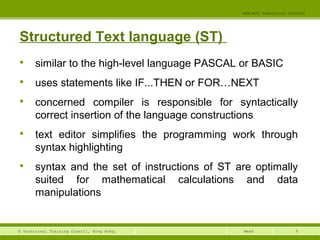

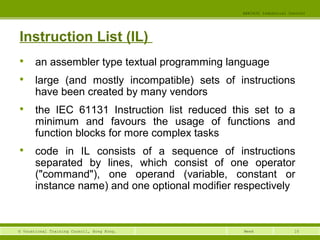

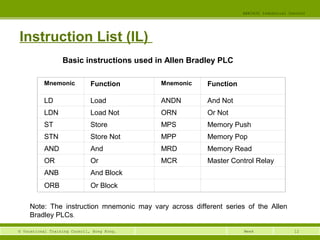

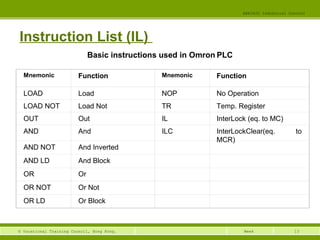

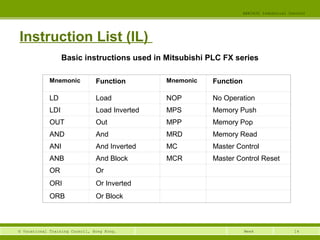

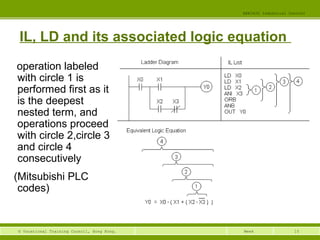

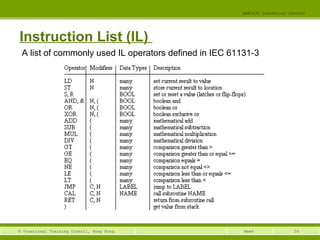

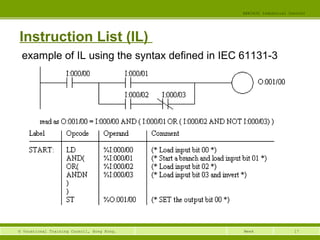

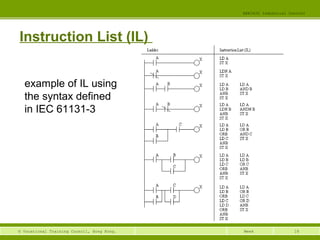

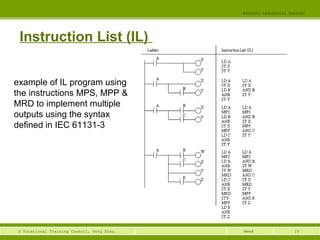

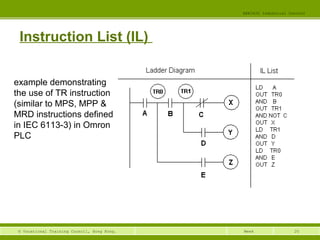

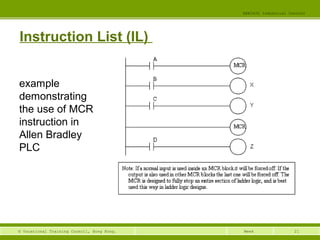

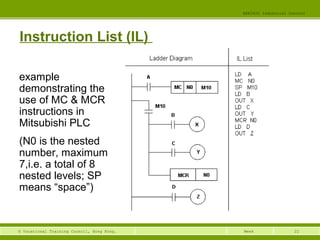

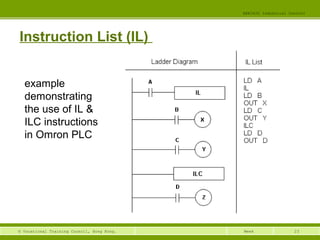

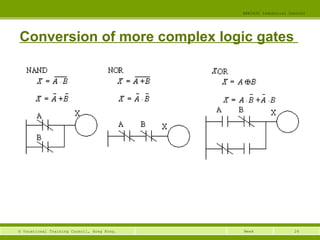

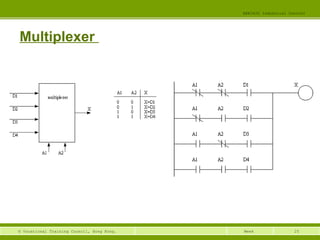

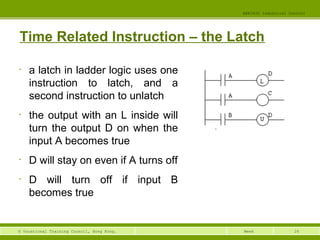

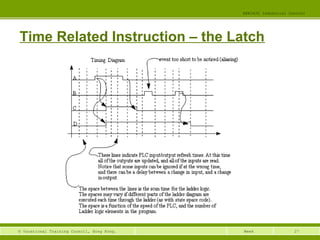

