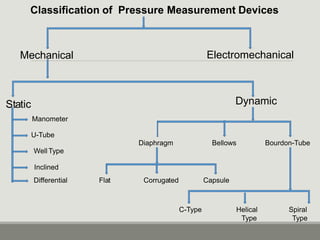

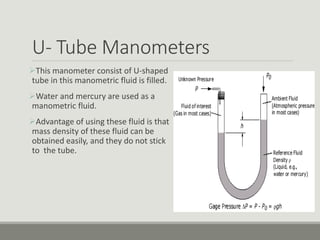

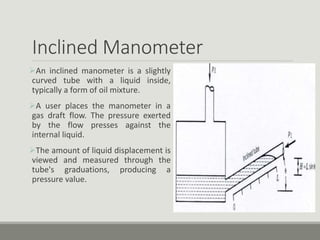

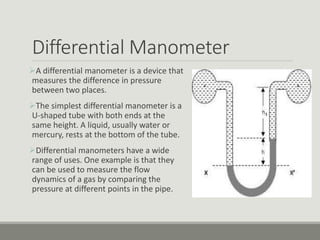

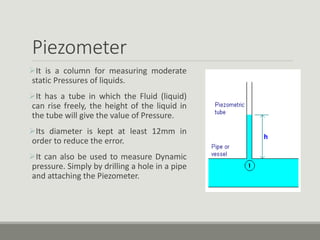

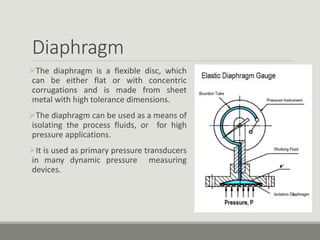

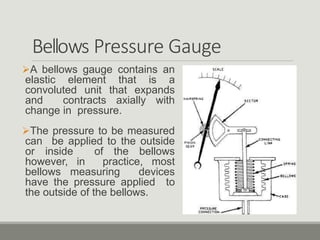

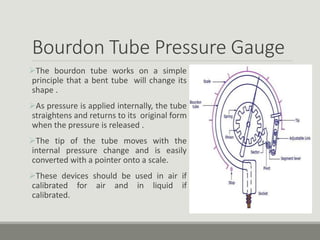

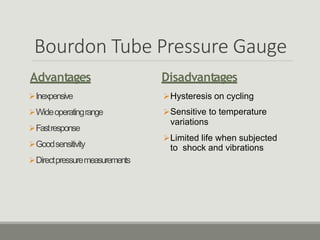

This document discusses various types of pressure measurement devices. It begins by outlining the common needs for pressure measurement: safety, process efficiency, cost savings, and measurement of other process variables. It then defines pressure and describes static and dynamic pressure. The rest of the document categorizes and describes different pressure measurement devices, including mechanical devices like manometers, piezometers, and barometers, and electromechanical devices like diaphragms, bellows, and Bourdon tubes.