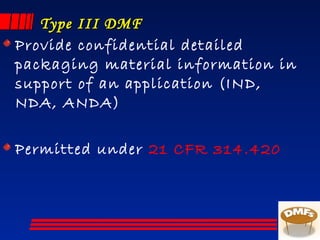

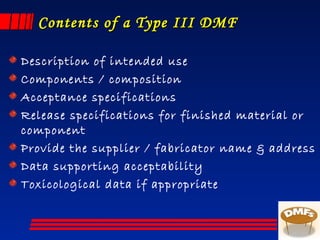

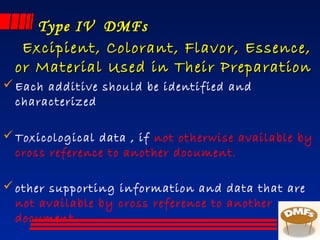

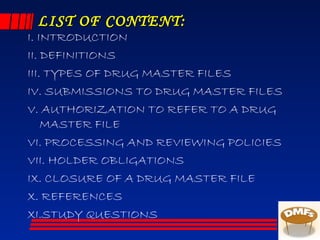

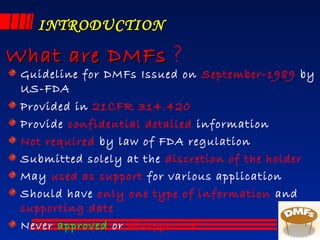

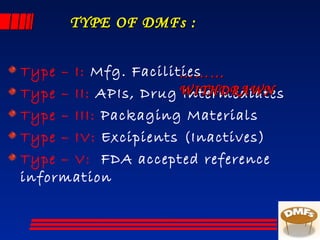

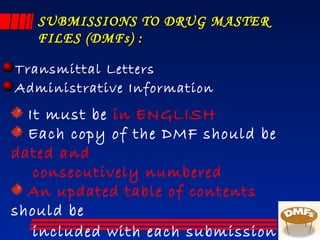

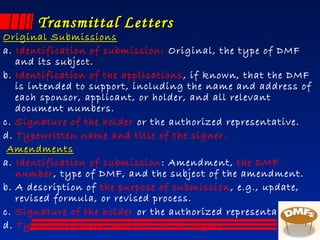

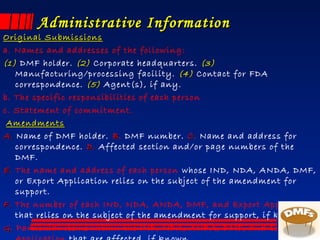

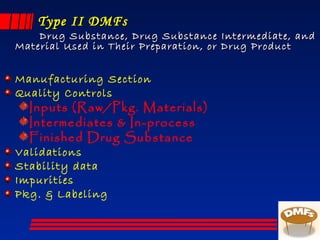

The document discusses Drug Master Files (DMFs), which provide confidential detailed information to the FDA in support of applications. It defines 5 types of DMFs and outlines their typical contents. These include manufacturing processes and facilities, active pharmaceutical ingredients, packaging materials, excipients, and reference information. The summary provides guidelines on submitting DMFs, required content for each type, quality controls, stability testing, and the FDA review process. Holders must adhere to good manufacturing practices and be willing to allow inspections.

![QUALITY CONTROLS’ SECTIONQUALITY CONTROLS’ SECTION

(contd.)(contd.)Complete Analytical Data of study batches

(Certificates of Analyses)

Sampling Procedures adopted

[Idea: Ensure “homogeneity of[Idea: Ensure “homogeneity of

test lots”]test lots”]

Analytical Reference Standard (ARS):

Preparation, Purification & Qualification with

Pharmacopoeial std.)

If Non-Pharmacopoeial: Extensive testing

Test batches vs. ARS: IR/UV/NMR/XRD](https://image.slidesharecdn.com/drugmasterfiles-121212135719-phpapp02/85/Drug-master-files-16-320.jpg)