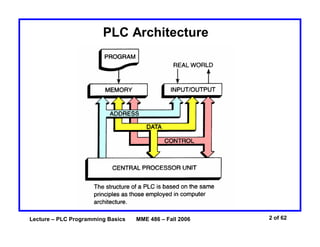

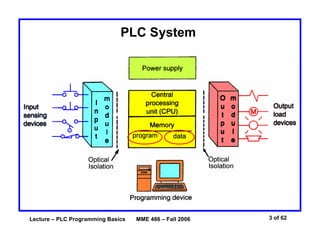

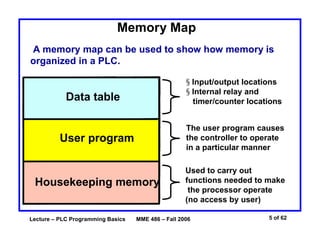

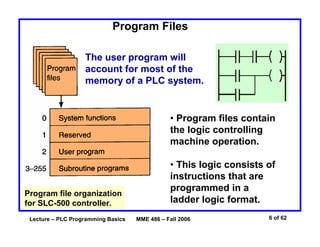

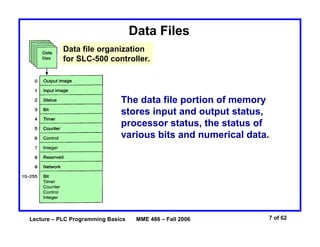

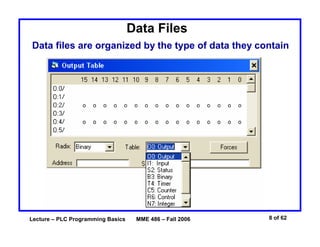

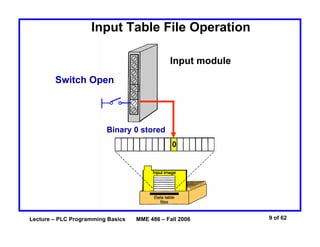

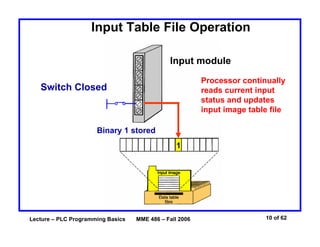

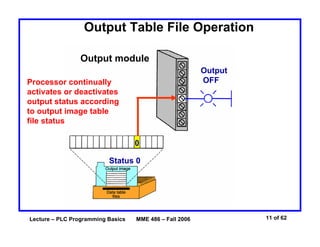

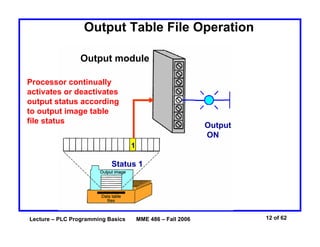

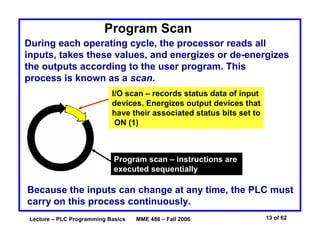

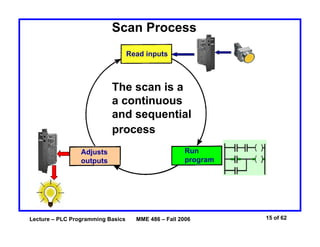

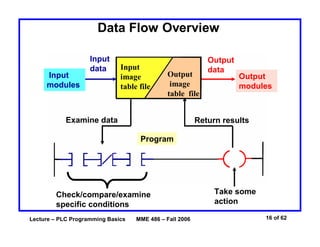

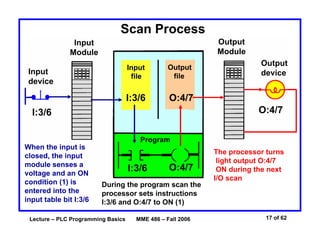

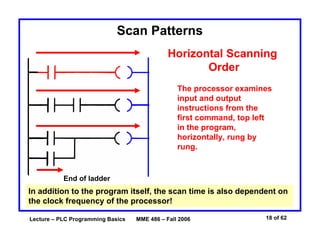

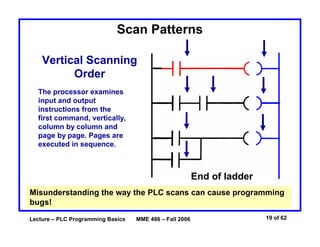

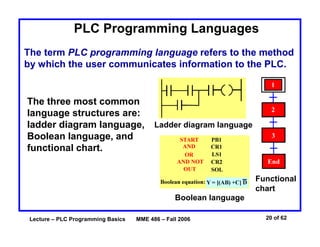

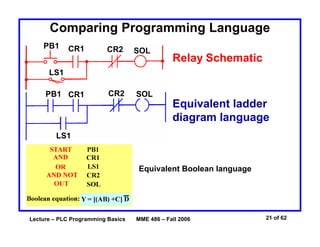

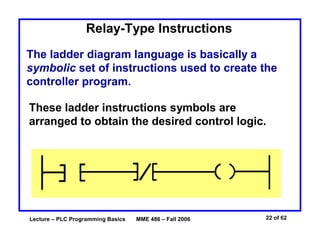

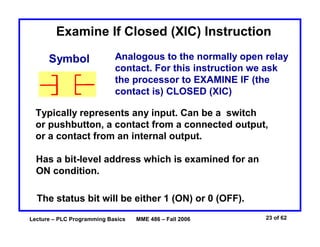

