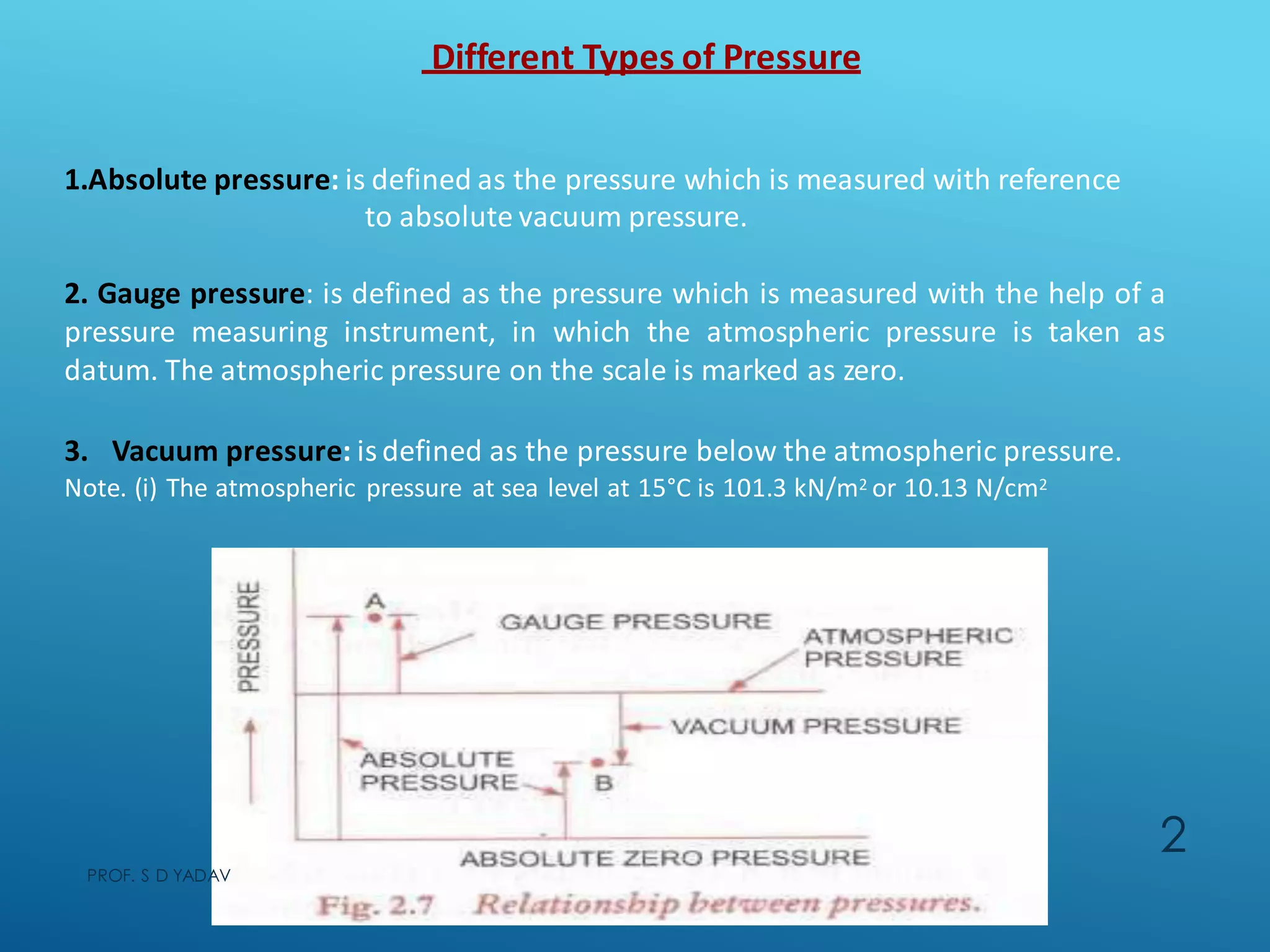

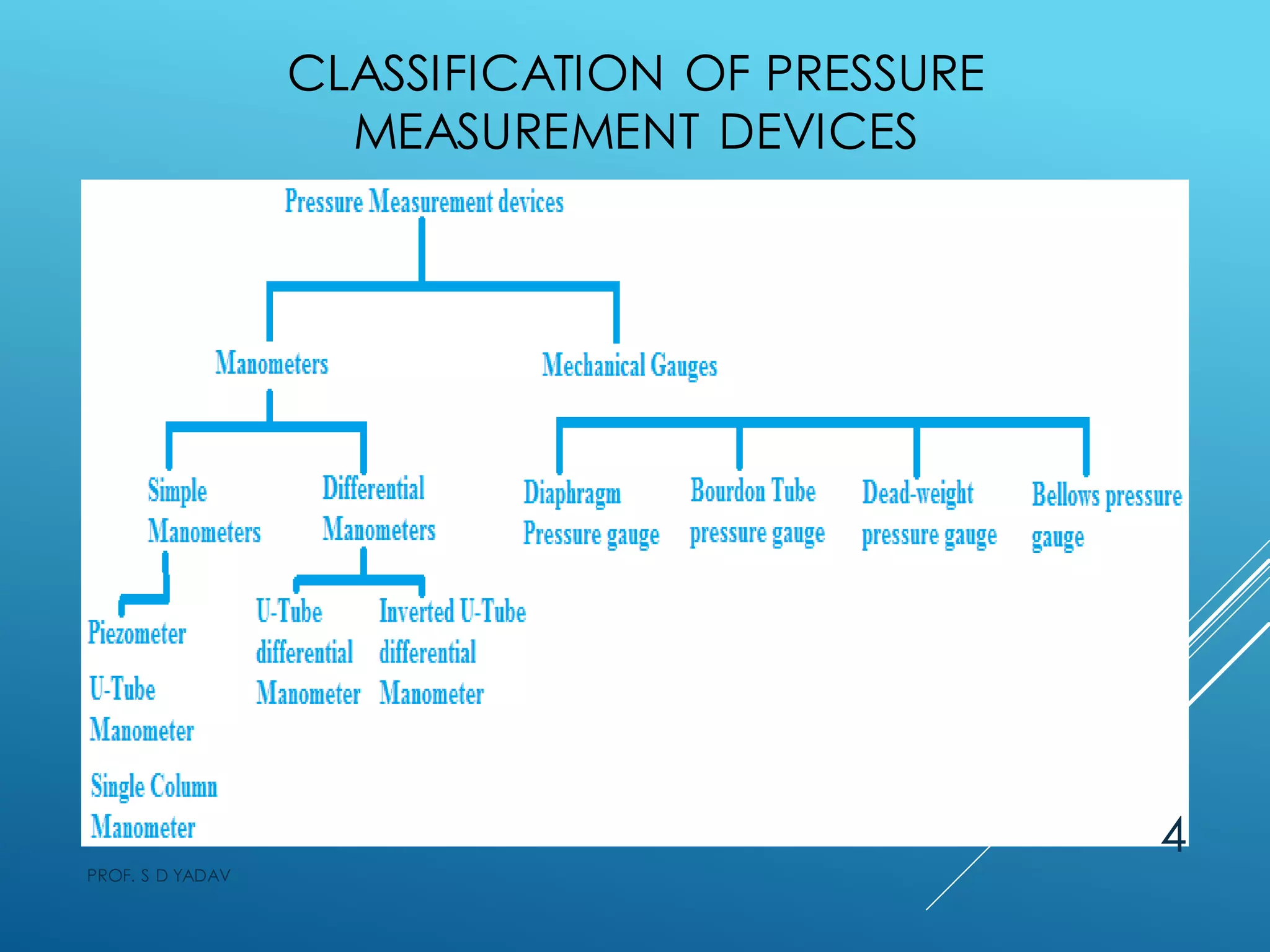

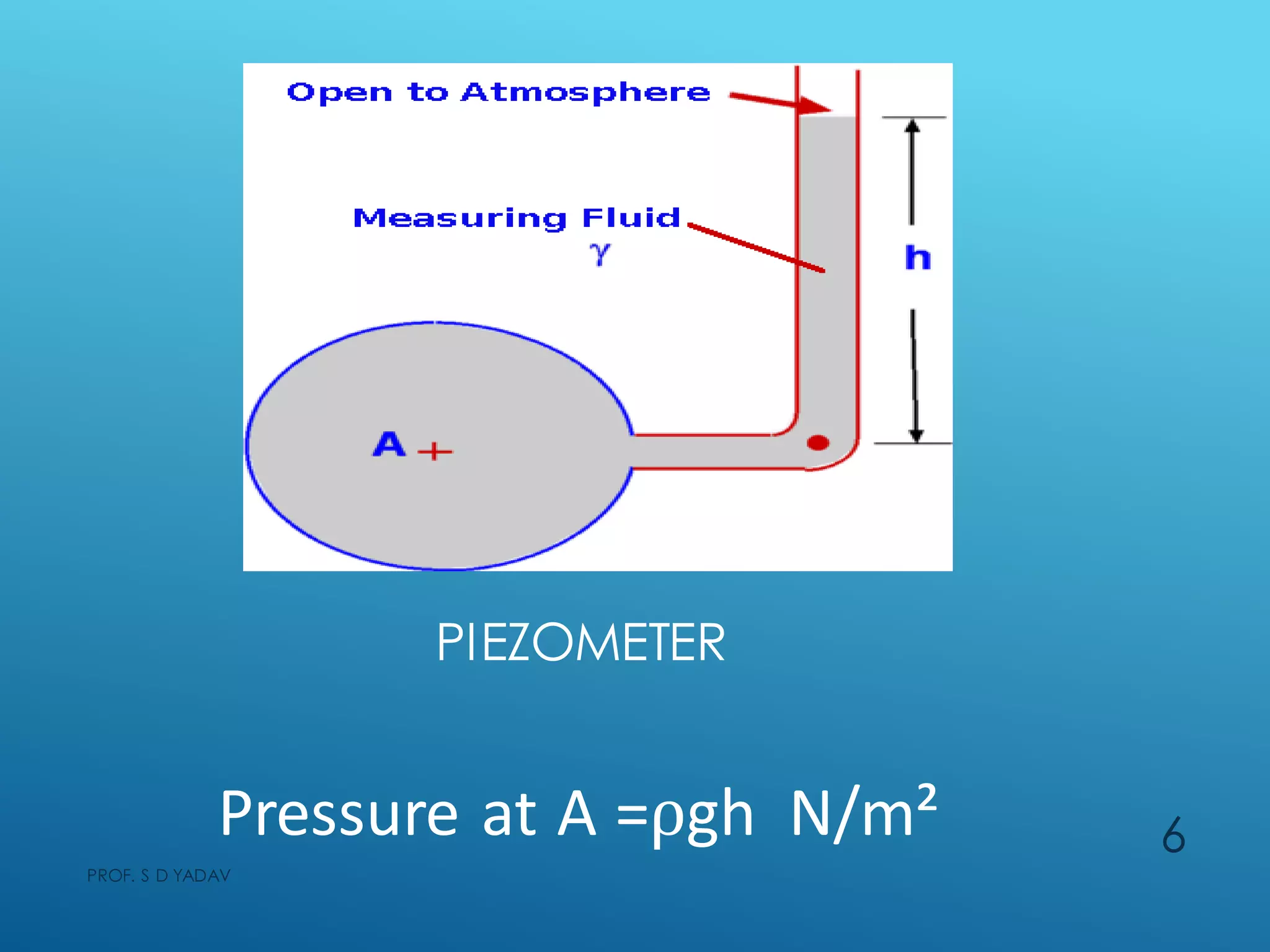

