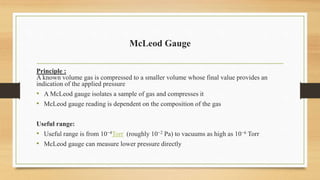

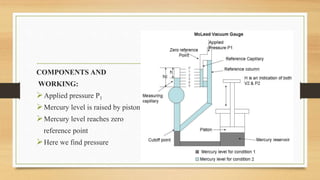

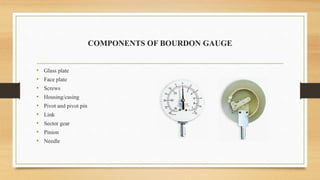

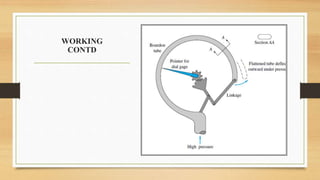

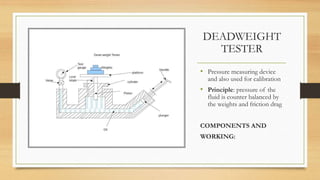

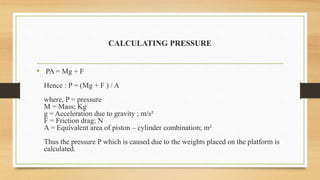

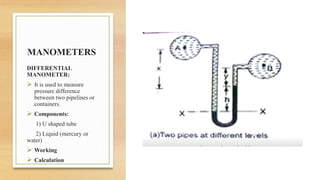

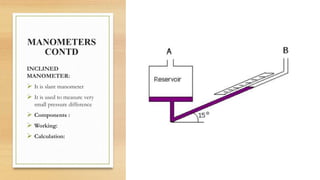

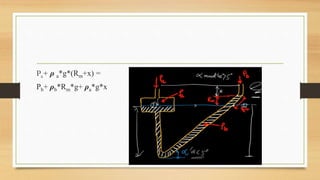

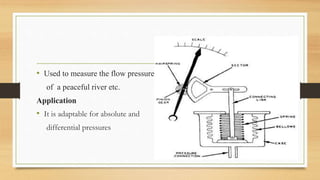

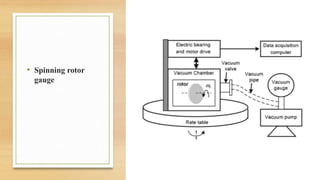

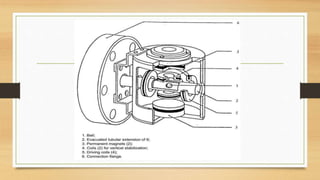

The document discusses various pressure measuring devices and their working principles. It describes McLeod gauge, Bourdon pressure gauge, piston gauge, deadweight tester, manometers, aneroid gauges, bellow pressure gauge, and spinning rotor gauge. The McLeod gauge measures very low pressures from 10-4 Torr to 10-6 Torr. The Bourdon gauge uses a coiled tube that straightens under pressure to rotate a needle. A deadweight tester precisely measures pressure by counterbalancing the fluid pressure with calibrated weights.