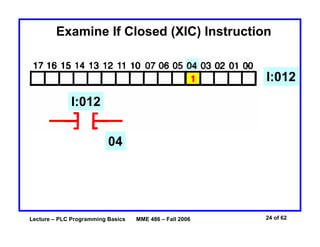

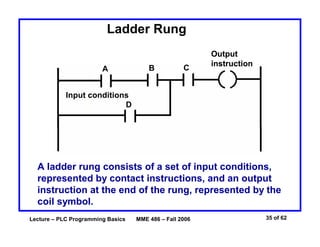

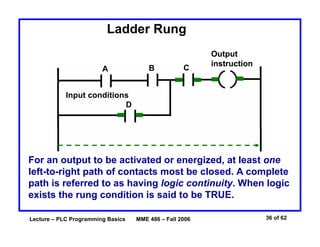

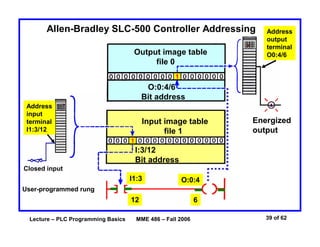

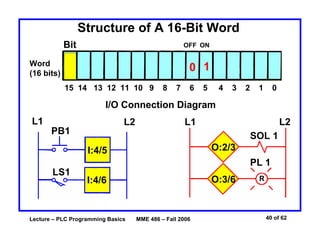

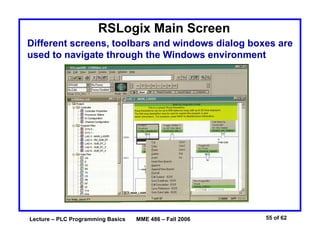

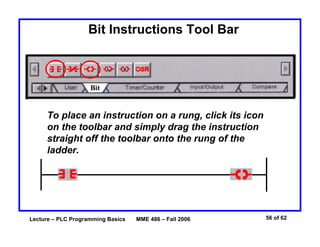

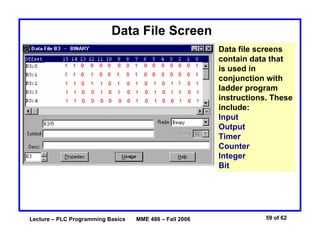

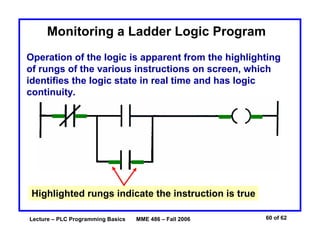

This document discusses the basics of programmable logic controller (PLC) programming and architecture. It covers topics like PLC memory organization, input/output table files, ladder logic programming, and scan processes. The key points are that PLCs use ladder logic programming which resembles relay-based logic, their memory is divided between program and data areas, and they operate by continuously scanning inputs, running the user program, and updating outputs.