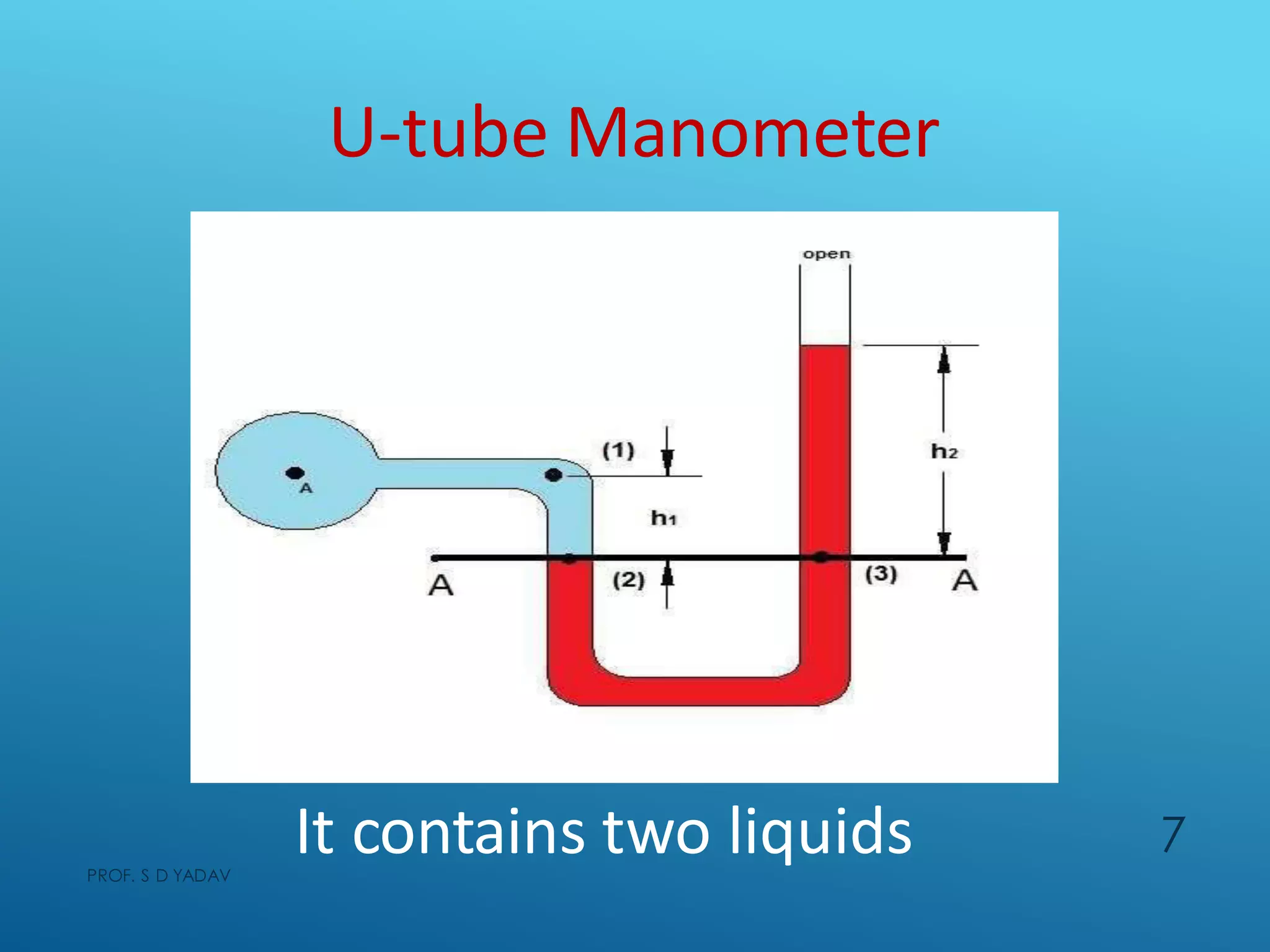

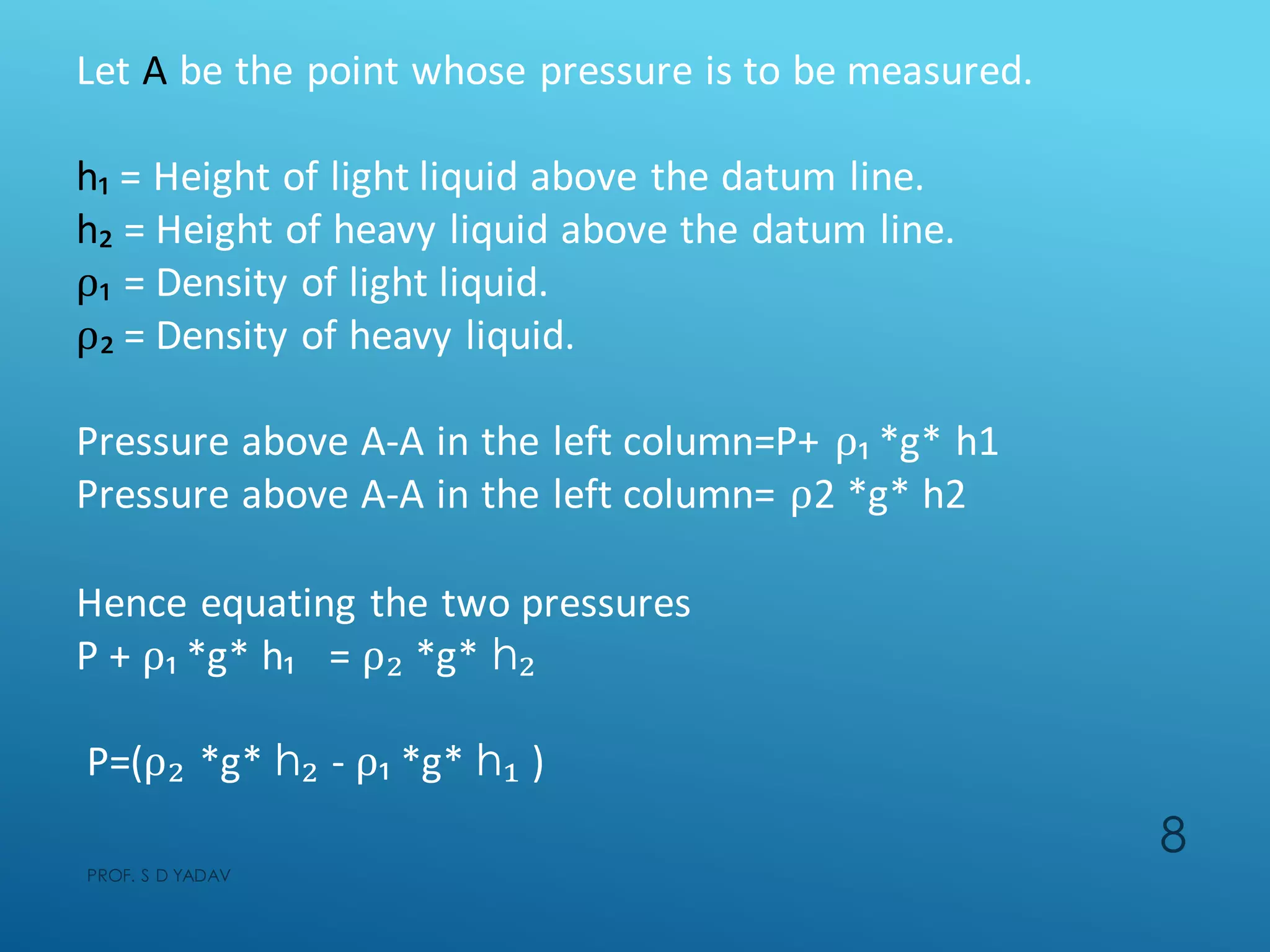

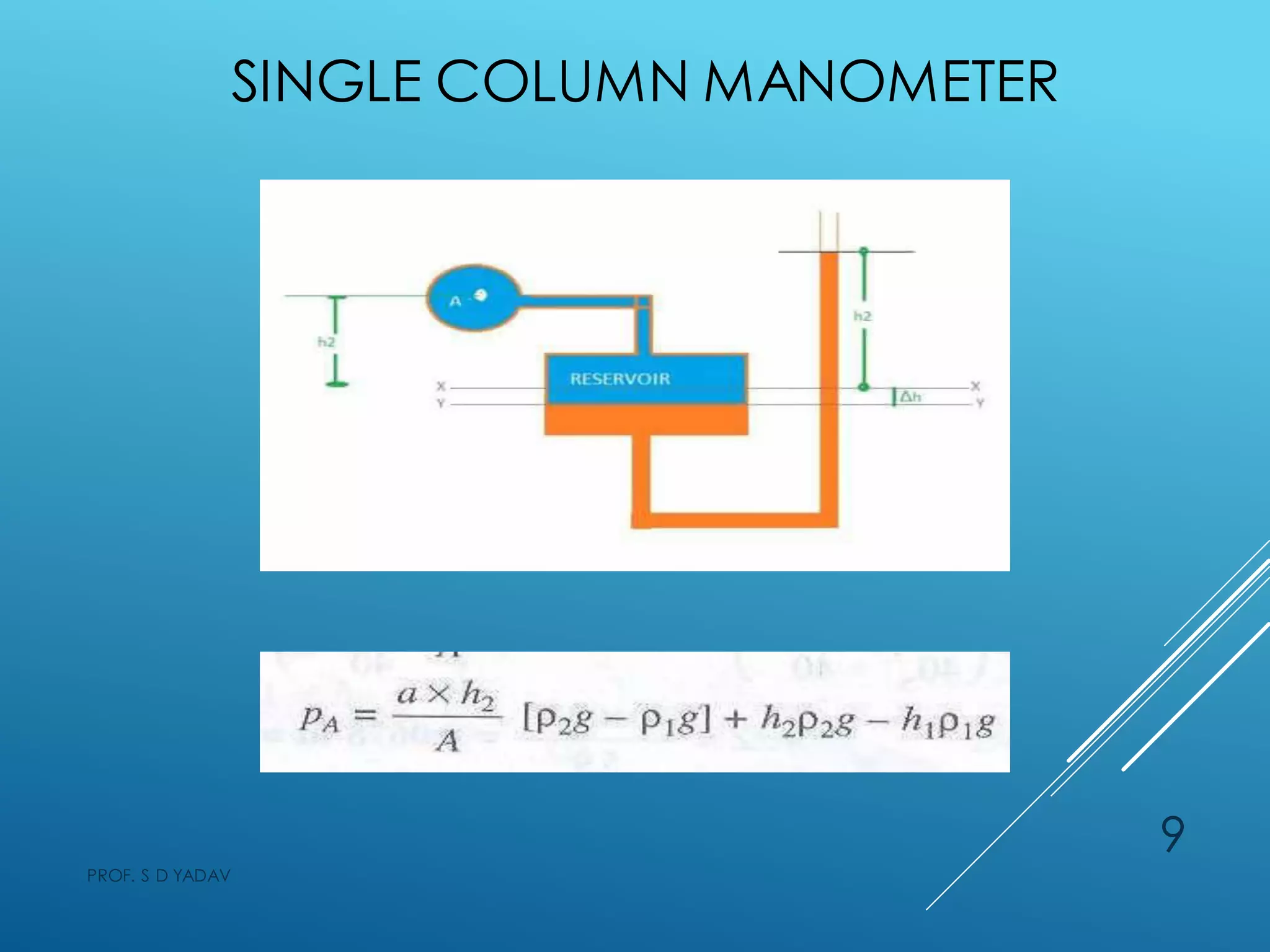

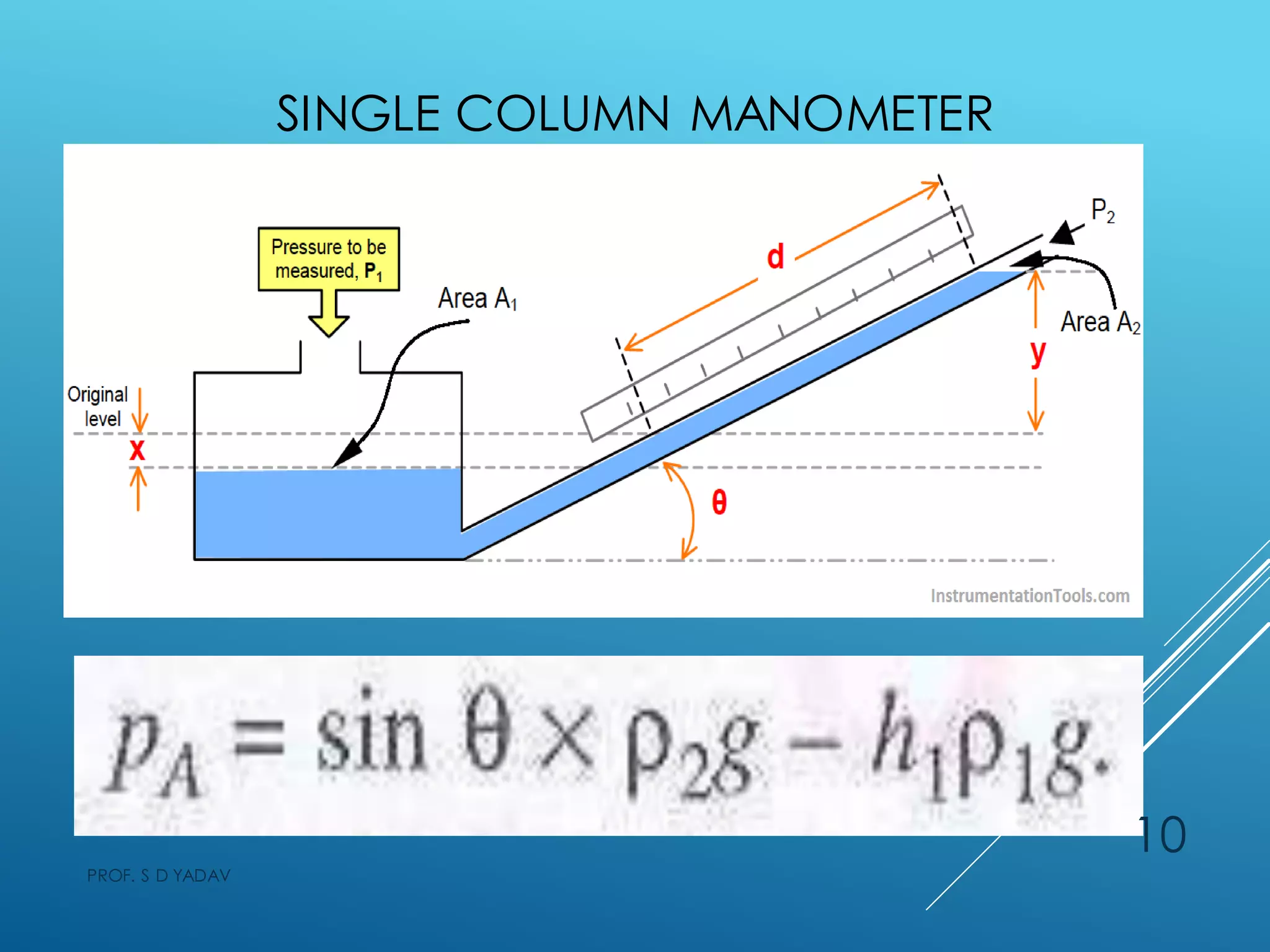