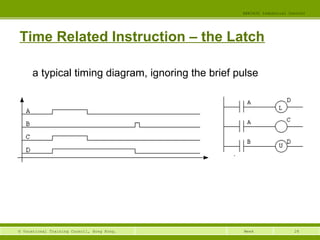

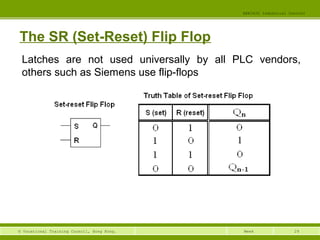

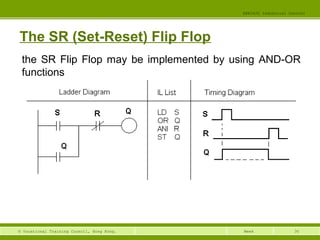

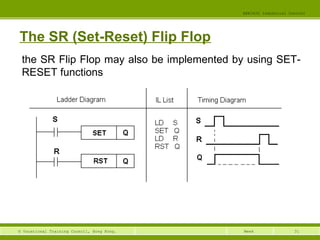

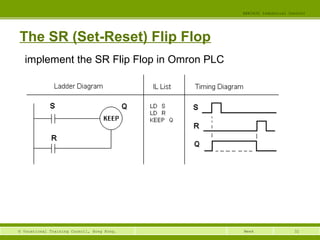

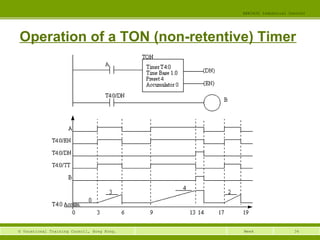

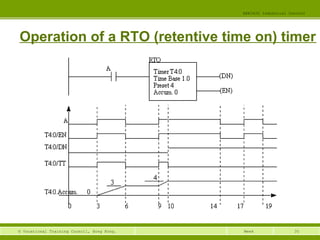

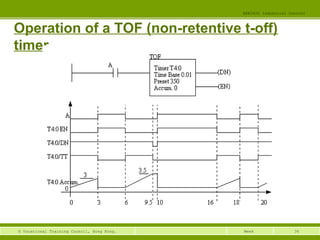

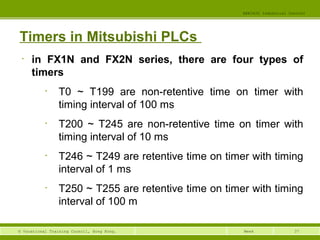

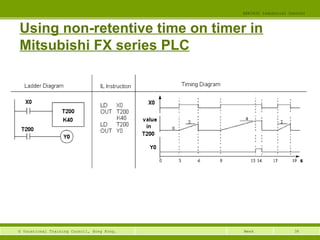

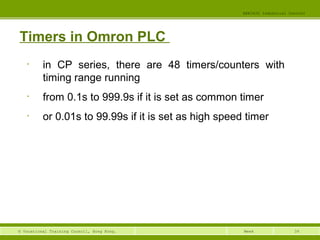

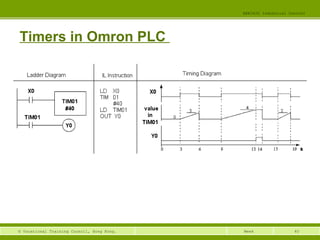

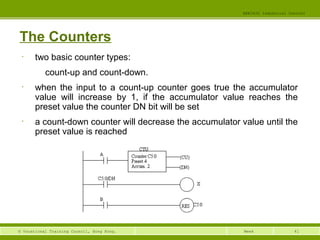

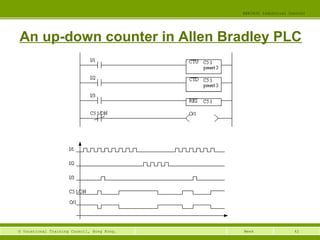

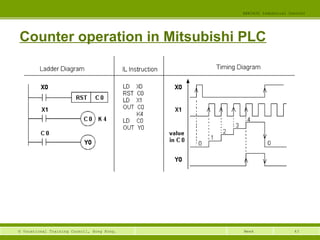

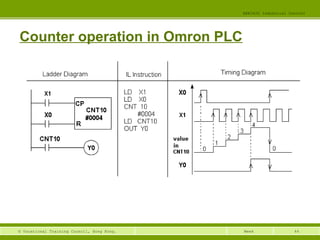

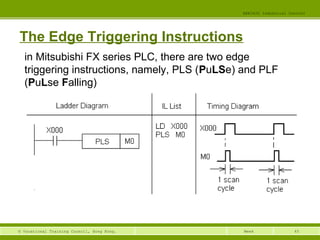

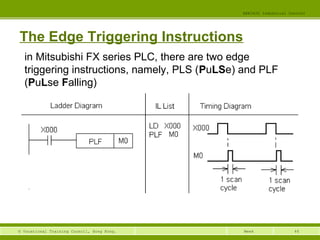

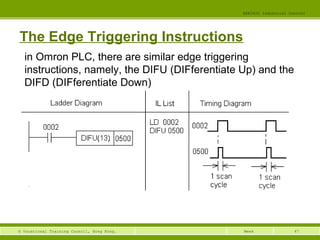

