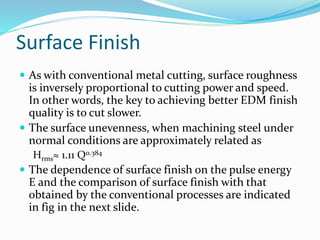

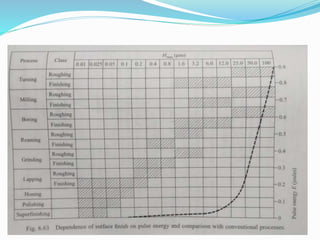

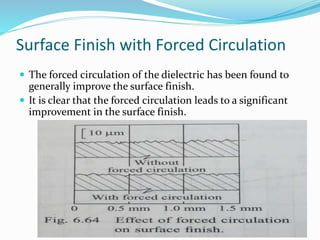

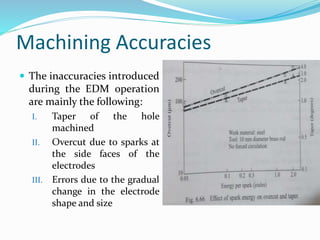

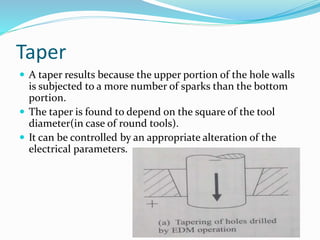

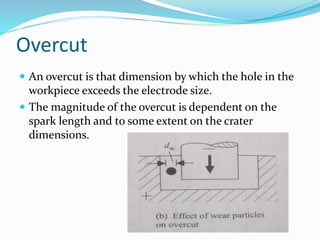

The document provides an overview of Electric Discharge Machining (EDM), an electro-thermal machining process primarily used for difficult-to-machine materials. It discusses various factors impacting surface integrity, roughness, and finish, explaining how parameters like discharge energy and pulse duration affect these outcomes. Additionally, the document addresses machining inaccuracies such as taper and overcut that arise during the EDM process.