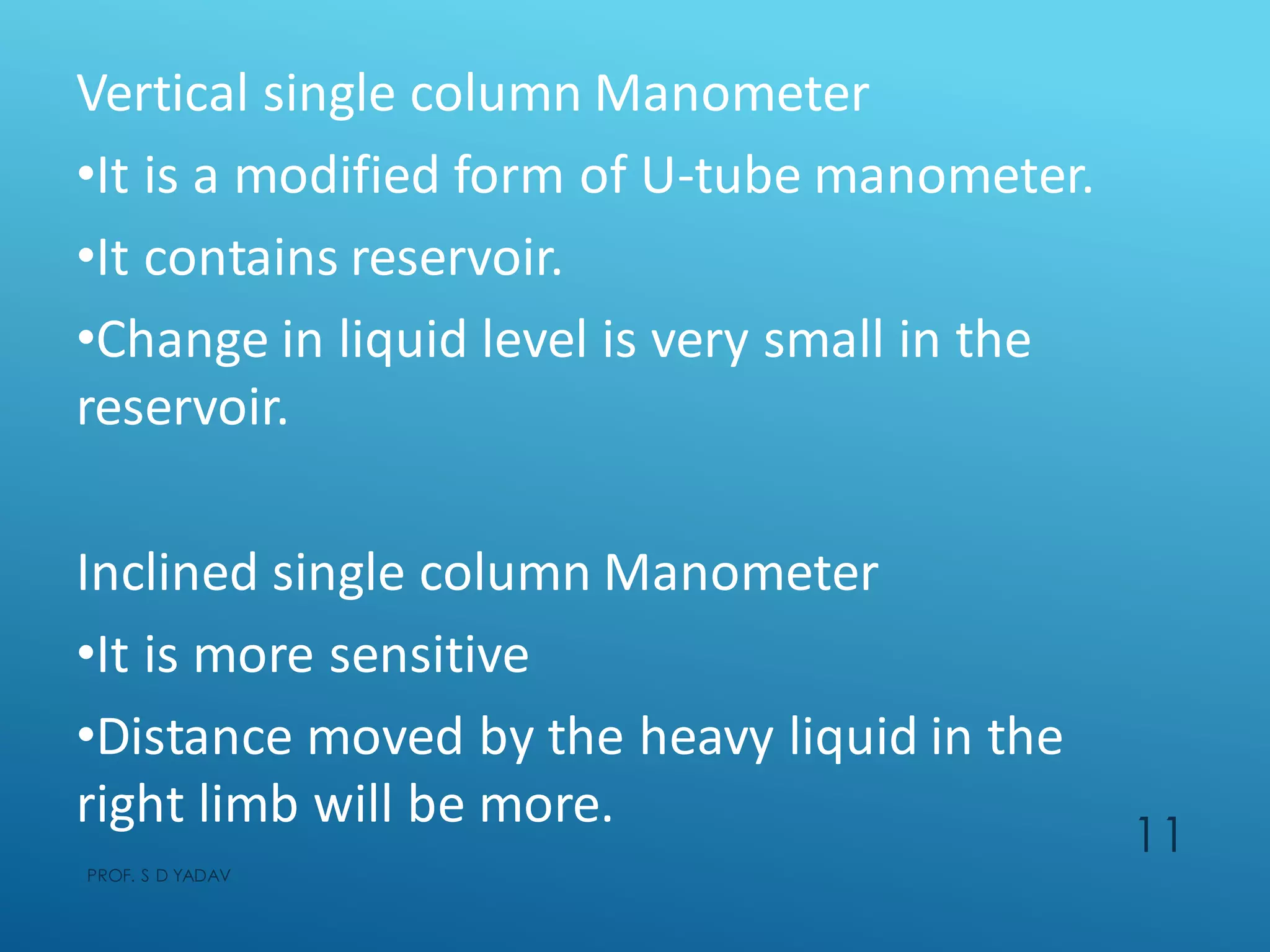

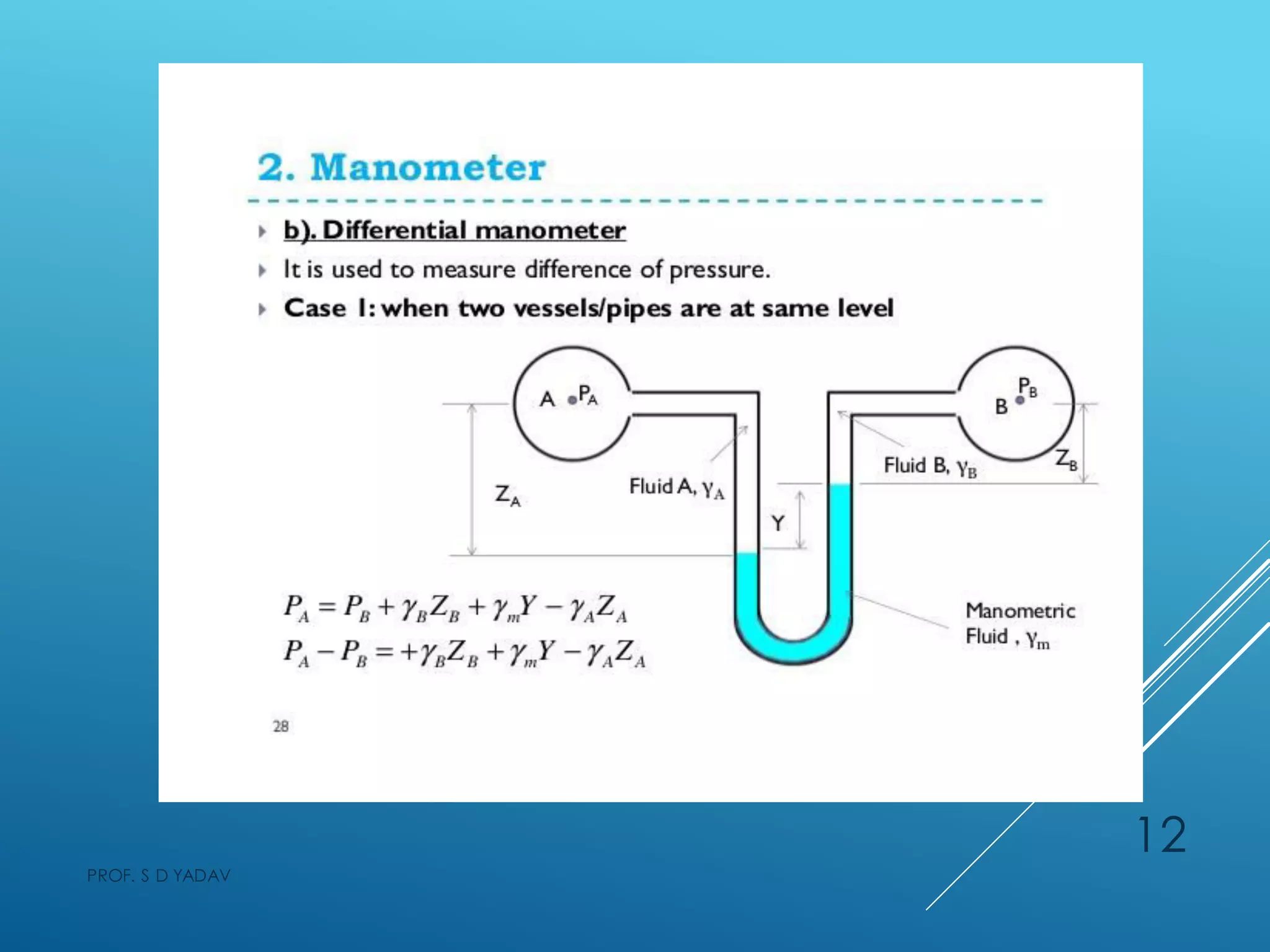

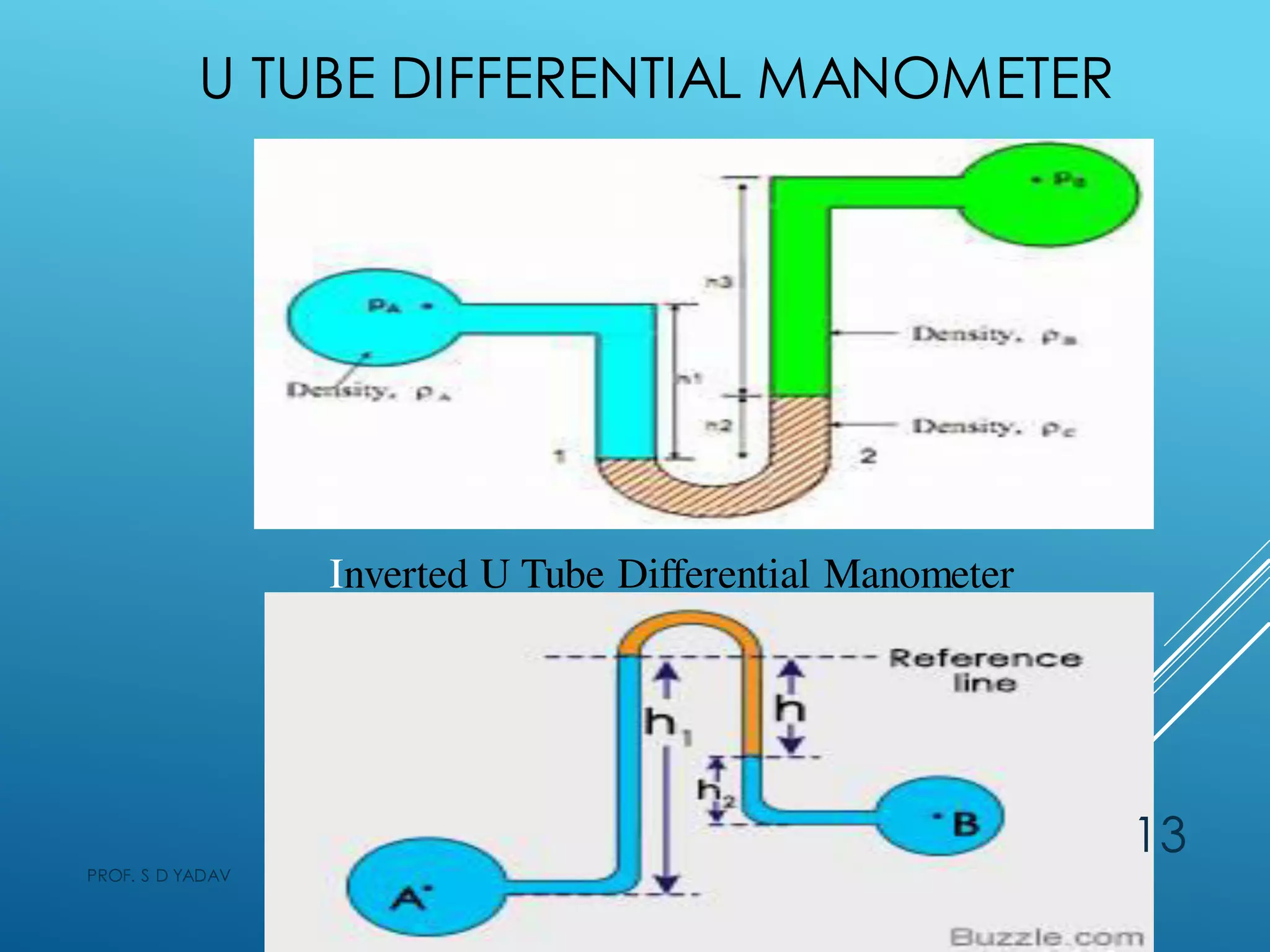