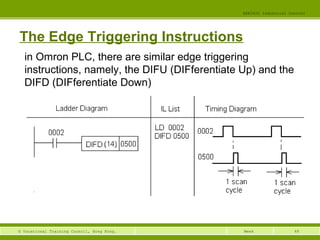

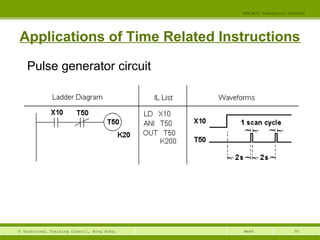

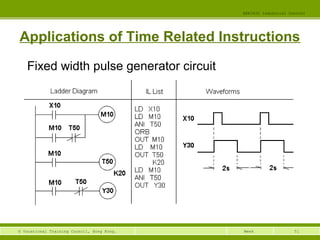

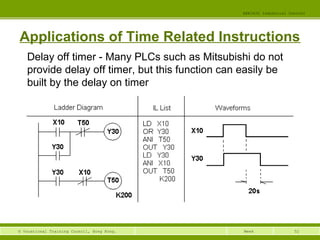

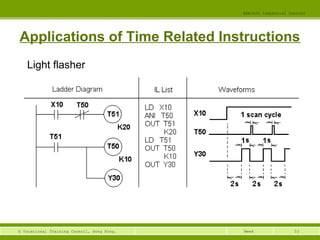

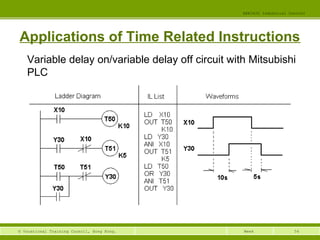

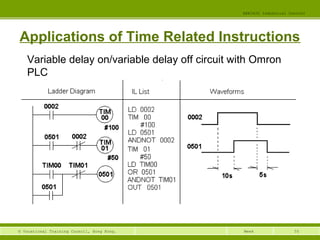

This document provides an overview of programmable logic controller (PLC) programming. It discusses the IEC 61131 standards for PLC programming languages including ladder logic, sequential function charts, function block diagrams, structured text, and instruction list. It also provides examples of programming basics like logic gates, latches, timers, and shift registers in ladder logic for different PLC brands like Allen-Bradley, Mitsubishi, and Omron.