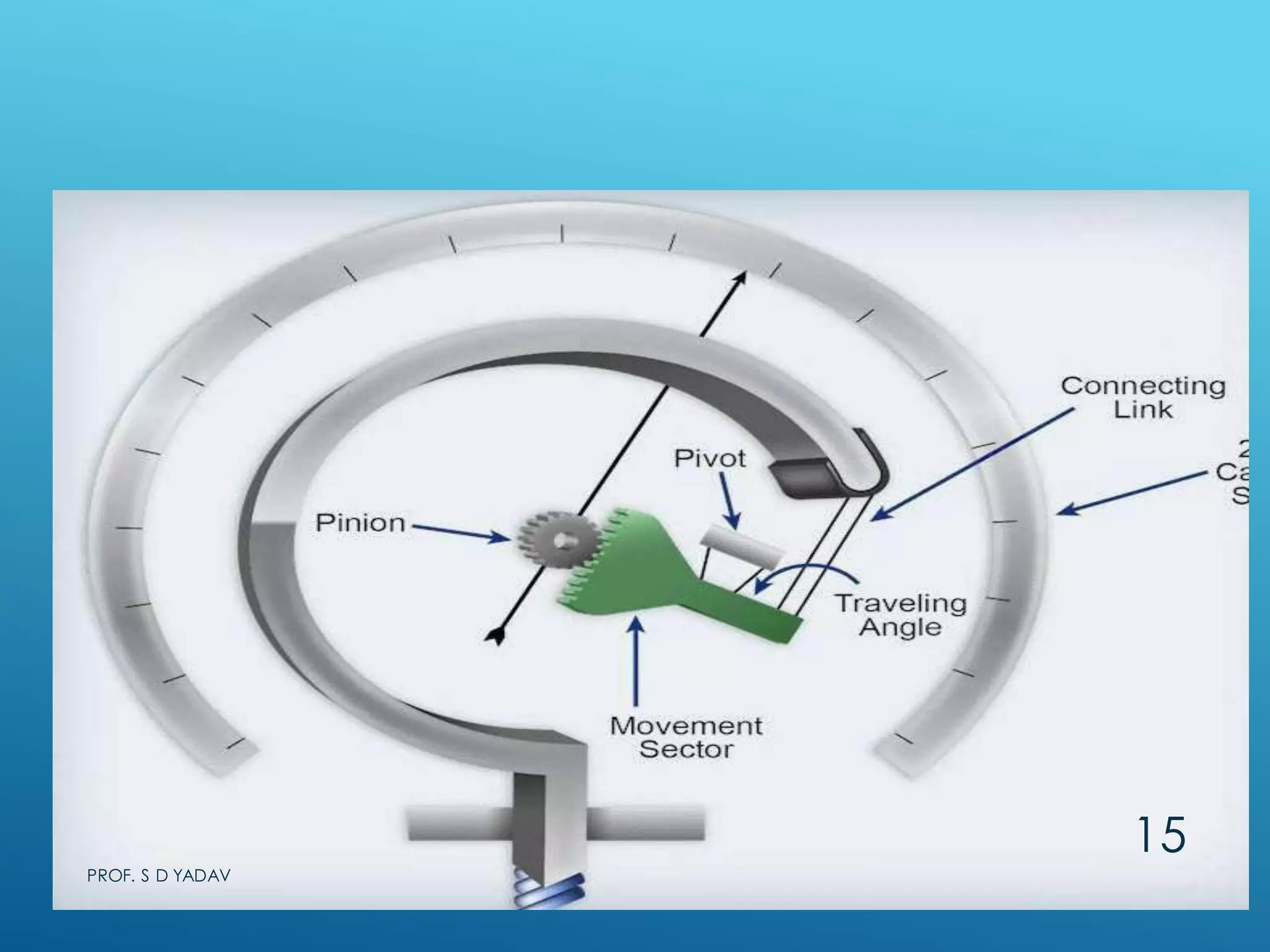

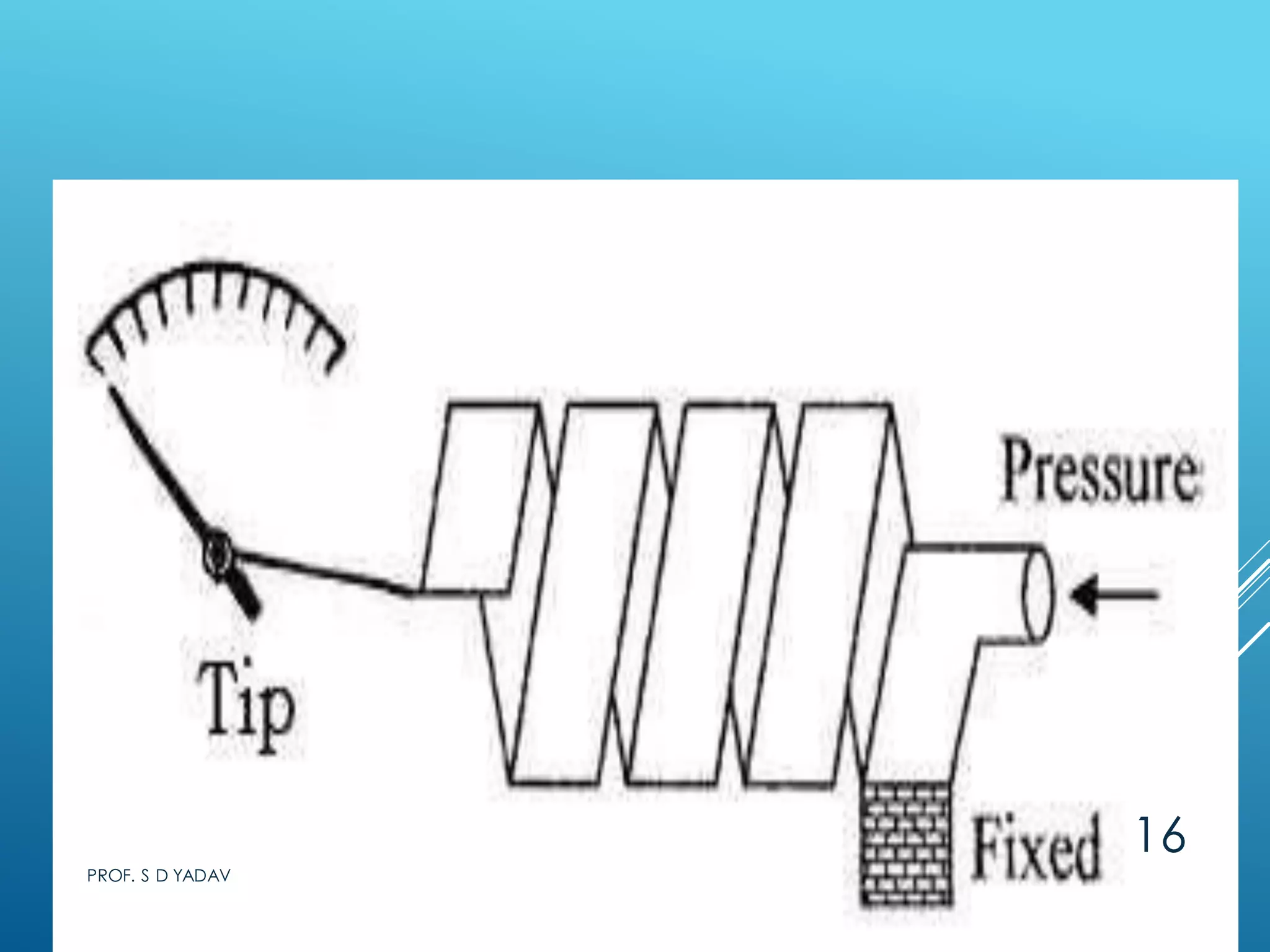

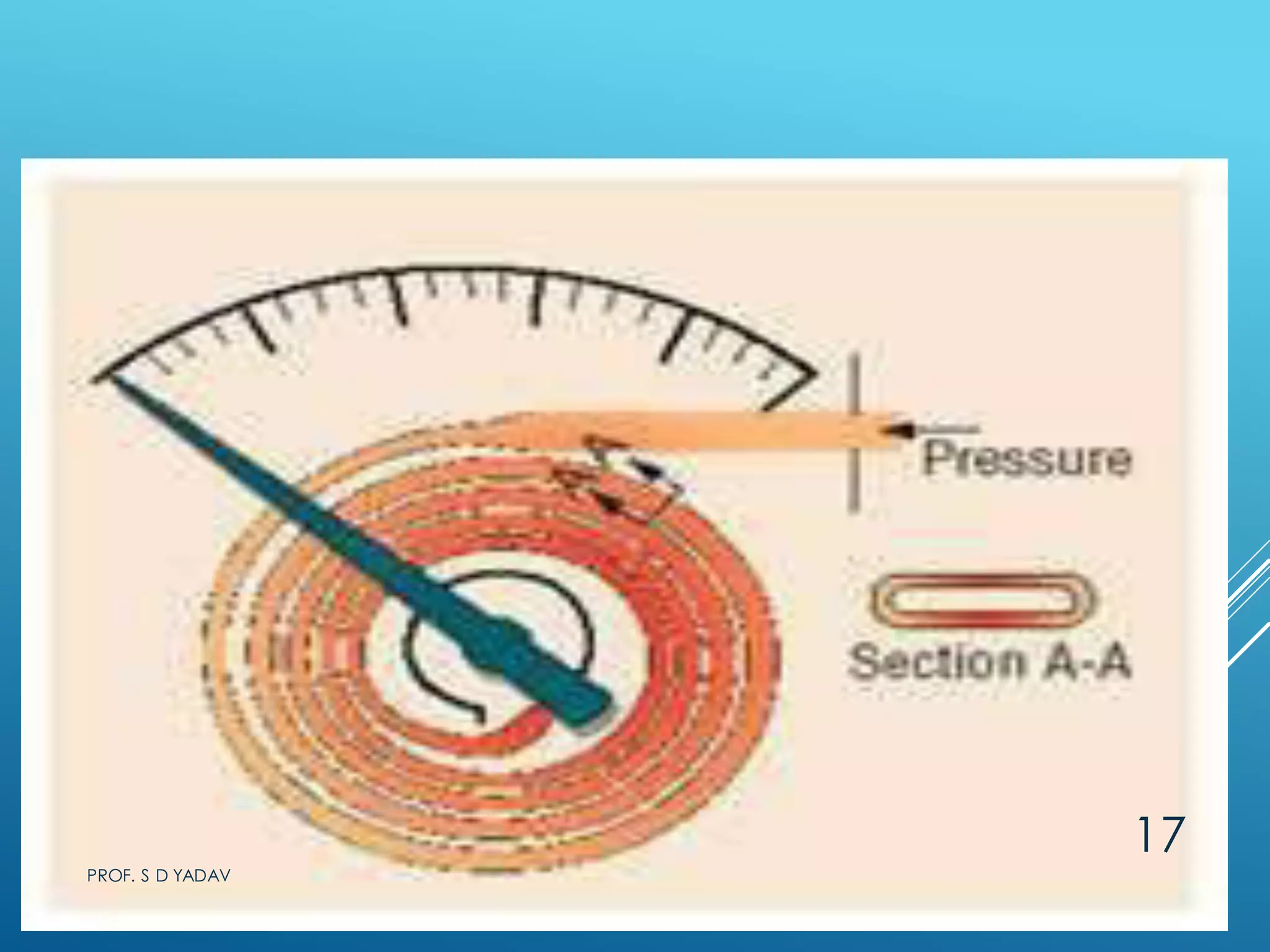

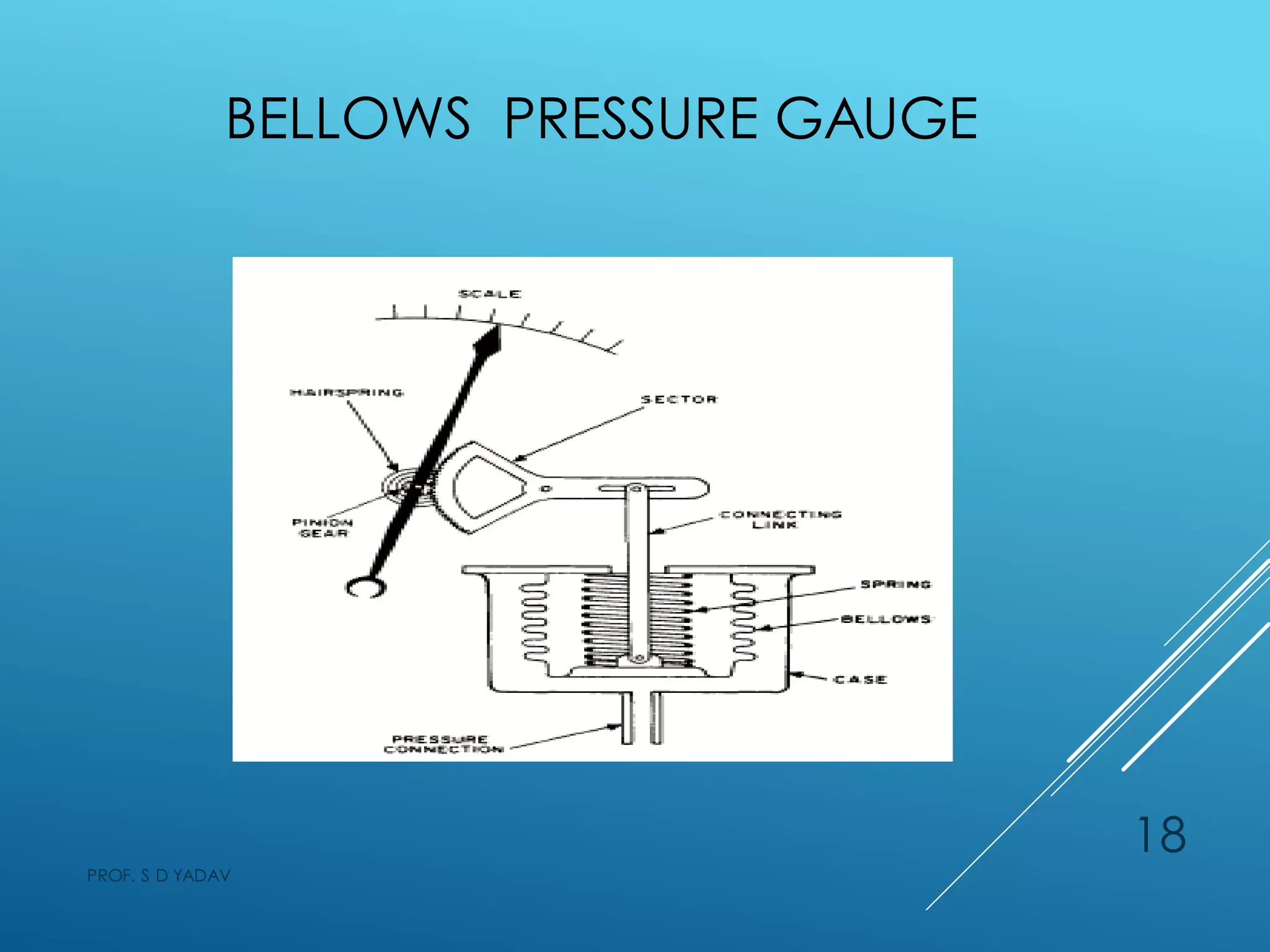

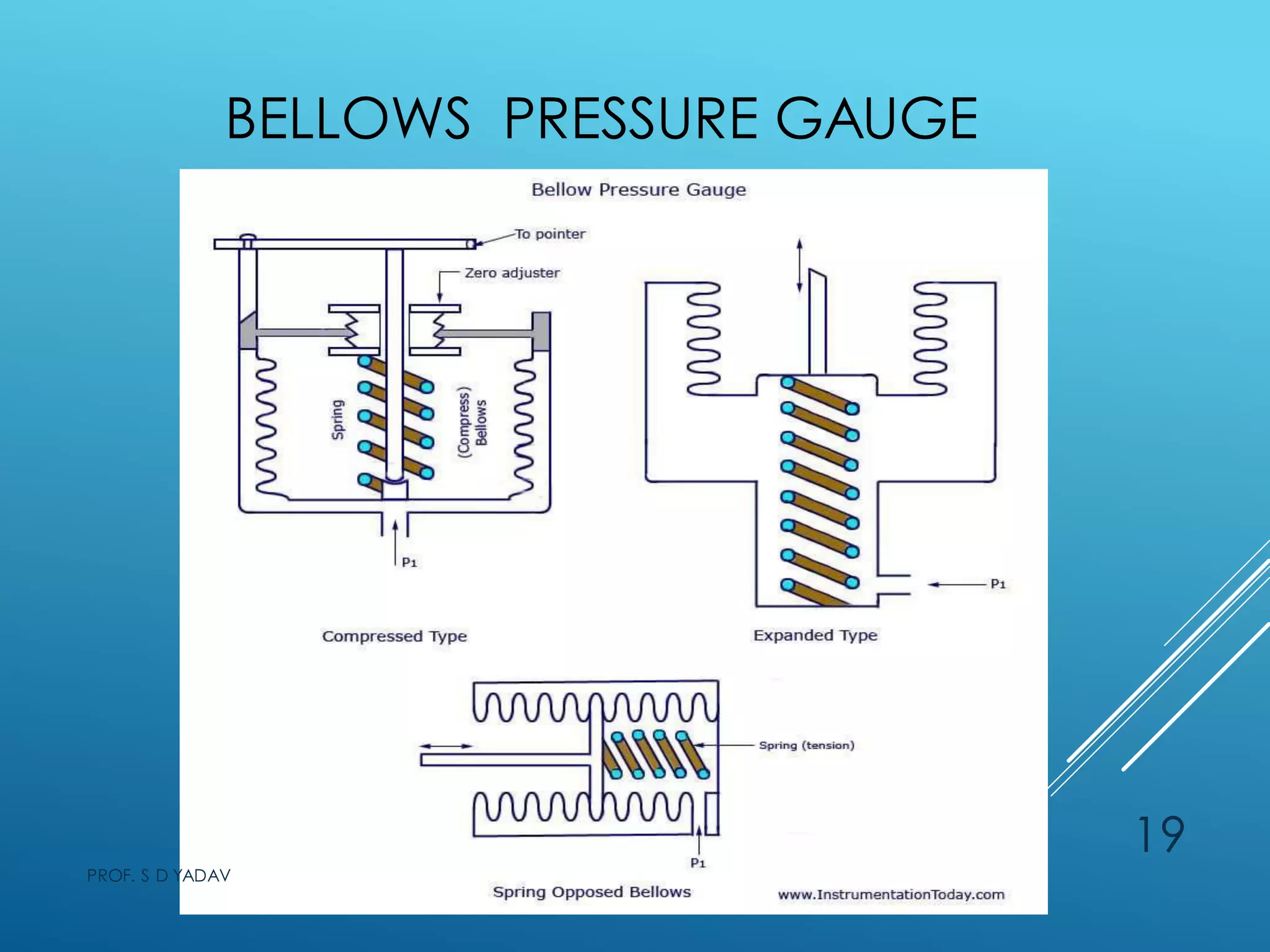

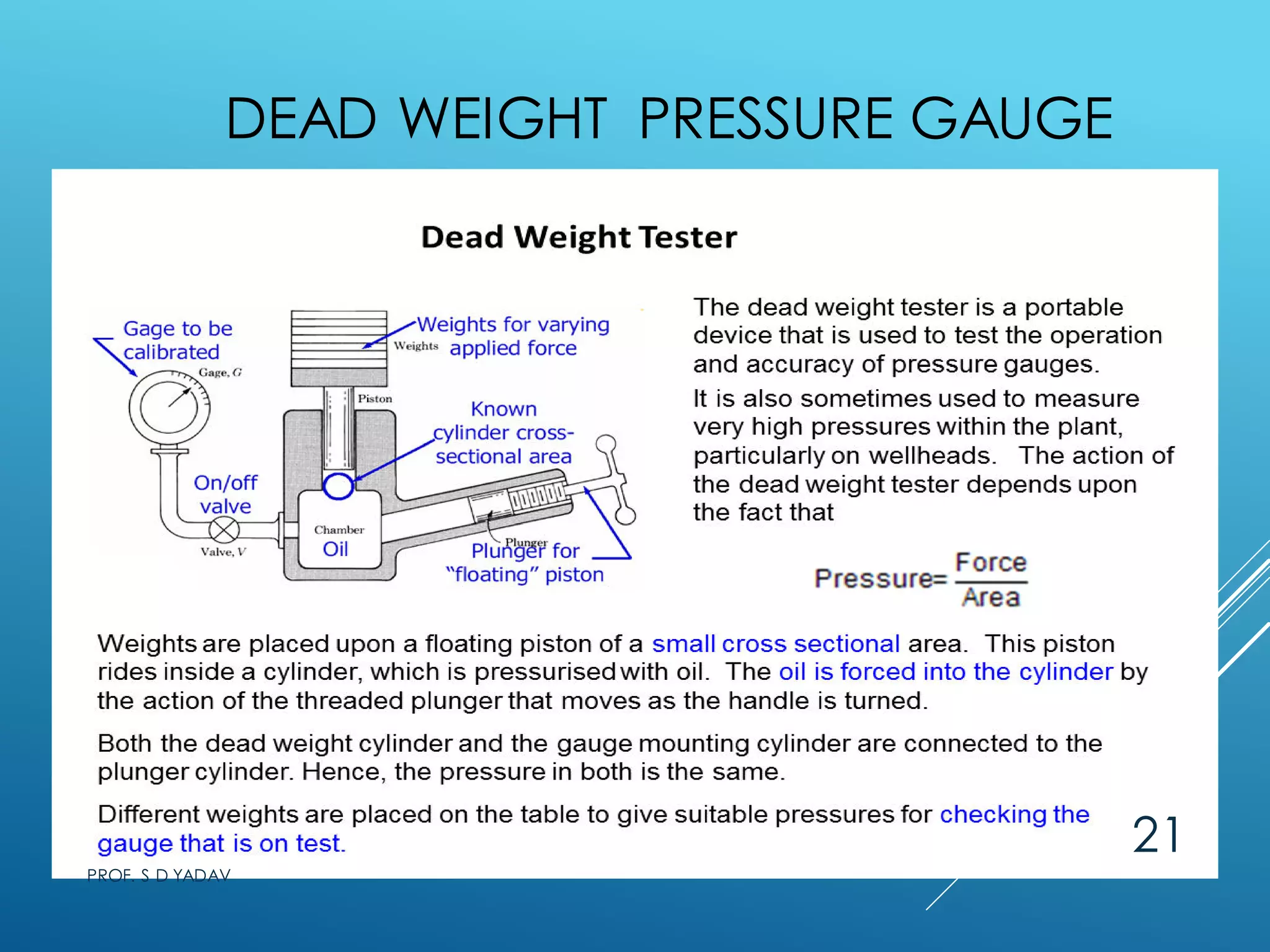

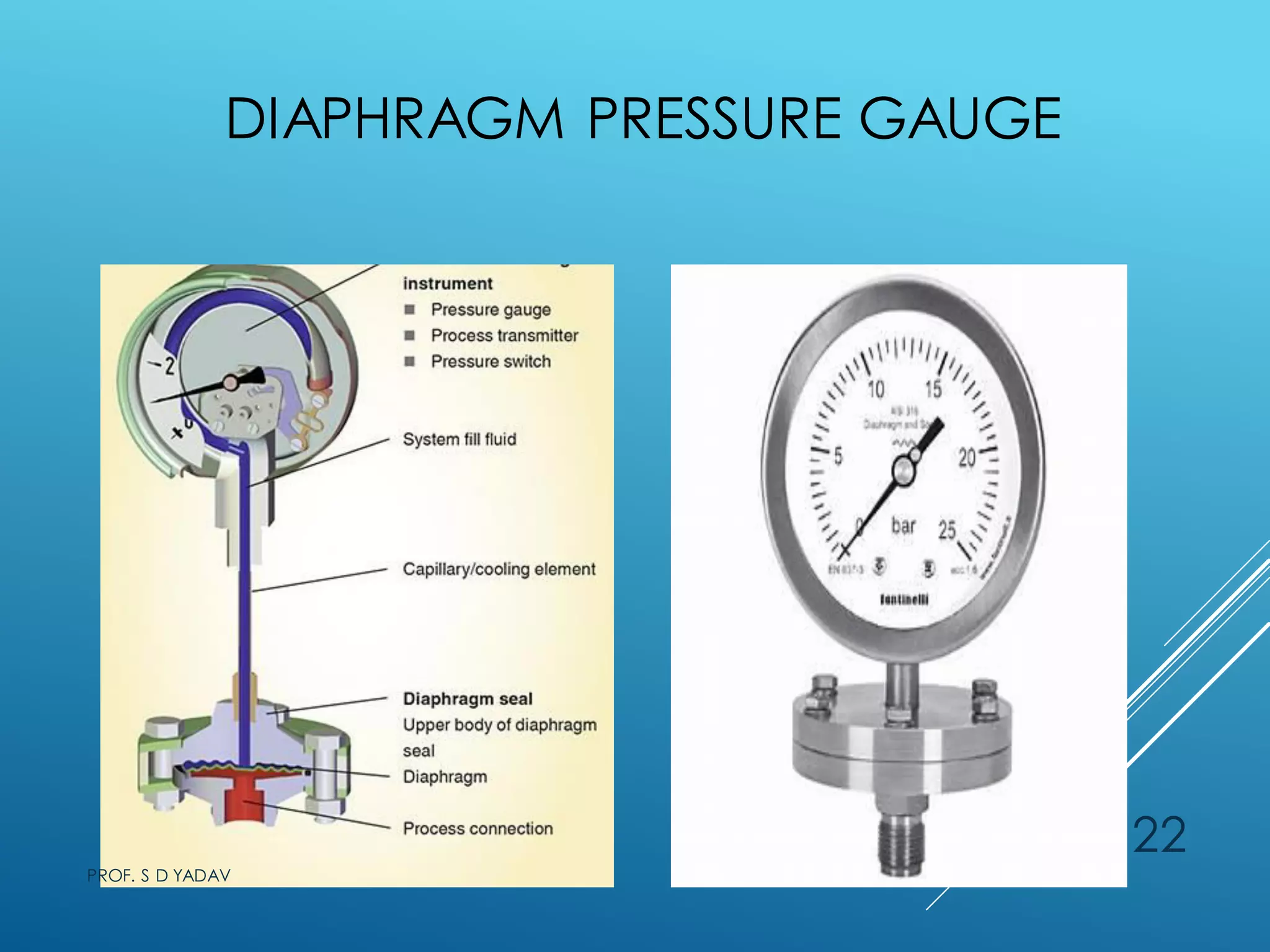

The document discusses various types of pressure measurement instruments, including absolute, gauge, and vacuum pressure. It details manometers, mechanical gauges, and their classifications, as well as specific examples like piezometers and Bourdon tube gauges. Additionally, the document highlights the operational mechanics of bellows and diaphragm pressure gauges, providing insights into their construction and application.